Full-automatic steam-type ironing machine

A belt ironing machine, fully automatic technology, used in ironing machines, washing devices, textiles and papermaking, etc., can solve problems such as ribbon wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

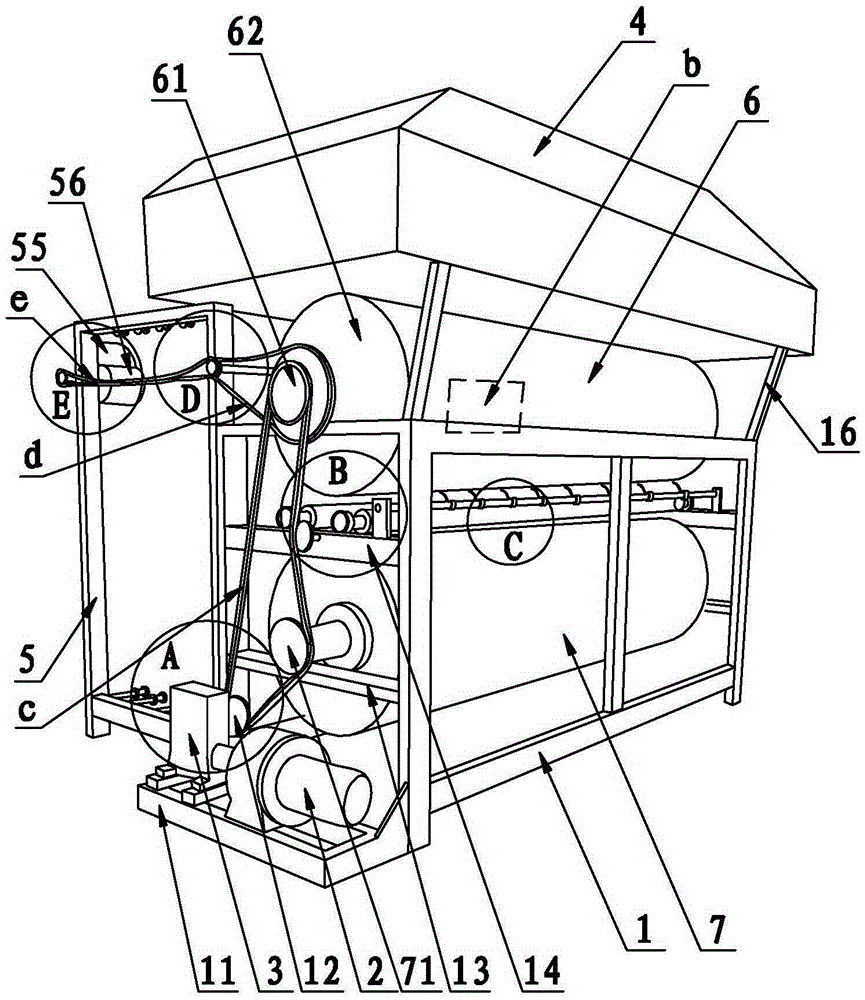

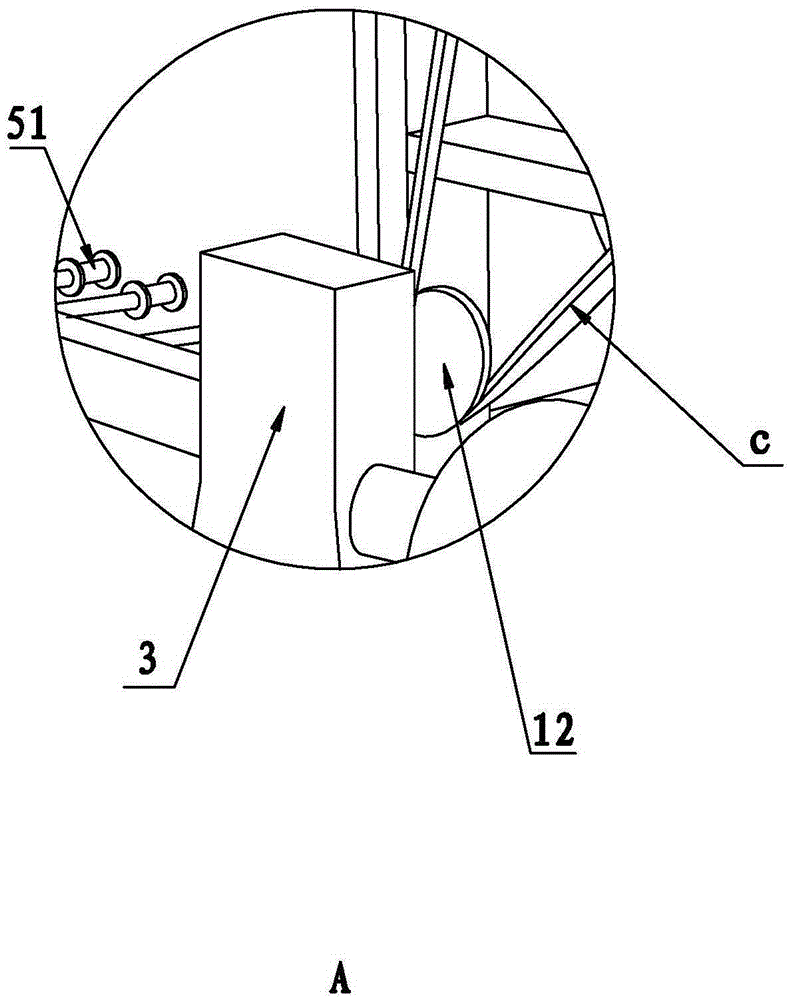

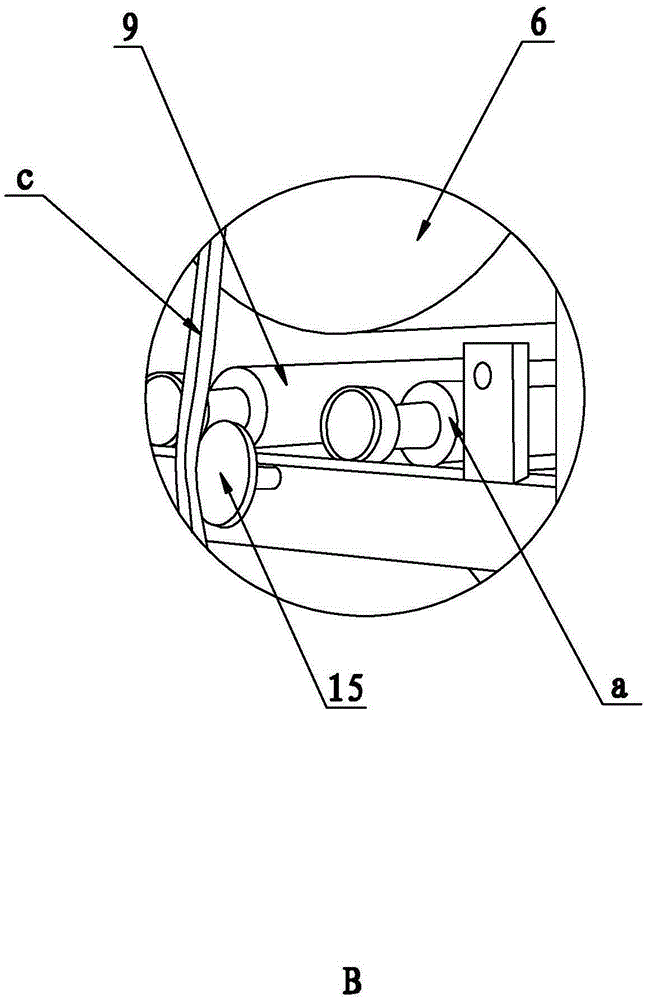

[0031] Such as Figure 1-6 As shown, a fully automatic steam ironing machine includes a frame 1, a motor 2, a gearbox 3, a top cover 4, a tape feed frame (not shown in the figure), a tape discharge frame 5, an upper roller 6, a lower Drum 7, guide frame 8, roller one 9, roller two a and controller b, described frame 1 is a rectangular frame structure, and the bottom of described frame 1 rear end is equipped with underframe 11, and described underframe 11 The middle part of the frame 1 is equipped with the motor 2, the gearbox 3 is connected with the motor 2, and the gearbox 3 is equipped with a gear 12; the middle and lower parts of the front and rear ends of the frame 1 are fixedly installed with a mounting plate 1 13. Bearings at the front and rear ends of the lower drum 7 are respectively mounted on the mounting plates 13 at the front and rear ends of the frame 1, and gears 2 71 are installed at the front and rear ends of the lower drum 7; the front and rear ends of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com