Automatic pole climbing device and electric maintenance vehicle

A pole-climbing and automatic technology, applied in the direction of lifting device, switch device, electrical components, etc., can solve the problems of complicated operation, pole slippage, poor safety, etc., and achieve the effect of high safety, stable pole-climbing process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

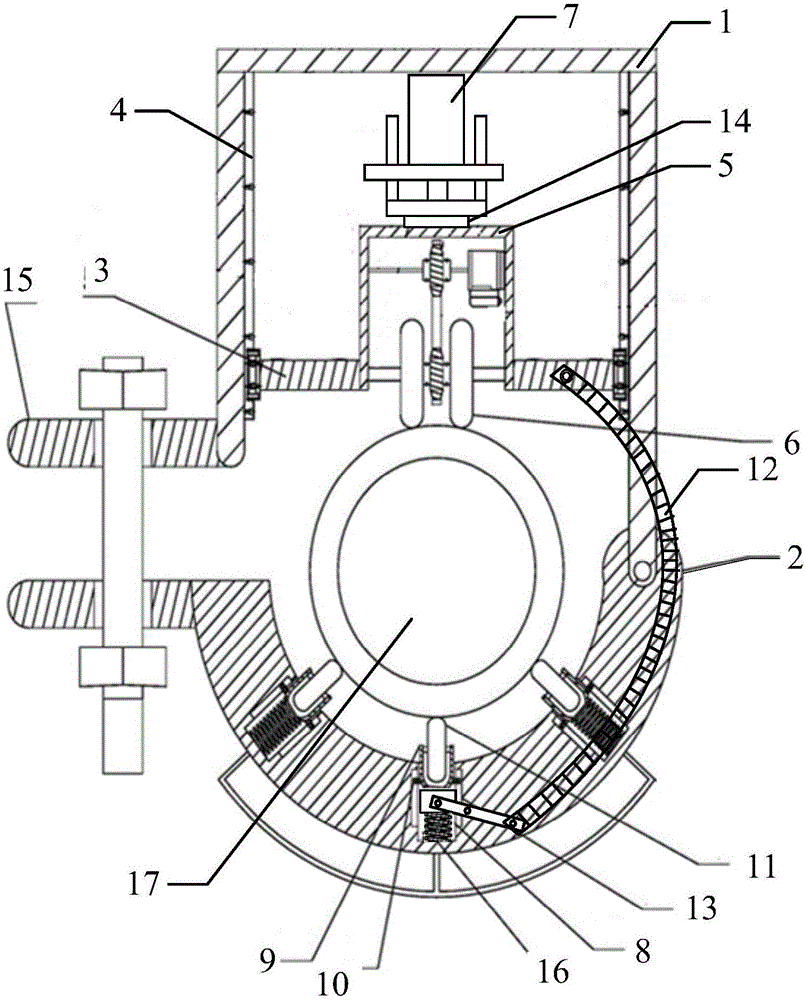

[0032] Embodiment 1 of the present invention provides an automatic pole climbing device, such as figure 1 The schematic diagram of the structure of the automatic pole climbing device is shown, the automatic pole climbing device includes a working platform (not shown), a first frame 1 and a second frame 2, and the working platform is fixed on the first frame 1.

[0033] Specifically, the first frame 1 and the second frame 2 are oppositely arranged, wherein one end of the first frame 1 is hinged to one end of the second frame 2, and the ends of the first frame 1 and the second frame 2 away from the hinge are respectively provided with clamping plates 15. The clamping plates 15 are provided with first through holes, and the first through holes fix the first frame 1 and the second frame 2 through bolts. In use, the pole 17 is clamped between the first frame 1 and the second frame 2 .

[0034] The first frame 1 includes a support assembly 3, which can slide along the guide rails 4...

Embodiment 2

[0063] Embodiment 2 of the present invention provides an electric maintenance vehicle, including the automatic pole climbing device provided in the above embodiment,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com