A long afterglow luminescent material and its preparation method

A long afterglow luminescence and selected technology, which is applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of no long afterglow luminescence in the base material, no patent application for afterglow materials, etc., and achieves high afterglow intensity, improved afterglow performance, Combining simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: 0.99CaO·Sc 2 o 3 0.02ZrO 2 0.01CeO 2 Synthesis of Long Afterglow Materials

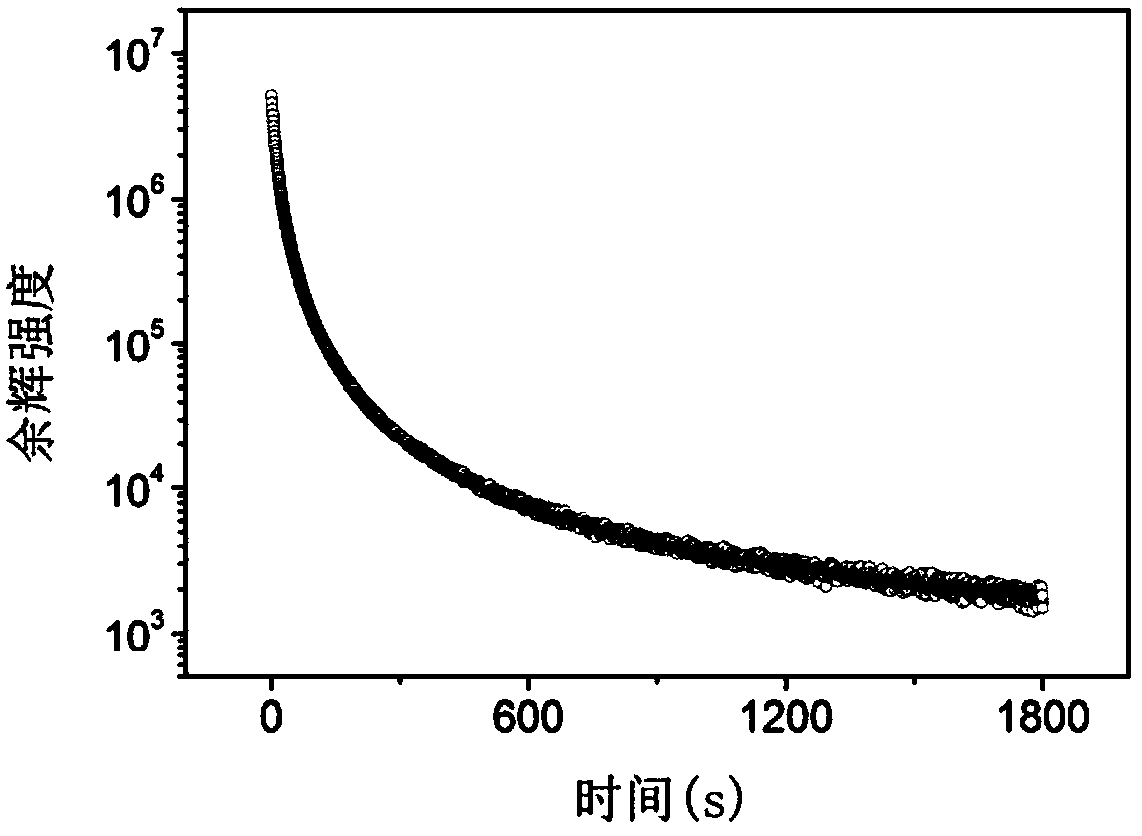

[0027] Weigh 1.1104g of CaO, 2.7584g of Sc 2 o 3 , 0.0493g of ZrO 2 and 0.0344 g of CeO 2 , after fully grinding in an agate mortar and mixing evenly, sintering in two steps: first, pre-sintering at a lower temperature of 500°C for 5 hours, cooling to room temperature, taking it out and grinding again and mixing evenly, and sintering at 1200°C for 8 hours under a carbon monoxide atmosphere . The sample is taken out and ground to finally obtain the sample. After being irradiated with ultraviolet light to blue light, the sample emits a strong long afterglow, and about 30 minutes after the excitation stops, the long afterglow luminescence phenomenon of the sample is still visible to the naked eye. The Ce produced in embodiment 1 3+ For the decay curve of afterglow luminescence over time of doped long-lasting luminescent materials figure 1 .

Embodiment 2

[0028] Example 2: 0.56CaO 1.2Sc 2 o 3 0.4ZrO 2 0.03CeO 2 0.02Dy2 o 3 0.002GeO 2 Synthesis of Long Afterglow Materials

[0029] Weigh 1.121g of CaCO 3 , 3.3101g of Sc 2 o 3 , 0.9858g of ZrO 2 , 0.0344g of CeO 2 , Dy of 0.1492g 2 o 3 and 0.0042g of GeO 2 , after fully grinding and mixing in an agate mortar, sintering in two steps: first, pre-sintering at a lower temperature of 800°C for 3h, cooling to room temperature, taking it out and grinding again and mixing evenly, and sintering at 1500°C for 8h under carbon reduction . The sample is taken out and ground, and the sample is finally obtained. After being irradiated with ultraviolet light to blue light, the sample emits a strong long afterglow.

Embodiment 3

[0030] Example 3: 0.5CaO 0.2MgO 0.6SrO 0.1BaO 1.1Sc 2 o 3 0.2ZrO 2 0.02CeO 2 0.01Dy 2 o 3 0.01Nd 2 o 3 0.01Pr 2 o 3 ·0.01Cr 2 o 3 0.01GeO 2 Synthesis of Long Afterglow Materials

[0031] Weigh 1.0009g of CaCO 3 , 0.1612g of MgO, 3.1639g of Sr(C 2 o 4 ) 2 , 0.5226g of Ba(NO 3 ) 2 , 3.0342g of Sc 2 o 3 , 0.4929g of ZrO 2 , 0.0688g of CeO 2 , 0.0746g of Dy 2 o 3 , 0.0673g of Nd 2 o 3 , 0.066g of Pr 2 o 3 , 0.0304g of Cr 2 o 3 and 0.0209 g of GeO 2 ,, after fully grinding and mixing in an agate mortar, sintering in two steps: first, pre-sintering at a lower temperature of 850°C for 2 hours, cooling to room temperature, taking out and grinding again and mixing evenly, in a mixed atmosphere of hydrogen and nitrogen Sinter at 1550°C for 9h. The sample is taken out and ground, and the sample is finally obtained. After being irradiated with ultraviolet light to blue light, the sample emits a strong long afterglow.

[0032] The long afterglow luminescent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com