A rolling friction life test device based on interface friction performance monitoring

A technology of interface friction and testing equipment, which is applied in the direction of testing wear resistance and mechanical bearing testing, etc., can solve the problems that the actual state simulation of rolling bearings is not particularly suitable, the friction and wear process of rolling bearings cannot be effectively simulated, and the device system is complex, etc. load phenomenon, realize online health status monitoring, and have the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing.

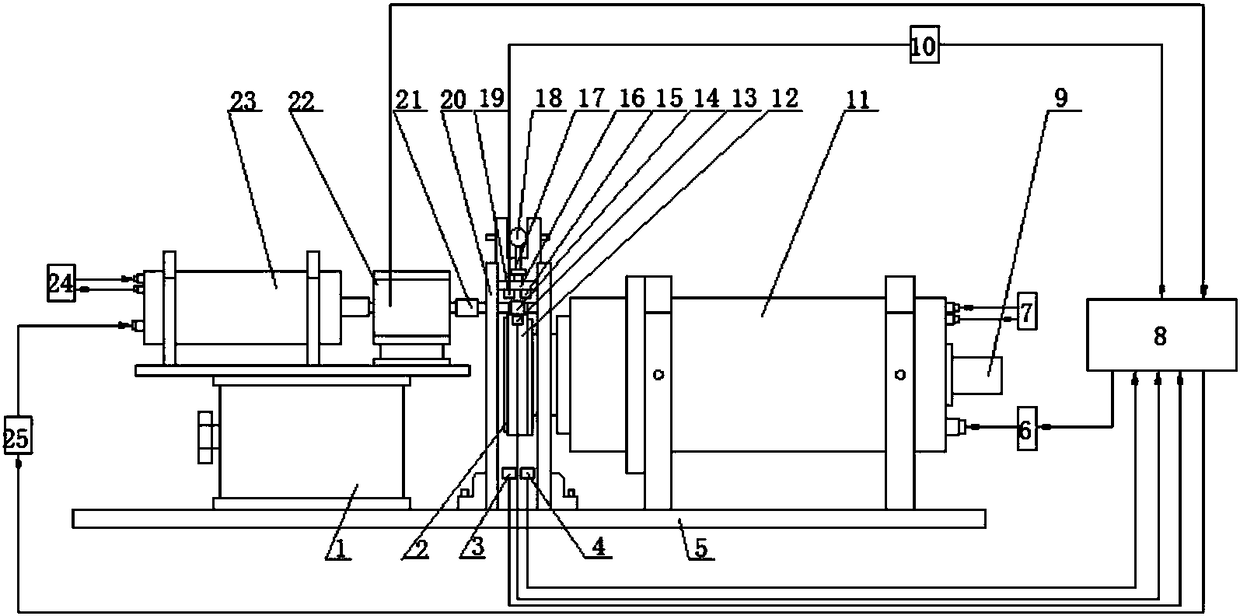

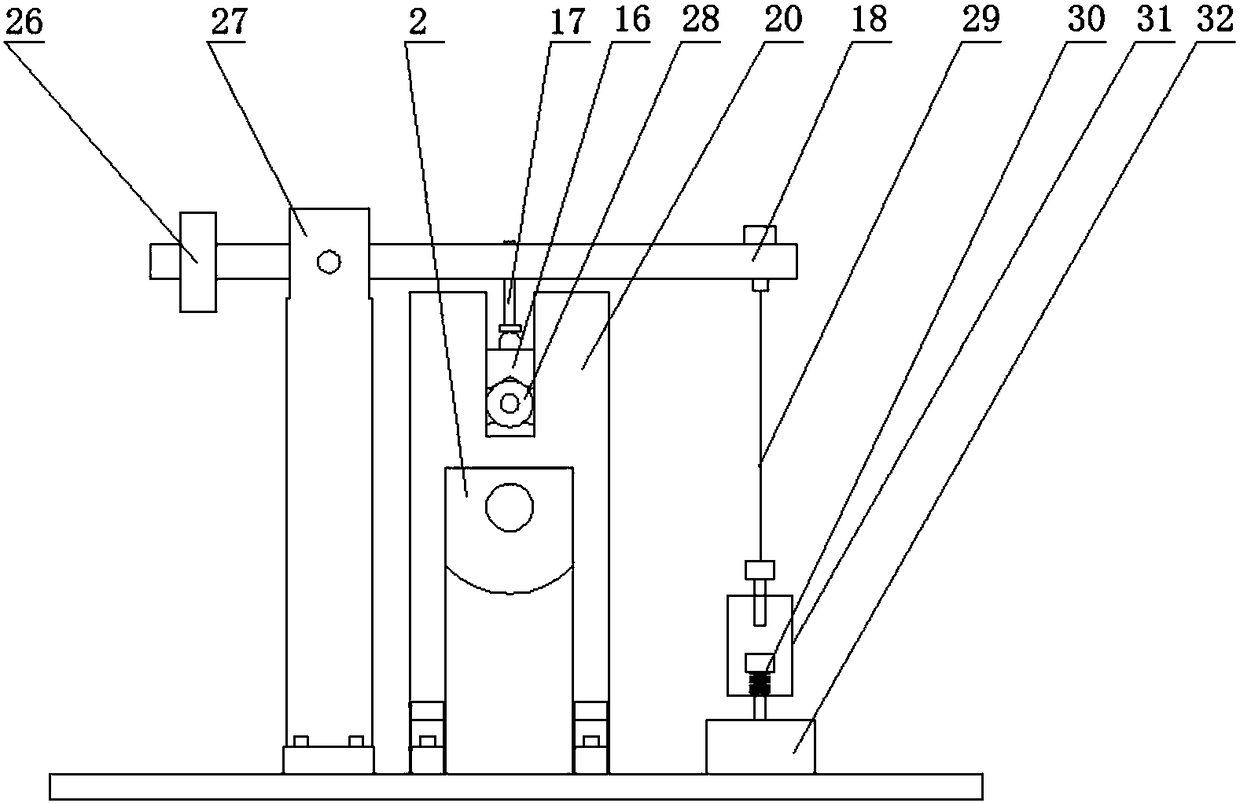

[0028] refer to figure 1, a rolling friction life testing device based on interface friction performance monitoring, comprising a bracket 5, one end of the bracket 5 is fixed with a lifting platform 1, a high-speed electric spindle 23 is arranged on the lifting platform 1, the front end of the high-speed electric spindle 23 and the torque One end of the sensor 22 is connected; the high-speed electric spindle 23 and the torque sensor 22 are fixed on the platform of the lifting platform 1 and can move up and down with the adjustment of the lifting platform; the other end of the torque sensor 22 is connected to the measured object through the elastic coupling 21 Replaceable rolling body 14; during the installation process, it is necessary to ensure the coaxiality of the axis of the high-speed electric spindle 23, the axis of the torque sensor 22 and the axis of the rolling body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com