Noise reduction panels, motors and air conditioners

A technology of muffler plate and plate body, which is applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problem of high working noise of the compressor, reduce airflow noise, solve the problem of high working noise, eliminate and airflow effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

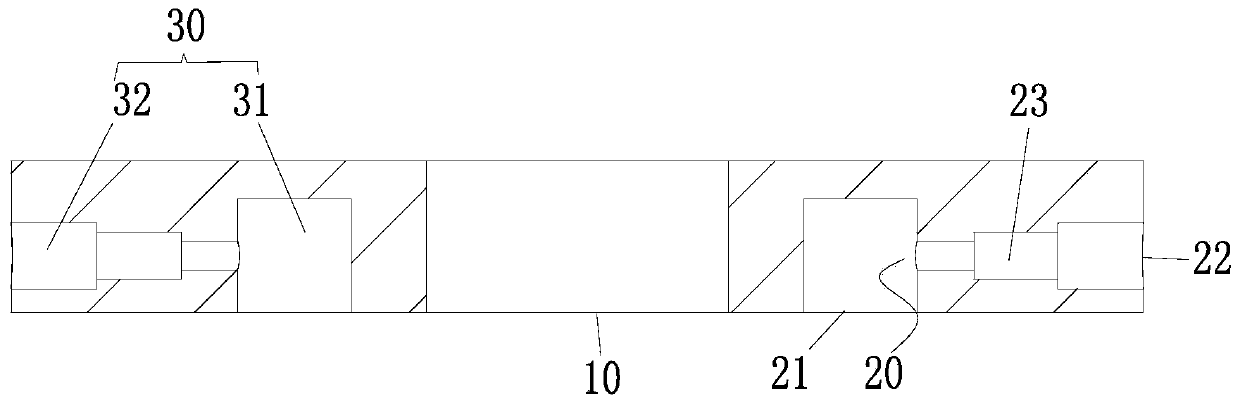

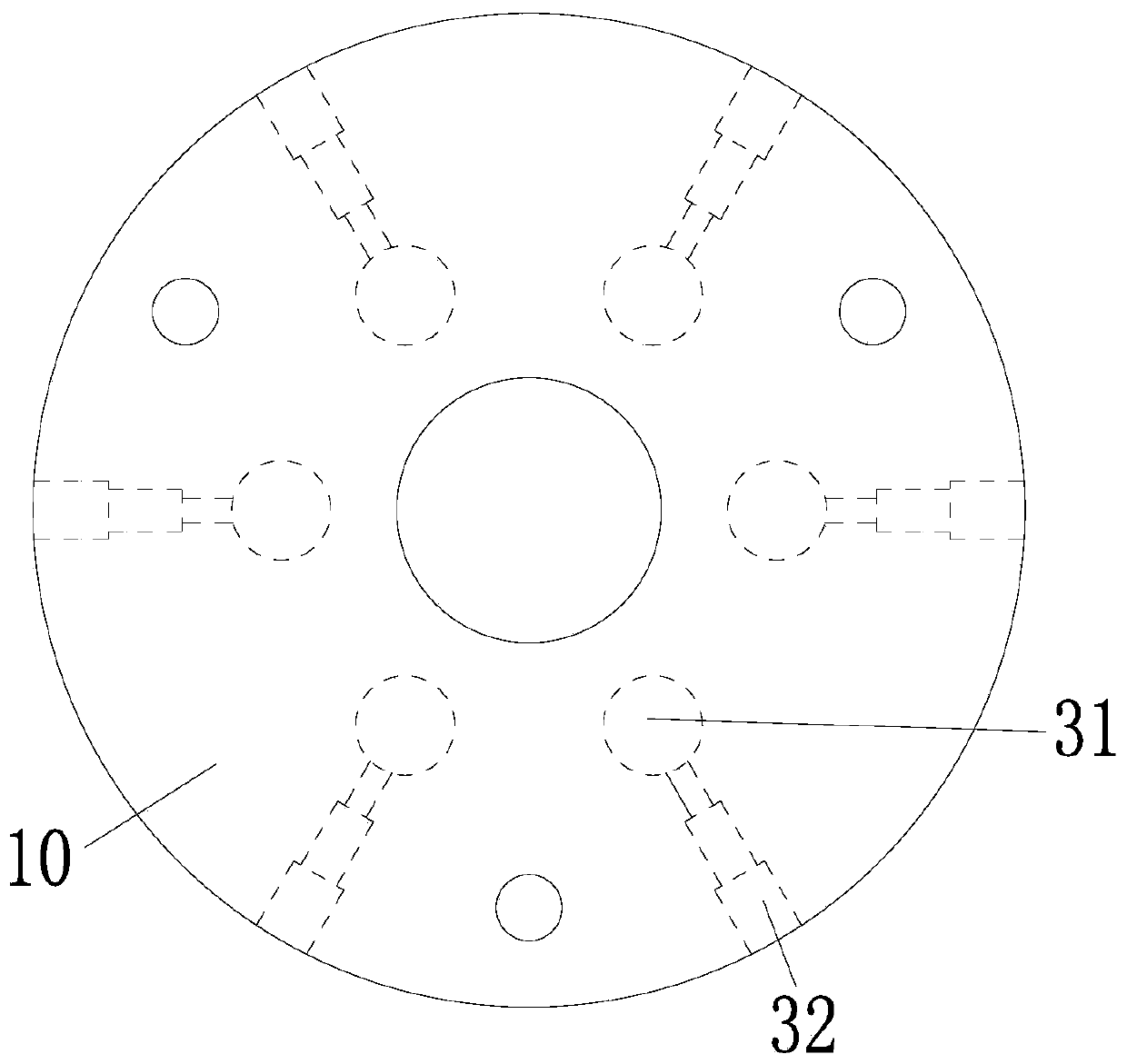

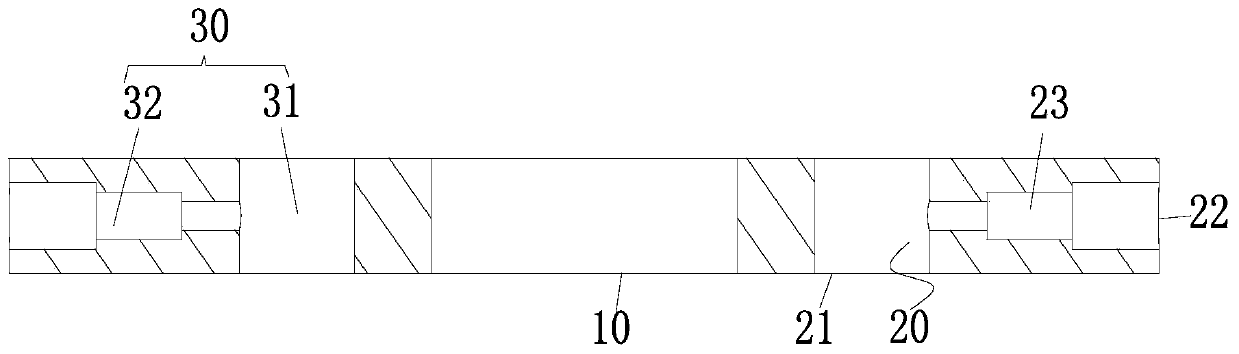

[0031] Compressor noise is not only a key technical indicator, but also a yardstick for direct user experience. At the same time, noise reduction design, especially fluid noise reduction design, has always been a difficult point for compressors. Especially after the air conditioner is converted to direct current, the frequency conversion drive of the compressor makes the air flow noise a bottleneck in the improvement of the compressor design. Because the noise comes from the work done by the pump body of the compressor on the fluid, the conventional noise reduction methods are to design orifices (such as Helmholtz resonance chamber) and shape design of the muffler on the pump body machinery. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com