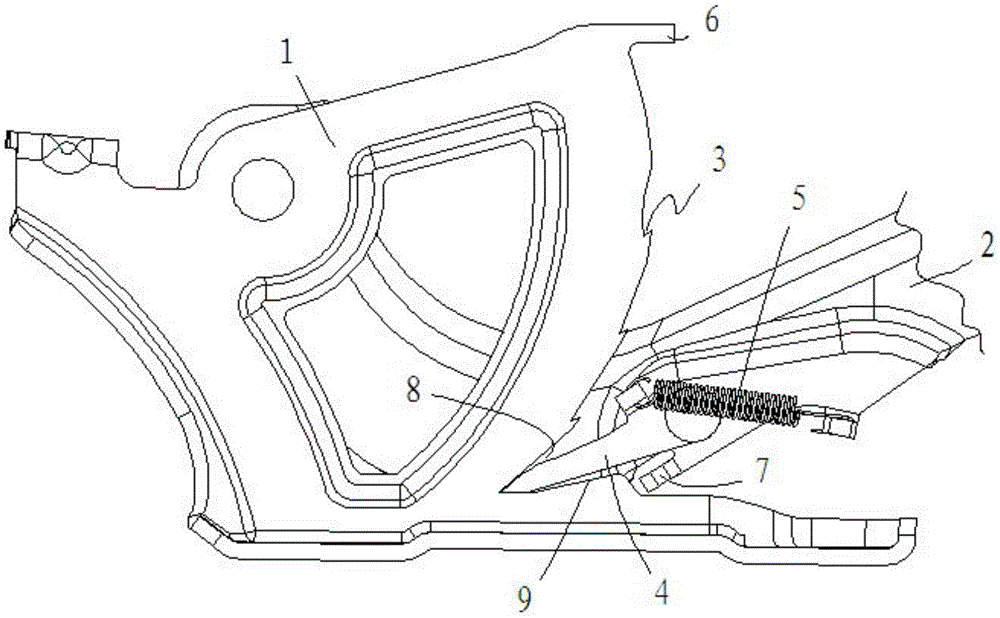

Engine hood connection supporting mechanism and vehicle

A technology of engine cover and supporting mechanism, which is applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., which can solve the problems of occupying the space of the engine compartment, increasing the mass of the whole vehicle, unfavorable design of the space of the engine compartment, and the lightweight design of the whole vehicle. , to achieve the effect of improving practicability and facilitating support operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] This embodiment relates to an automobile, which includes a vehicle body with an engine cover, and the engine cover is arranged on the vehicle body through the engine cover connection support mechanism as described in the first embodiment. In this automobile, the engine cover is connected to the vehicle body through the engine cover connection support mechanism as in Embodiment 1, which can avoid designing the existing support rod structure for engine cover support on the vehicle body and reduce the space design of the engine compartment and the light weight of the whole vehicle. Quantify the impact of the design, and through the engine hood connection support mechanism in the first embodiment, automatic support can also be realized when the engine hood is opened, and the automatic release of the support can be realized when the engine hood is closed, so that it also has a good practicality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com