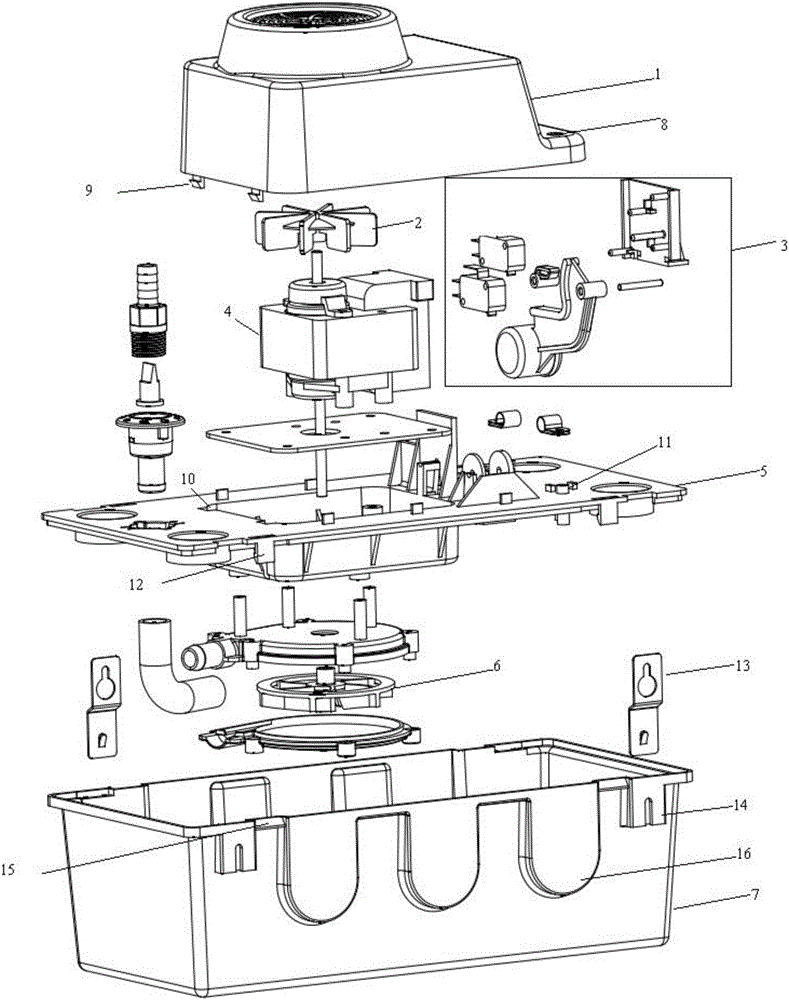

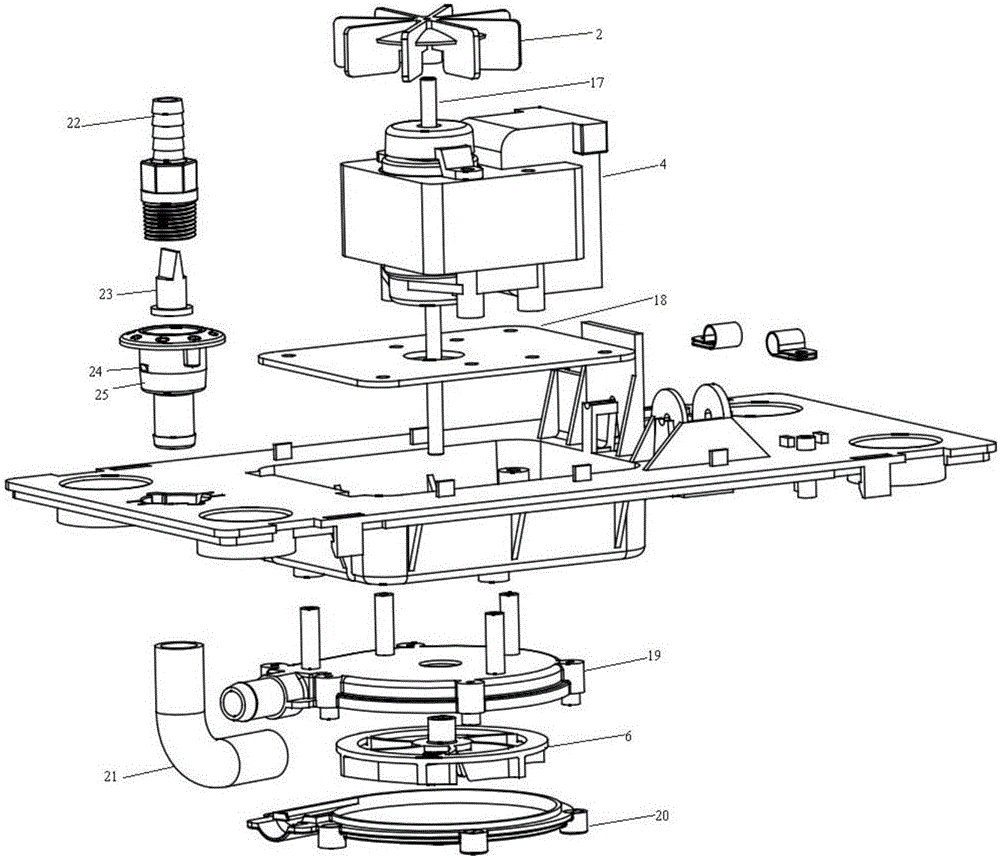

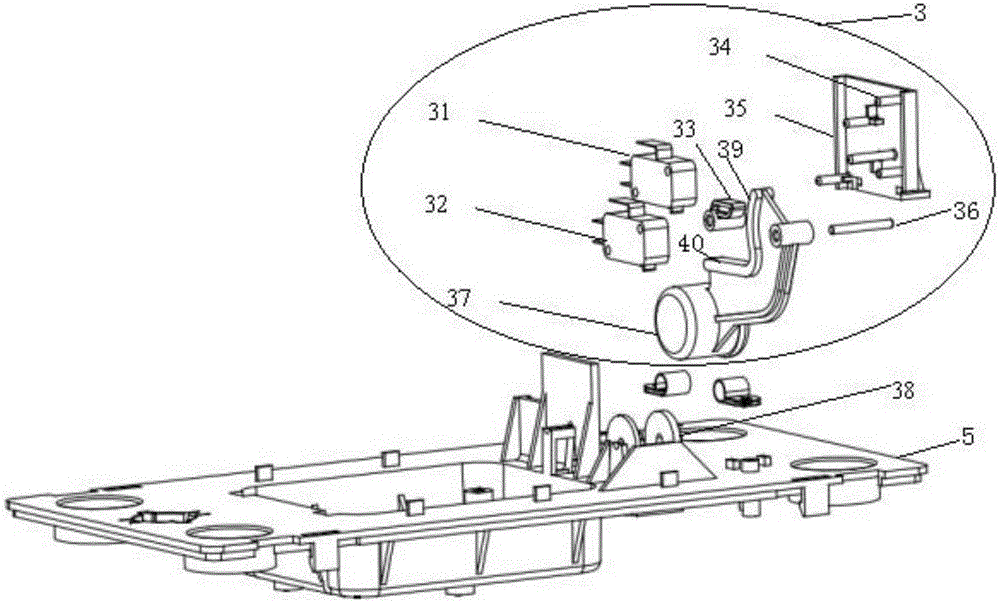

Condensation pump assembly

A condensate pump and assembly technology, applied in the field of condensate pump control system, can solve problems such as stuck, burned micro switch, easy to generate large current, etc., and achieve the effect of controlling the movement of the floating ball, loose requirements, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Through extensive and in-depth research, the inventor accidentally invented a new type of condensate pump assembly for the first time. The control system of single float and toggle button designed by anti-self-locking principle can ensure smooth triggering of two micro switches . The present invention has been accomplished on this basis.

[0049] Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

[0050] In the description of the present invention, in order to clearly demonstrate the structure and working method of the present invention, many directional words will be used for description, but "front", "rear", "left", "right", "outer" should be used , "inward", "inward", "outward" and other words are understood as convenient terms, and should not be understood as limiting words, which are only for the convenience of describing the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com