Electro-hydraulic servo control method based on fading memory filtering and 2-DOF mechanical arm

An electro-hydraulic servo and attenuation memory technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of uncertain parameter constants, inability to estimate time-varying parameters, external interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

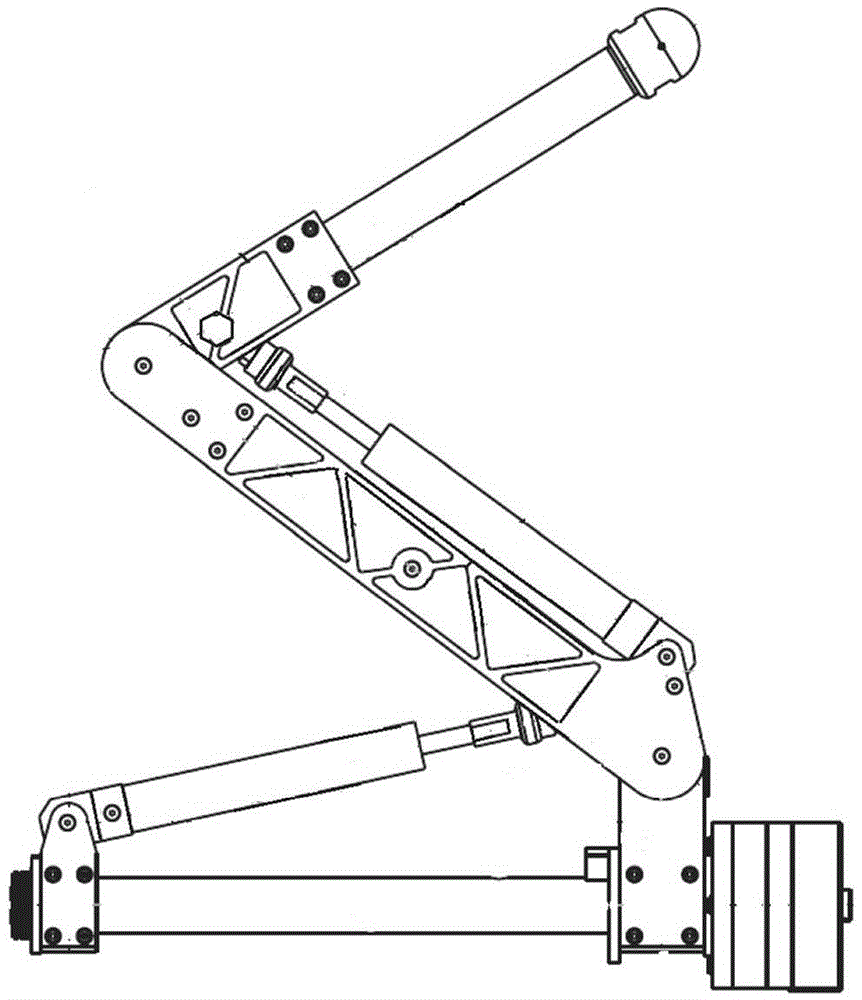

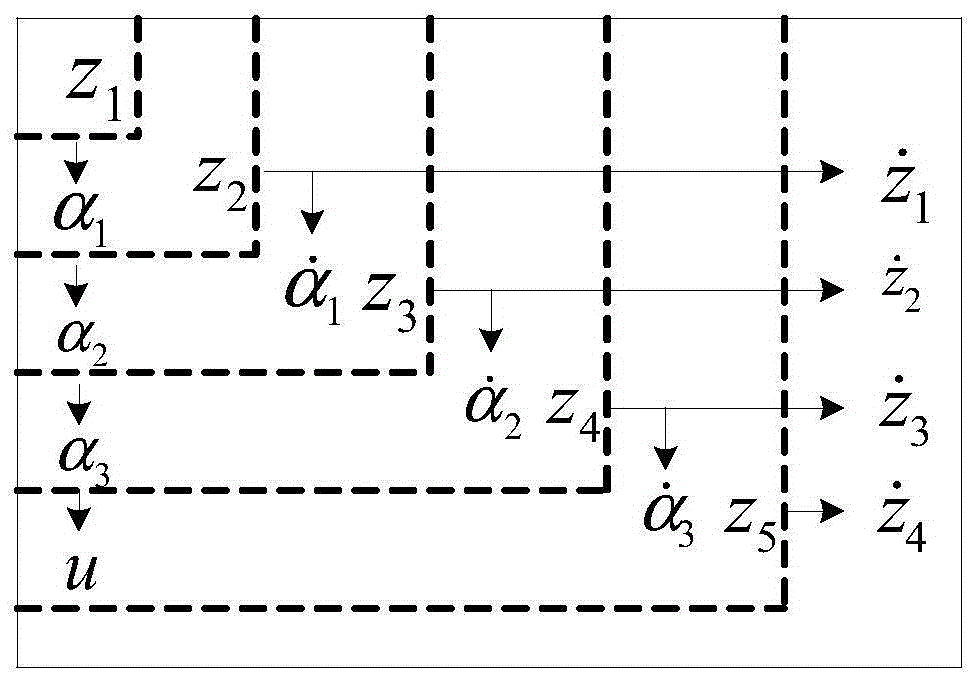

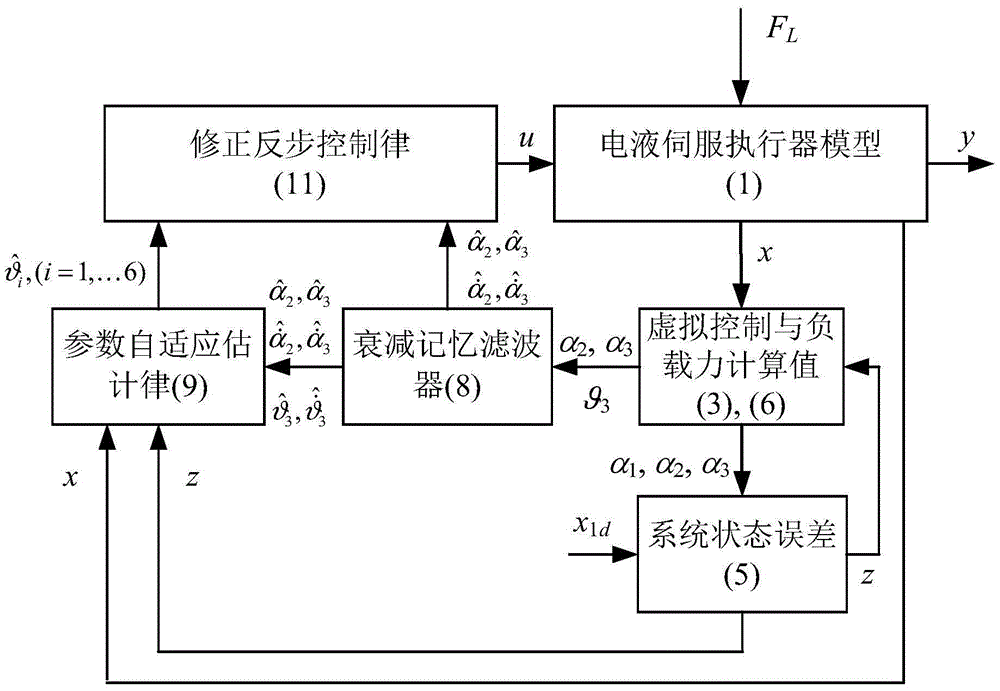

[0038] The following provides a specific real-time manner of the 2-DOF robotic arm motion control device based on the attenuation memory filter and the parameter adaptive estimation method of the present invention.

[0039] The model of the whole system is divided into two parts, including the model of electro-hydraulic servo actuator and the load force model of 2-DOF manipulator. They are briefly described as follows:

[0040] 1) Modeling of electro-hydraulic servo actuator

[0041] The four-order model is used to describe the electro-hydraulic servo actuator model of the servo valve driving hydraulic cylinder circuit as follows:

[0042]

[0043] where x i (i=1,...,4) is the model state variable, y hydraulic cylinder output displacement, is the output displacement rate of change, p L is the load pressure, x v is the displacement of the spool of the servo valve, is an uncertain parameter, m is the load mass, p s is the oil supply pressure, A p is the cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com