A cascaded electro-hydraulic servo system control method and system based on coupling disturbance observer

An electro-hydraulic servo system and electro-hydraulic servo technology are applied in the direction of fluid pressure actuation system components, instruments, and electrical digital data processing, etc., which can solve the problems of reduced control accuracy and great influence on the dynamic response performance of joint motion tracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

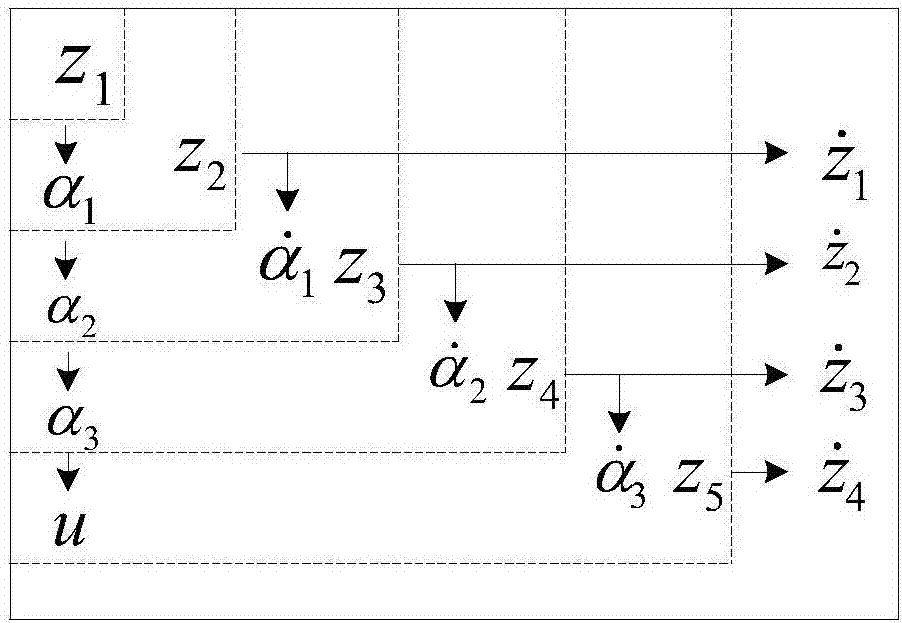

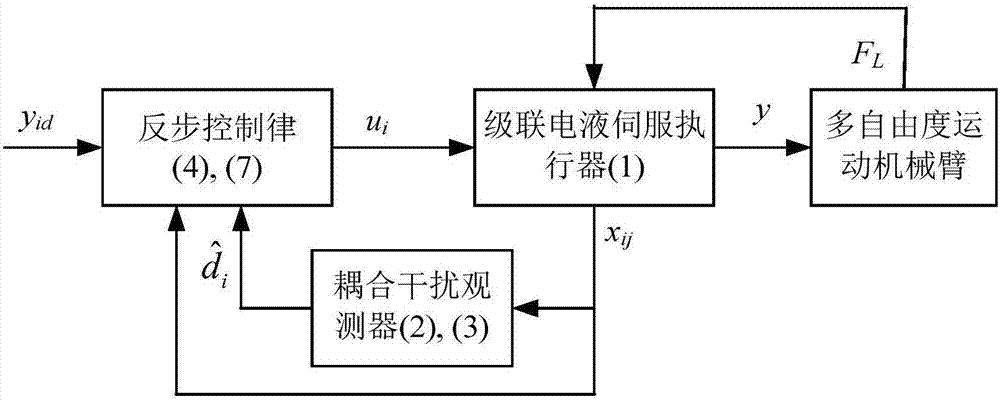

[0039] The following provides a specific real-time method of the electro-hydraulic servo-driven cascaded mechanical arm mechanism based on the coupling disturbance observer and the backstepping control method of the present invention.

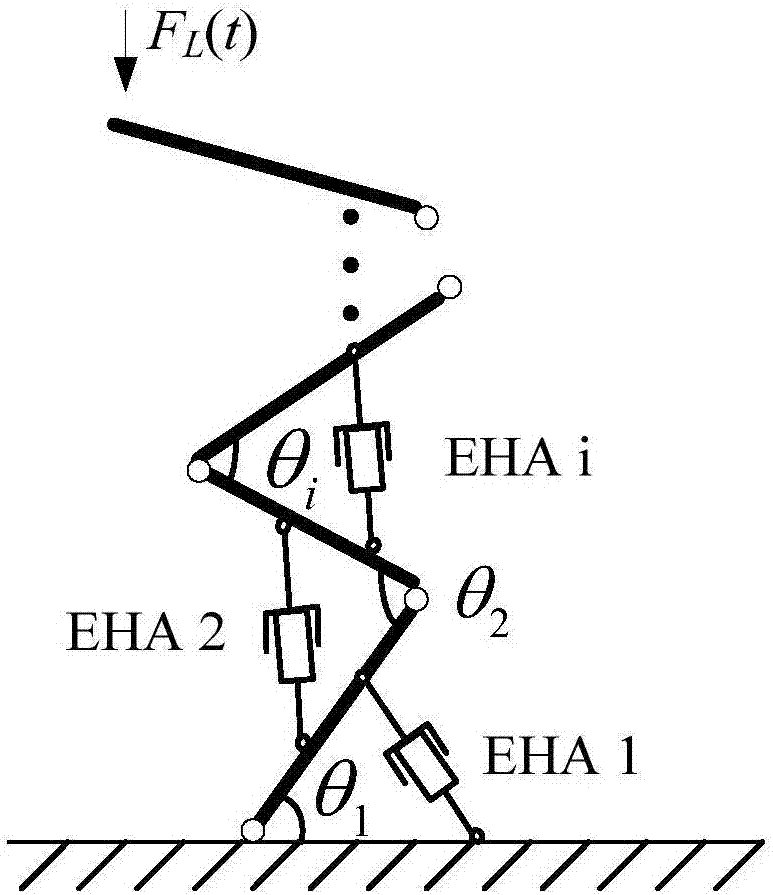

[0040] The model of the electro-hydraulic servo actuator is a 4th-order model. The model of the mechanical arm mechanism movement is not considered. The joint torque required for the mechanical arm movement is considered as the load disturbance of the electro-hydraulic servo actuator. The brief description is as follows:

[0041] 1) Modeling of electro-hydraulic servo actuator

[0042] A fourth-order model is used to describe the electro-hydraulic servo actuator model of the hydraulic cylinder circuit driven by the servo valve as follows:

[0043]

[0044] i=1,...n

[0045] in is the fourth-order model state variable of the i-th cascaded electro-hydraulic servo actuator, y i is the output displacement of the i-th hydraulic cylinder, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com