Touch display device, pressure sensing unit and manufacturing method of pressure sensing unit

A technology of sensing unit and touch sensing, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc., can solve the problems of inaccurate reflection of changes in pressure and low sensitivity of pressure sensing, and achieve multi-point Pressure recognition and positioning, and the effect of improving pressure response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

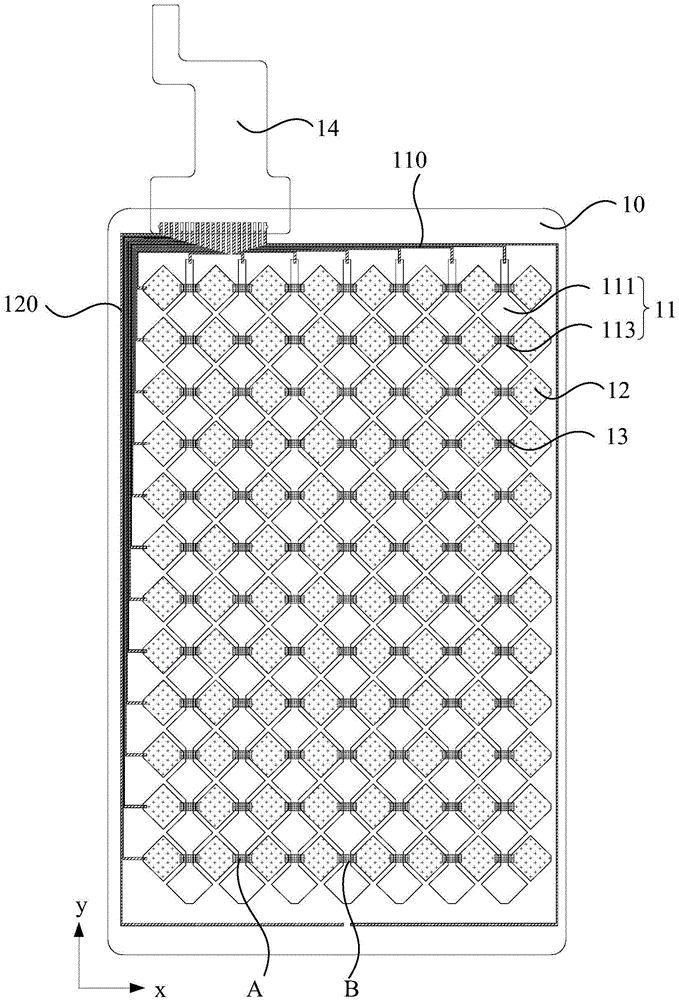

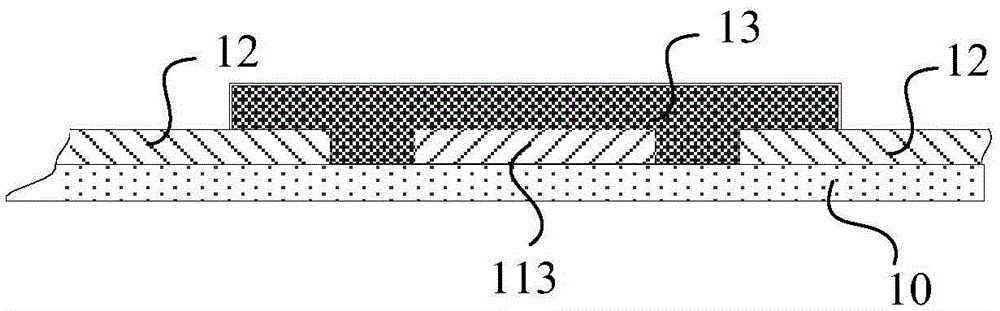

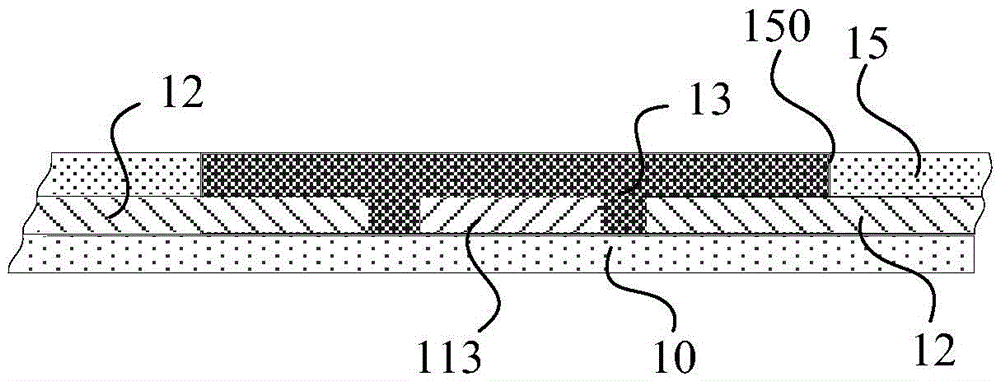

[0027] The touch display device provided by the present invention can be used as a display terminal with a touch interaction form such as a mobile phone and a tablet computer.

[0028] The touch display device includes a protective cover, a touch sensing unit, a pressure sensing unit and a display unit.

[0029] The protective cover can be a strengthened glass cover, a plastic cover, a polymethyl methacrylate (PMMA) cover or the like.

[0030] The touch sensing unit includes touch driving electrodes and touch sensing electrodes. The touch driving electrodes and the touch sensing electrodes can be distributed on the same substrate, such as the so-called GF structure, GF2 structure, etc. in the industry, or respectively distributed on two different substrates, such as the GFF structure called in the industry. In some other embodiments, the touch driving electrodes and the touch sensing electrodes may also be formed on the lower surface of the protective cover so that the protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com