Burner fire cover of gas cooker

A gas cooker and burner technology, which is applied to gas fuel burners, burners, combustion methods and other directions, can solve the problems of easy flame separation, high airflow speed, and the burner ignition is not stable enough, and achieves stable fire transmission and fire transmission. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

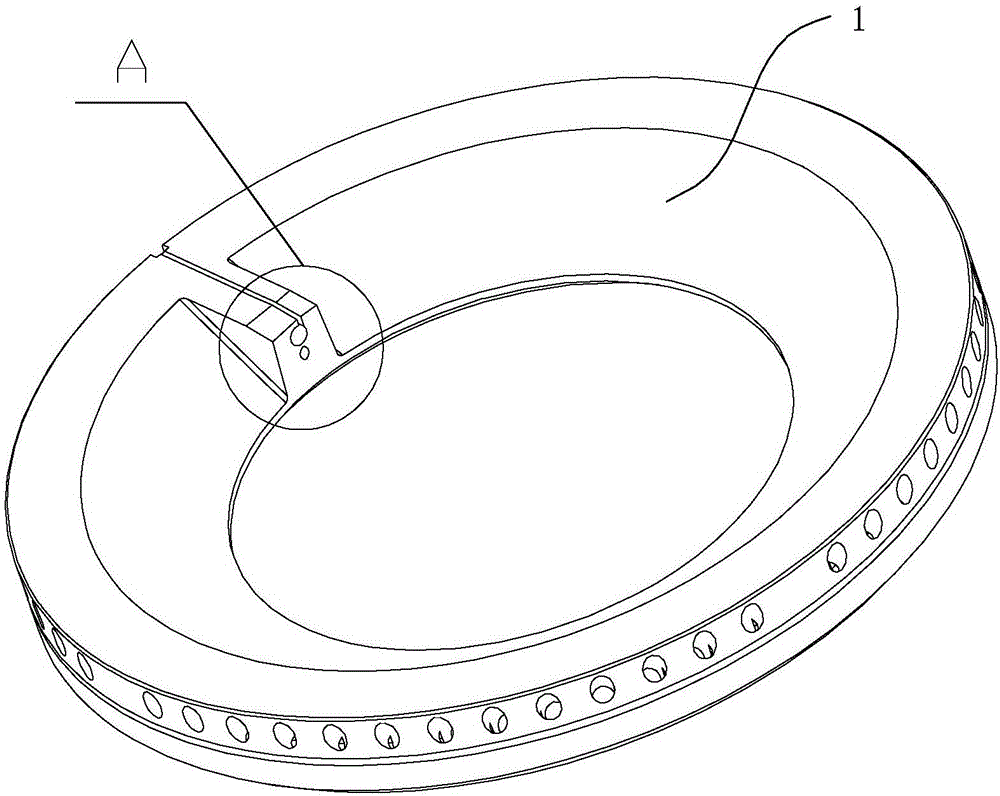

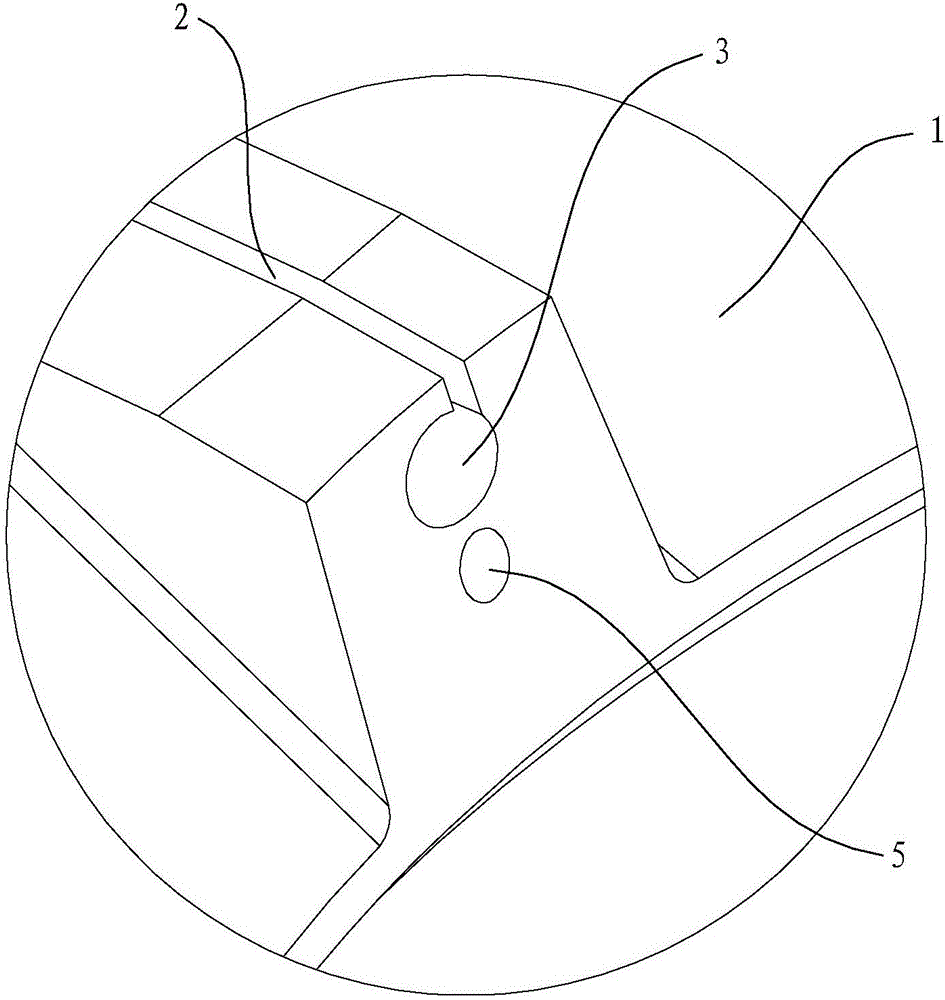

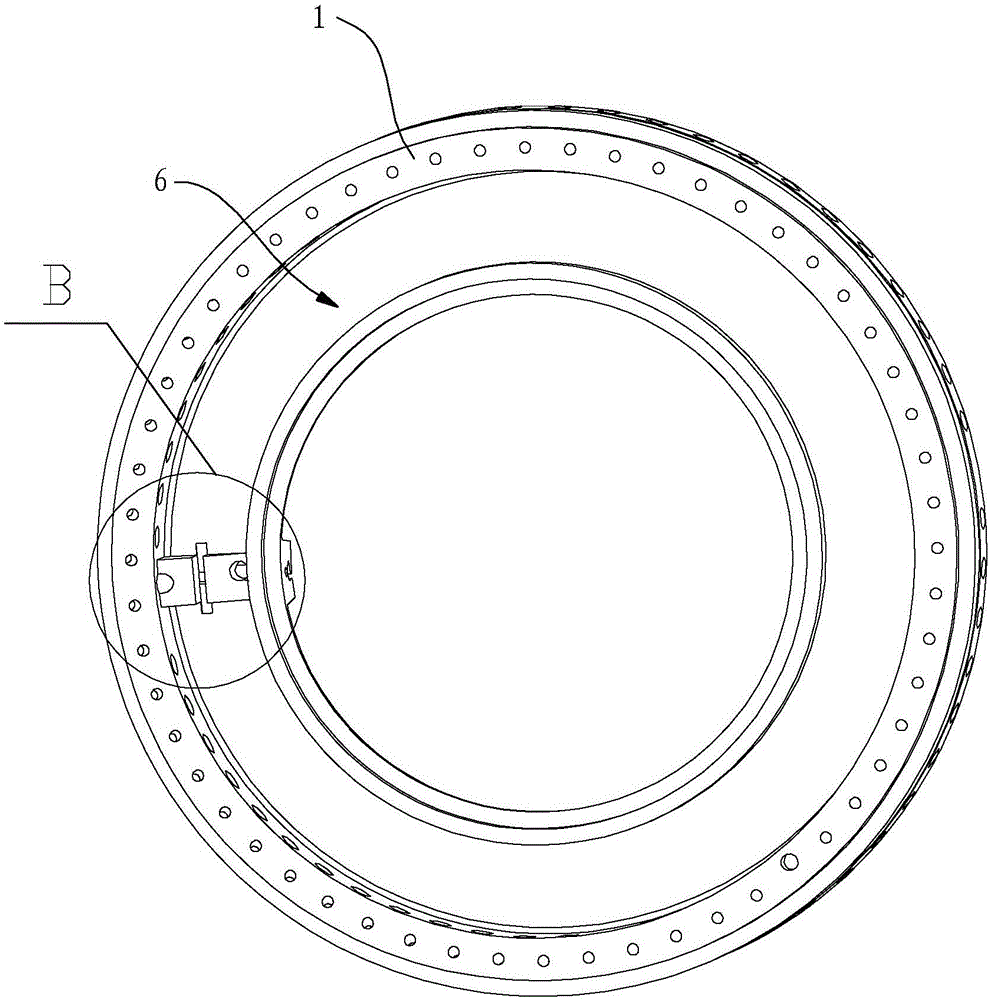

[0023] Such as Figure 1 to Figure 6 As shown, the burner fire cover of the gas cooker in this embodiment includes a circular fire cover body 1, the interior of the fire cover body 1 has an air mixing chamber 6, and a horizontally arranged fire cover body 1 is provided on the top of the fire cover body 1 The fire trough 2 has a horizontal straight hole 3 inside the fire cover body 1, and the straight hole 3 is located directly below the fire trough 2 and communicates with it. Moreover, the width of the horizontal straight hole 3 is greater than the width of the fire groove 2 , and the center line of the horizontal straight hole 3 points to the center of the outer circumference of the fire cover body 1 .

[0024] There is a through hole 4 on the fire cover body 1, and the through hole 4 is located below the horizontal straight hole 3 and has a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap