multi-head oiler

A lubricator and multi-head technology, which is applied in the direction of lubricating oil containers, lubricating parts, mechanical equipment, etc., can solve the problems of unusable, poor compatibility of intelligent lubricators, oil filling, etc., and achieve convenient operation, wide range of oil adjustment, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

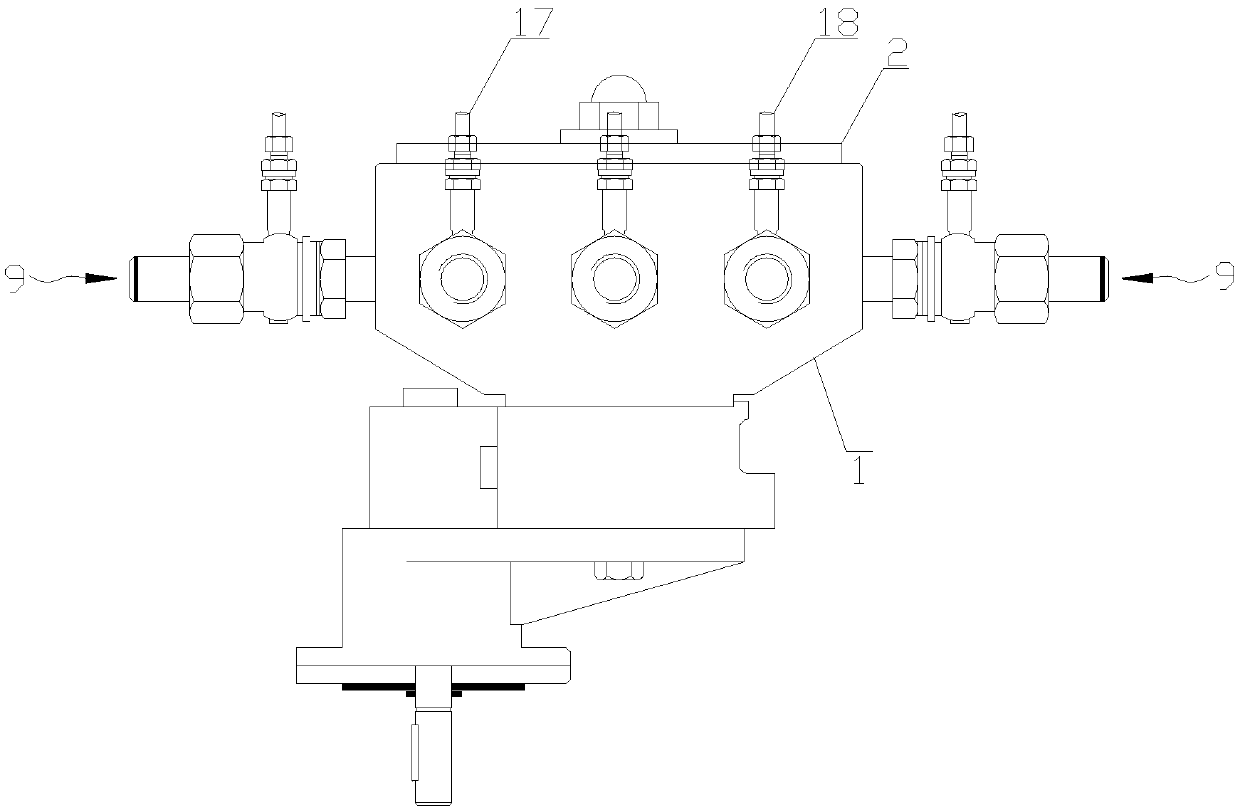

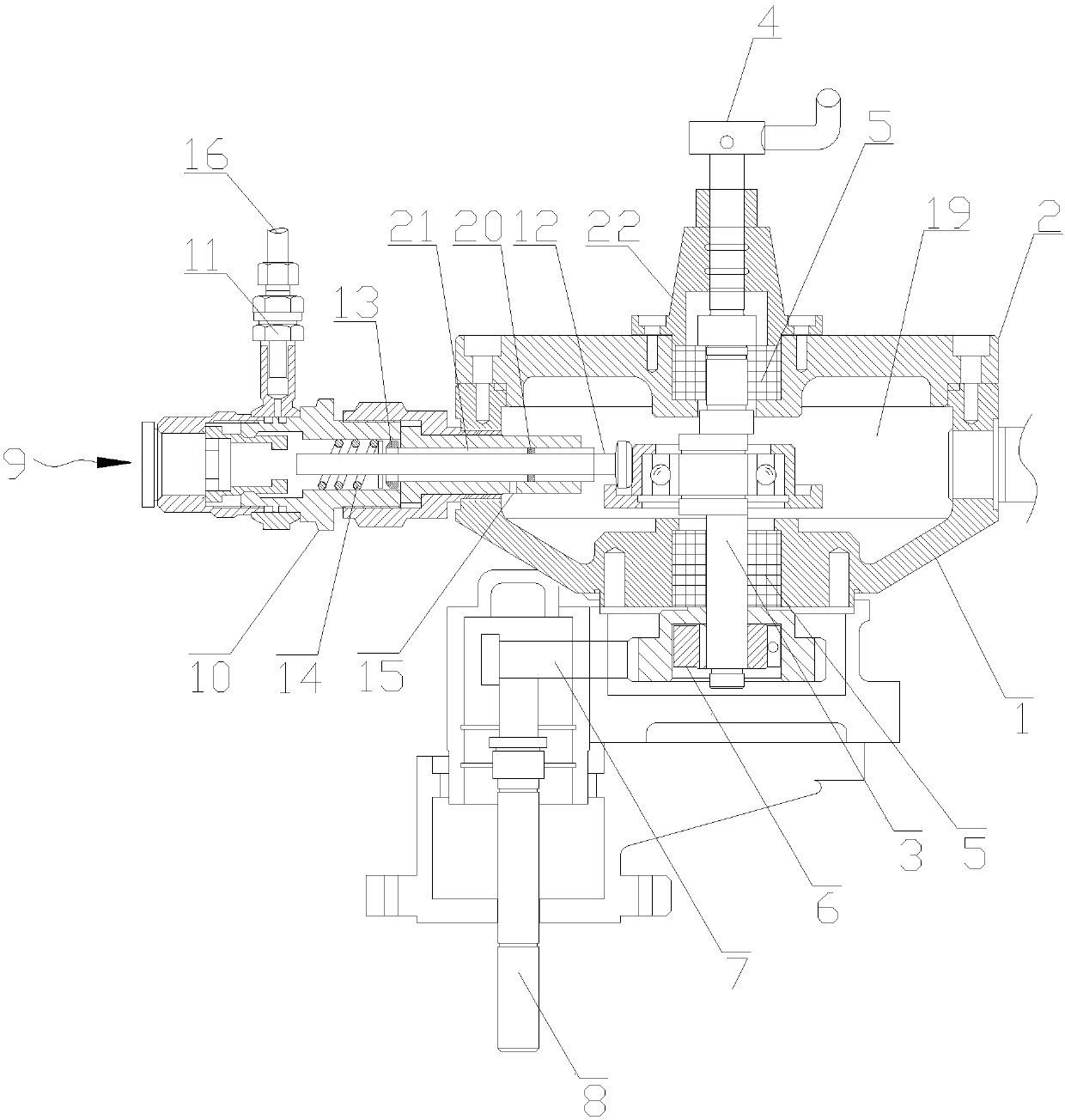

[0020] like Figure 1-2 As shown, a multi-head oiler includes a cylindrical shell 1 and a cover 2 sealed with the shell 1, the shell 1 and the cover 2 form a cavity 19, and oil pumps 9 are distributed at intervals on the outer circumference of the shell 1, 2-10 oil pumps 9 can be arranged at intervals on the outer circumference of the housing 1, an oil inlet 17 and a reserved oil return port 18 corresponding to the oil inlet 17 are arranged between adjacent oil pumps 9, and a cam is installed at the center of the housing 1 One end of the shaft 3 and the camshaft 3 pass through the cover body 2, and the other end is connected with the overrunning clutch 6 in the casing 1. A sealing device 5 is provided at the contact position between the camshaft 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com