Full-automatic micro counter weight material sorting device

A fully automatic, weight-counting technology, applied in packaging, solid materials, transportation and packaging, etc., can solve problems such as affecting product quality, substandard packaging weight, and cumbersome weighing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

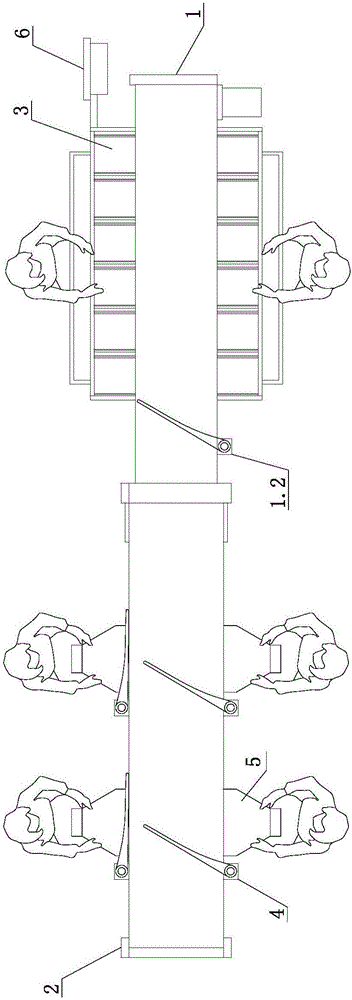

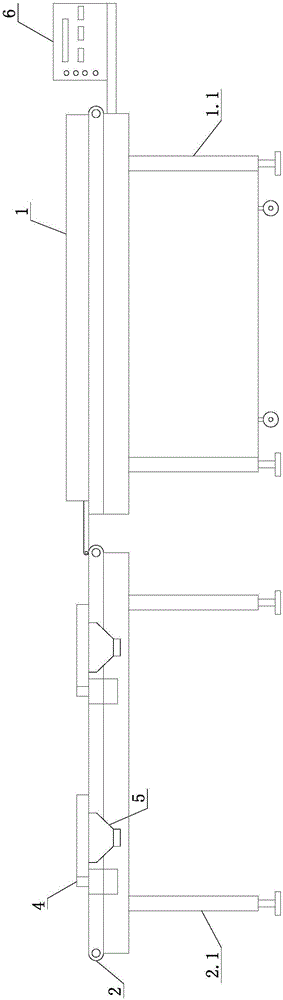

[0026] like figure 1 and figure 2 A fully automatic micro-counterweight sorting device shown includes: a first-stage conveyor belt 1, a second-stage conveyor belt 2, a single weighing unit 3, an automatic baffle 4, a discharge port 5 and a computer controller 6;

[0027] A first-stage conveyor belt support 1.1 for supporting and fixing the first-stage conveyor belt 1 is arranged below the first-stage conveyor belt 1;

[0028] The number of individual weighing units 3 is more than 6, and each individual weighing unit 3 is fixed on the first-stage conveyor belt bracket 1.1, and is evenly distributed on both sides of the first-stage conveyor belt 1 conveying surface;

[0029] The computer controller 6 is fixed on the first stage conveyor belt bracket 1.1;

[0030] The single weighing unit 3 is a small weighing conveyor belt, and the weighing data of the single weighing unit 3 is transmitted to the computer controller 6 through a line;

[0031] A second-stage conveyor belt br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com