A micro-volume automatic fat supply device for testing

A test and fat supply technology, which is applied in the direction of material inspection products, analytical materials, instruments, etc., can solve the problems of low fat supply speed and discontinuous fat supply, and achieve the effects of stable fat supply speed, saving time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

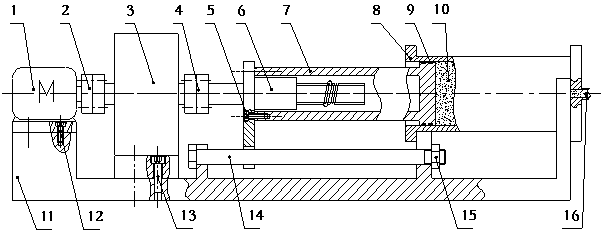

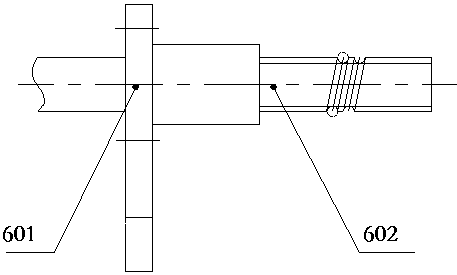

[0027] Such as figure 1 shows a micro-volume automatic grease supply device for testing, which specifically includes a base (11), a servo motor (1), a coupling A (2), a coupling B (4), a reducer (3), a ball nut Lead screw (6), guide rod (14), piston (7), grease bucket (8), sealing ring (9), screw A (5), screw B (12), screw C (13), nut (15 ).

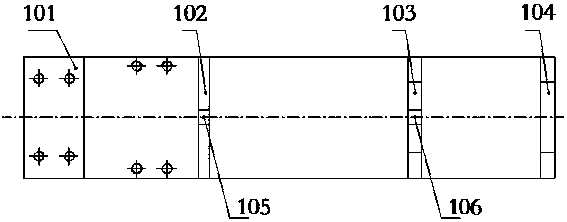

[0028] There is a step surface (101) at the left end of the base (11), and a threaded hole is processed on the step surface (101); there is a column (102) on the right side of the step surface (101), and a U-shaped groove is processed in the middle of the column (102) (105); the right side of the column (102) is processed with bracket A (103) and bracket B (104) for fixing the grease bucket (8); the bottom surface of the base (11) is processed with four threaded holes and a reducer (3) Connection.

[0029] The se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap