Method for optimizing automobile instrument cross beam

A technology of an automobile dashboard and an optimization method, which is applied in the directions of motor vehicles, transportation, and packaging, can solve the problems of idling jitter of the steering wheel, unreasonable design of the dashboard beam, and concentrated steering stress, and achieves weight reduction, high structural strength, and realization of The effect of functional design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Optimization steps for car dashboard beams:

[0039] 1) Select the main material of the beam;

[0040] 2) Determine the main mounting bracket;

[0041] 3) Adjust the overall stiffness of the instrument panel beam;

[0042] 4) Increase the first-order frequency of the beam;

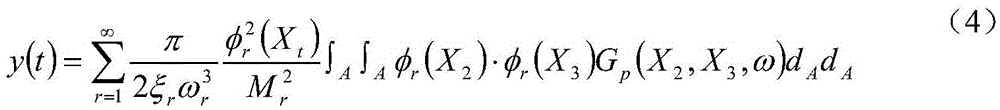

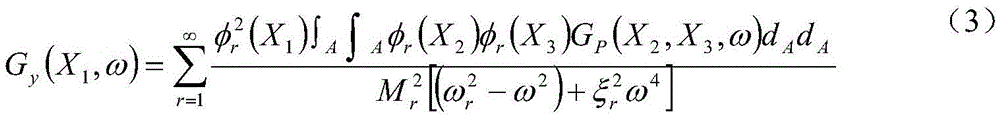

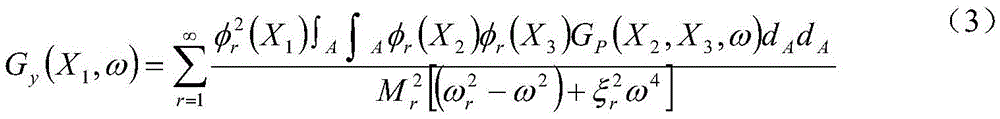

[0043] 5) Use ABAQUS and NASTRAN tools for analysis: suspend the instrument panel beam flexibly, use the exciter as the excitation source, select 30 points on the instrument panel beam for vibration pickup, and test the direction perpendicular to the normal direction of each measuring point of the car door;

[0044] 6) Carry out grid division: the basic data beam body model is divided into grids under constraint conditions;

[0045] 7) In the stage of grid division, use the pre-processing software to process the grid: focus on dividing the solder joints, the joints of the sub-supports, the joints of the rounded corners and reinforcing ribs, and modify the deformed grid holes; handled evenly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com