A test paper continuous printing production system

A production system and test paper technology, applied in printing, printing machine, rotary printing machine, etc., can solve the problem of low printing efficiency of test paper, and achieve the effect of simple structure, strong continuity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below by means of specific embodiments:

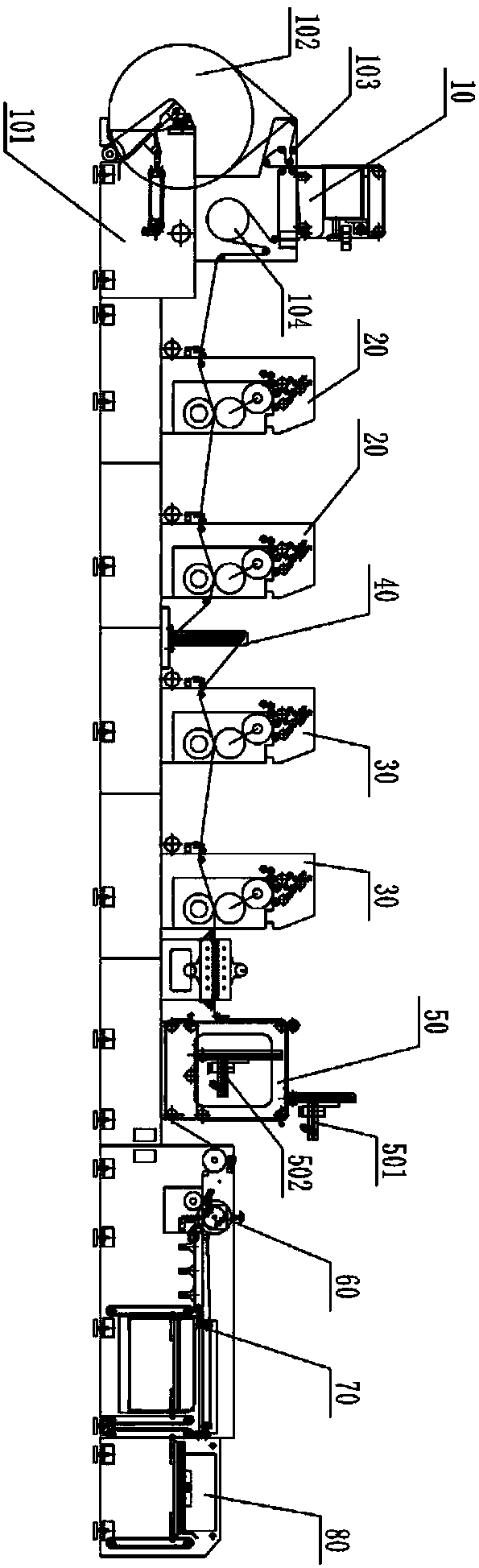

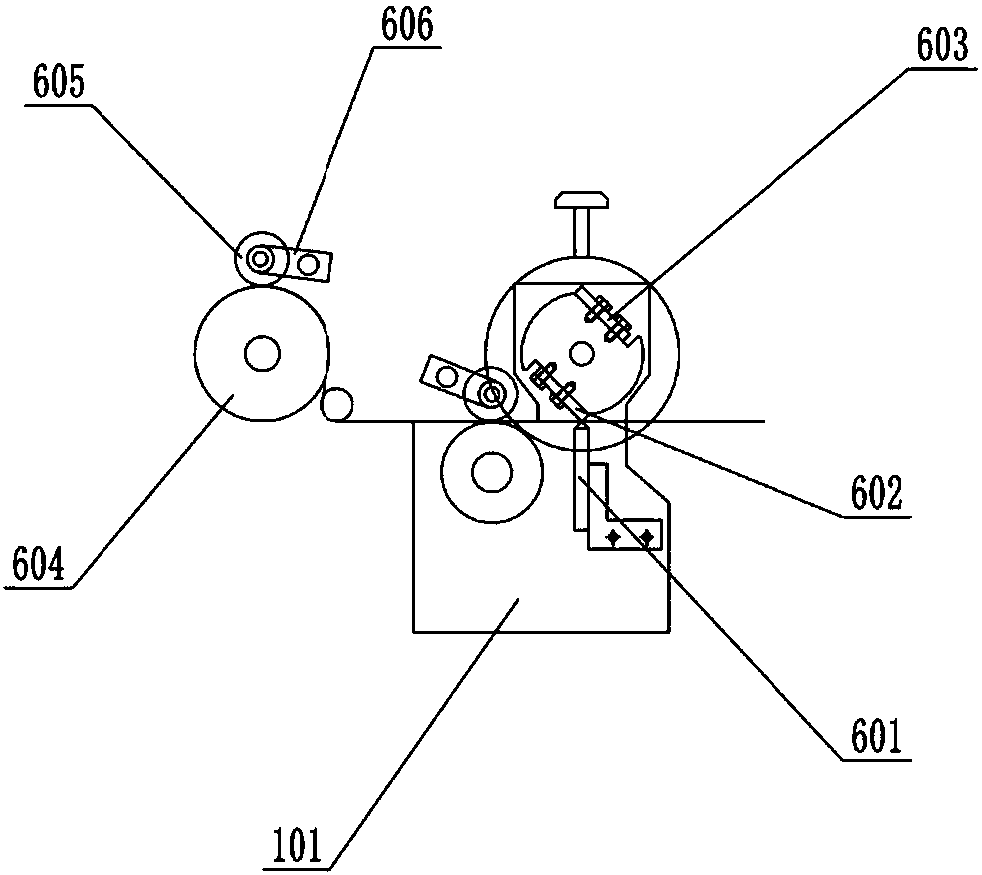

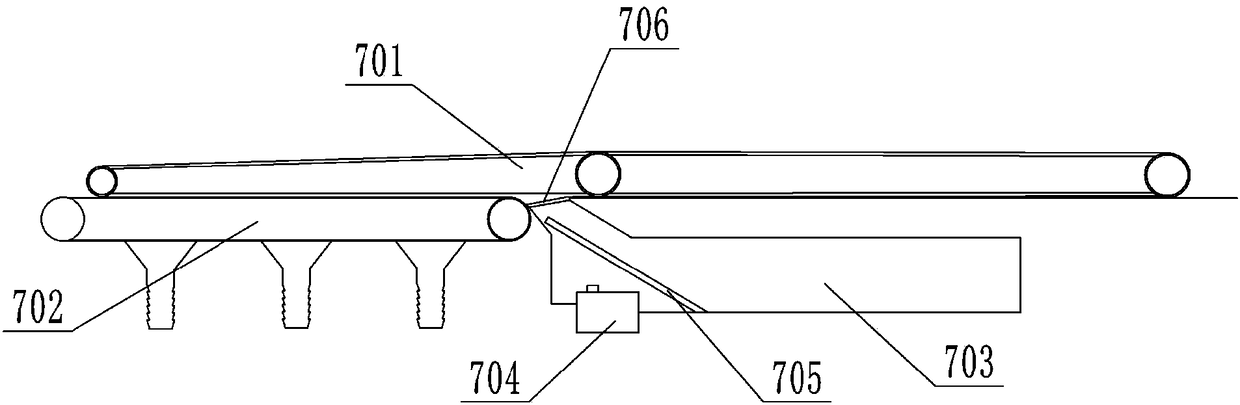

[0037] The reference numerals in the accompanying drawings of the description include: paper unloading mechanism 10, frame 101, cylinder 102, guide roller 103, paper fine-tuning device 104, first printing color group 20, second printing color group 30, turning mechanism 40, monitoring Mechanism 50, first CCD image sensor 501, second CCD image sensor 502, cutting mechanism 60, fixed cutter 601, first rotating cutter 602, second rotating cutter 603, traction wheel 604, pressing wheel 605, Connecting rod 606, error correction and rejecting mechanism 70, first conveyor belt 701, second conveyor belt 702, waste paper box 703, induced draft fan 704, guide plate 705, ventilation plate 706, collection box 80, first cavity 91, second cavity Cavity 92, first sealing ball 93, second sealing ball 94, spring 95, partition 96.

[0038] Such as figure 1 As shown, the basic solution of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap