Feeding mechanism and and bagging machine with same

A feeding mechanism and material bag technology, which is applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problem of repeated pages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

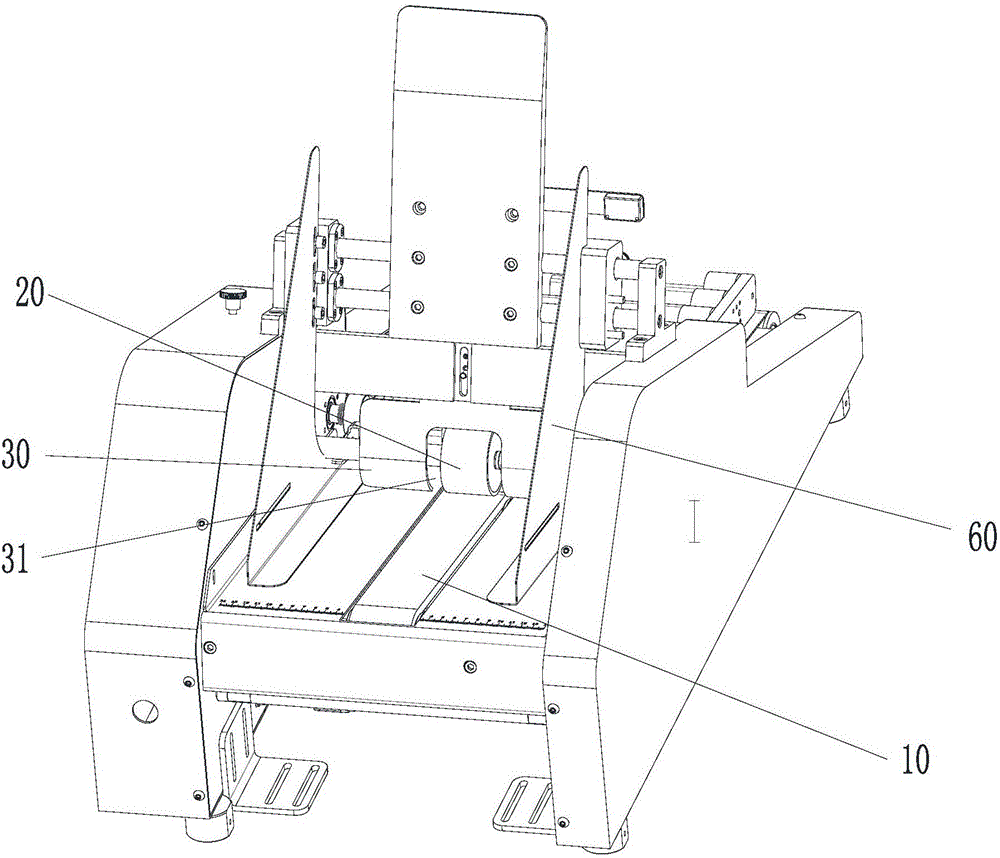

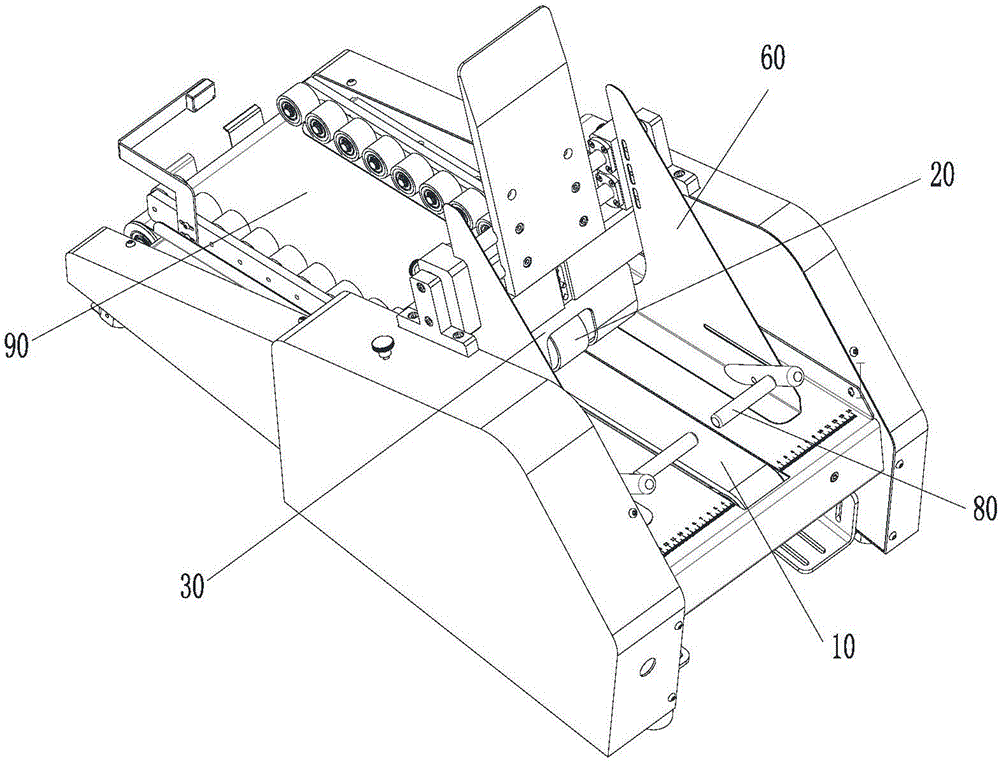

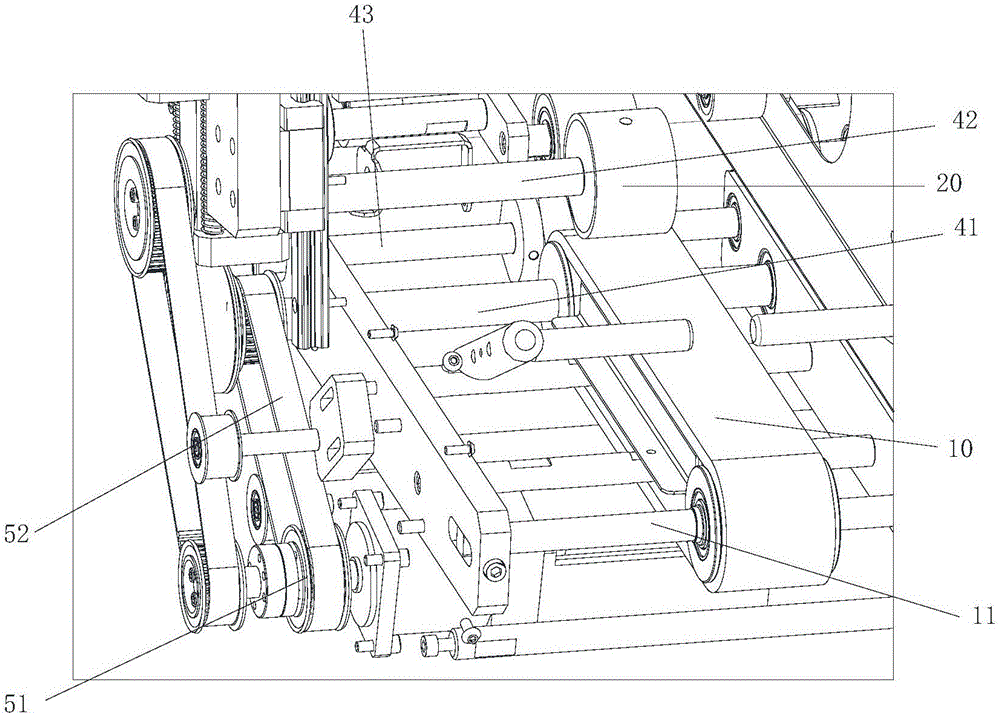

[0024] The present invention provides a feeding mechanism, please refer to Figure 1 to Figure 4 , including: a friction belt 10, a plurality of papers to be fed or a plurality of charging bags are stacked on the friction belt 10 and move with the friction belt 10; a pressing wheel 20, the pressing wheel 20 is rotatably arranged on the friction belt 10, between the friction belt 10 and the pinch wheel 20, there is a feeding gap for a single paper or a single charging bag to pass through; the discharge belt 90 is rotatably arranged on the pinch wheel 20 The discharge side is to transmit the paper or the charging bag from the pressing wheel 20; the accelerating assembly 70, the accelerating asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com