Bidirectional biomass gasification furnace

A gasifier and biomass technology, which is applied in the field of small household biomass two-way gasifiers, can solve the problems of complicated operation, difficult control, and harm to the health of users' families.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

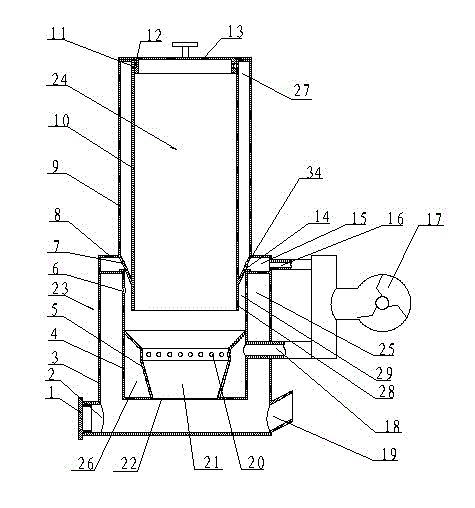

Embodiment 1

[0018] Such as figure 1 As shown, the two-way gasification furnace is composed of two parts: a two-way gasification chamber 23 and a barrel of rotating material 24. The hanging liner 4 is suspended on the outer casing 3 of the two-way gasification chamber 23, and a seal is formed between the outer casing 3 and the hanging inner bag 4. The gas chamber 25. There is an upper gas port 6 on the top of the suspension liner 4, and a lower gas port 21 at the bottom. The inner side of the lower part of the suspension liner 4 and the double-cone gas ring 5 form a fully enclosed air guide chamber 26, the air guide chamber 26 is connected to the blower 17 through the lower air guide pipe 18, and the middle part of the double-cone gas ring 5 has an oxygen supply hole 20, The bottom of the shell 3 of the two-way gasification chamber 23, that is, the bottom of the gas chamber 25, has an ash outlet 2 and an air outlet 19, the ash outlet 2 has an ash outlet cover 1, and the gas outlet 19 has ...

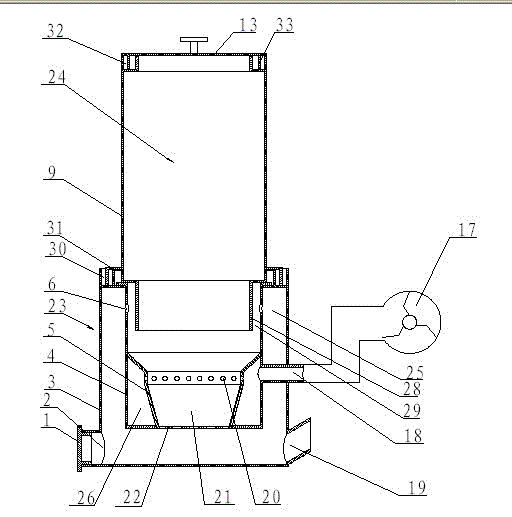

Embodiment 2

[0020] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 lies in the shape and structure of the rotating barrel 24 , the sealing method of the joint between the rotating barrel 24 and the casing 3 , and the sealing method of the top of the rotating barrel 24 . The top of the casing 3 is provided with a lower water seal groove 30, and the side of the rotary bucket 24 is provided with a lower water seal ring 31, which is fastened in the lower water seal groove 30; the rotary bucket 24 in this embodiment does not divide the material The lower part of the barrel shell and the barrel liner is stepped. After installation, the length of the lower end exceeds the upper gas port 6, and forms a sandwich layer 28 with the inner wall of the hanging liner 4; the upper end of the rotating barrel 24 is provided with an upper water seal The groove 32 and the feeding cover 13 have a downward material cover water sealing ring 33 , and the material cover water seal...

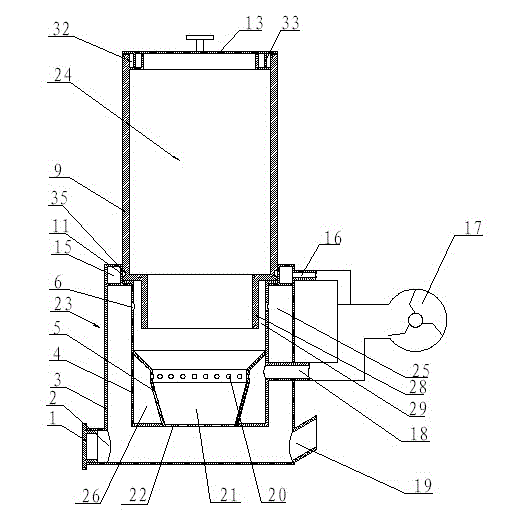

Embodiment 3

[0022] Such as image 3 As shown, the difference between Embodiment 3 and Embodiment 2 lies in the sealing method of the joint between the rotary cylinder 24 and the casing 3 . The top of the shell 3 is provided with a barrel air seal chamber 15, and the side of the rotating barrel 24 is provided with an annular barrel air seal groove 35, and the barrel air seal chamber 15 communicates with the barrel air seal groove 35 through the air seal hole 11, and passes through The upper air duct 16 communicates with the blower. Others are with embodiment 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap