Motor braking device

A technology of brake devices and brake pads, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., and can solve problems such as inability to release the brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described below in conjunction with the accompanying drawings.

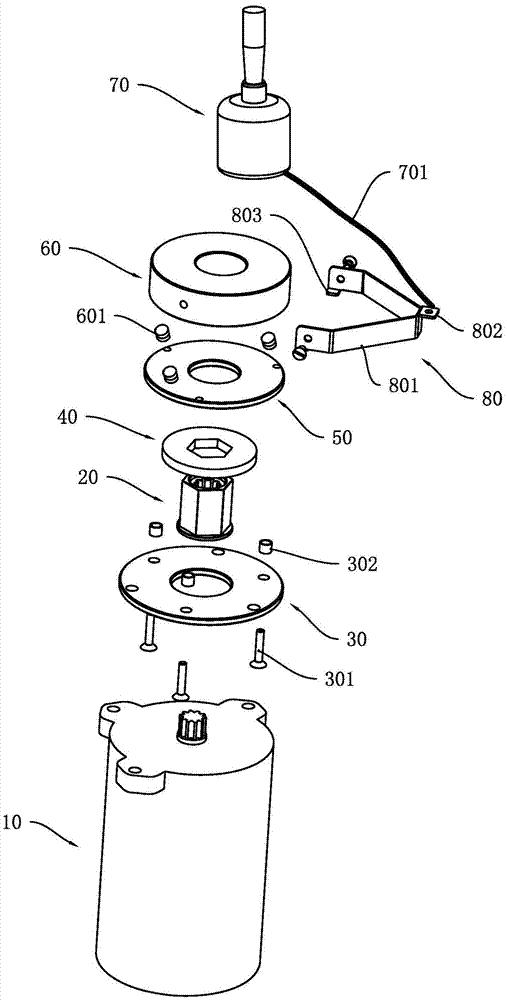

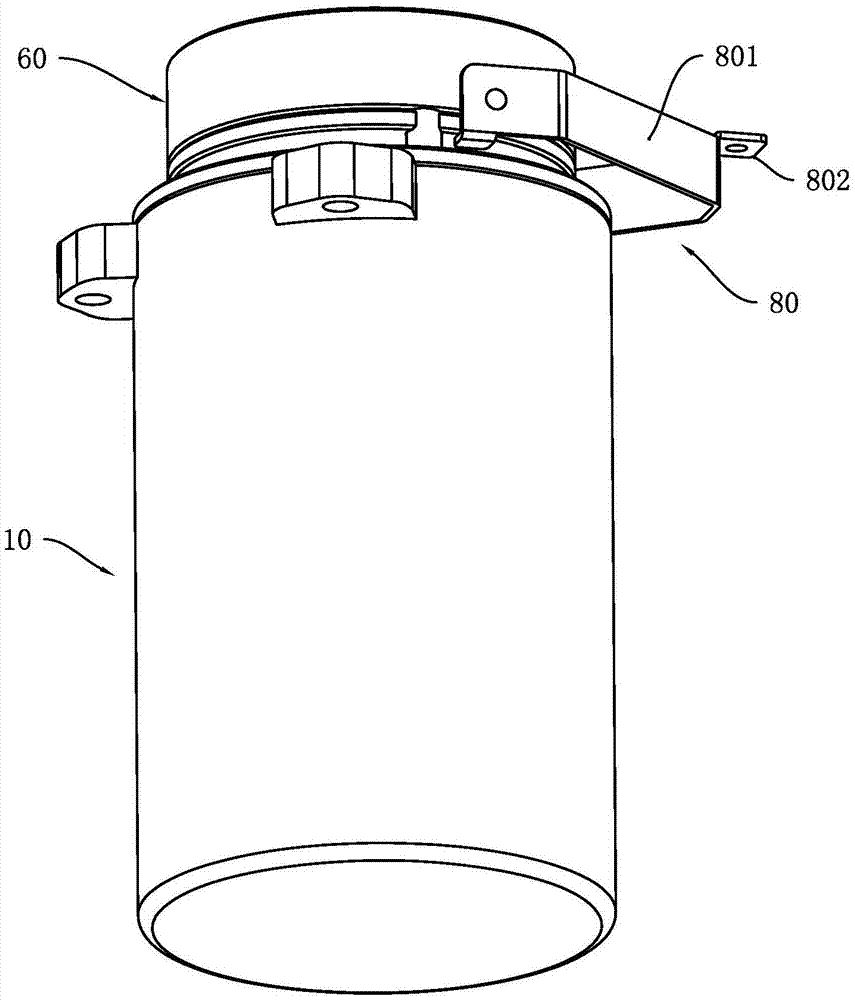

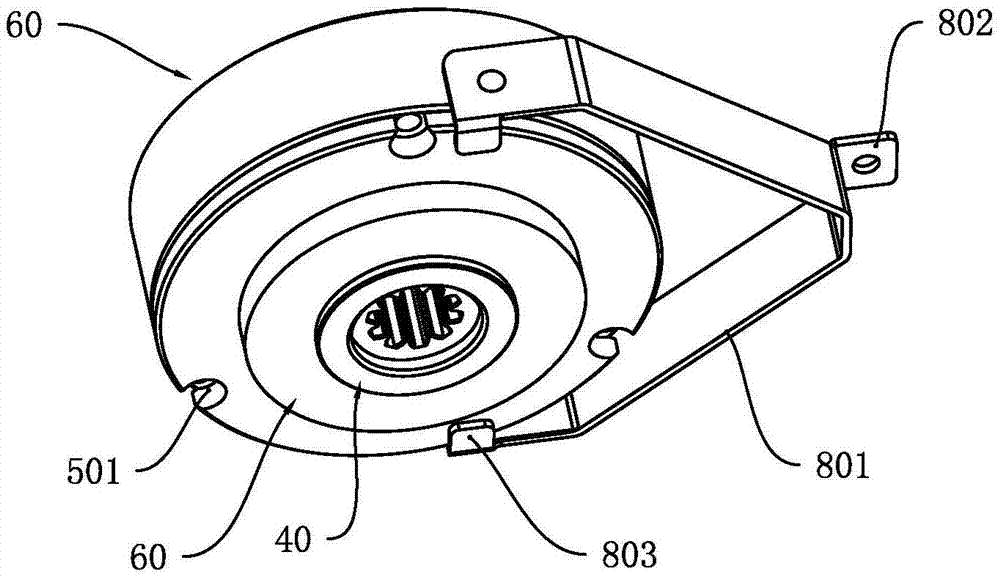

[0018] Such as Figure 1 to Figure 4 As shown, a motor braking device includes a motor 10, a shaft coupling 20 around the main shaft of the motor 10, and the coupling 20 is sequentially covered with a bottom plate 30, a brake pad 40, and an armature block 50 from the direction close to the motor 10 to the direction away from the motor 10. and the electromagnet 60; and the brake pad 40 is interference fit with the coupling 20, the base plate 30, the armature block 50 and the electromagnet 60 are respectively in clearance fit with the coupling 20; the base plate 30 and the electromagnet 60 pass through the connecting rod 301 provided Fixed connection, the armature block 50 slides freely along the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com