Punching device for antenna reflecting surface

A punching device and reflective surface technology, applied in punching tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in punching inclined holes and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the punching device for the antenna reflective surface of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

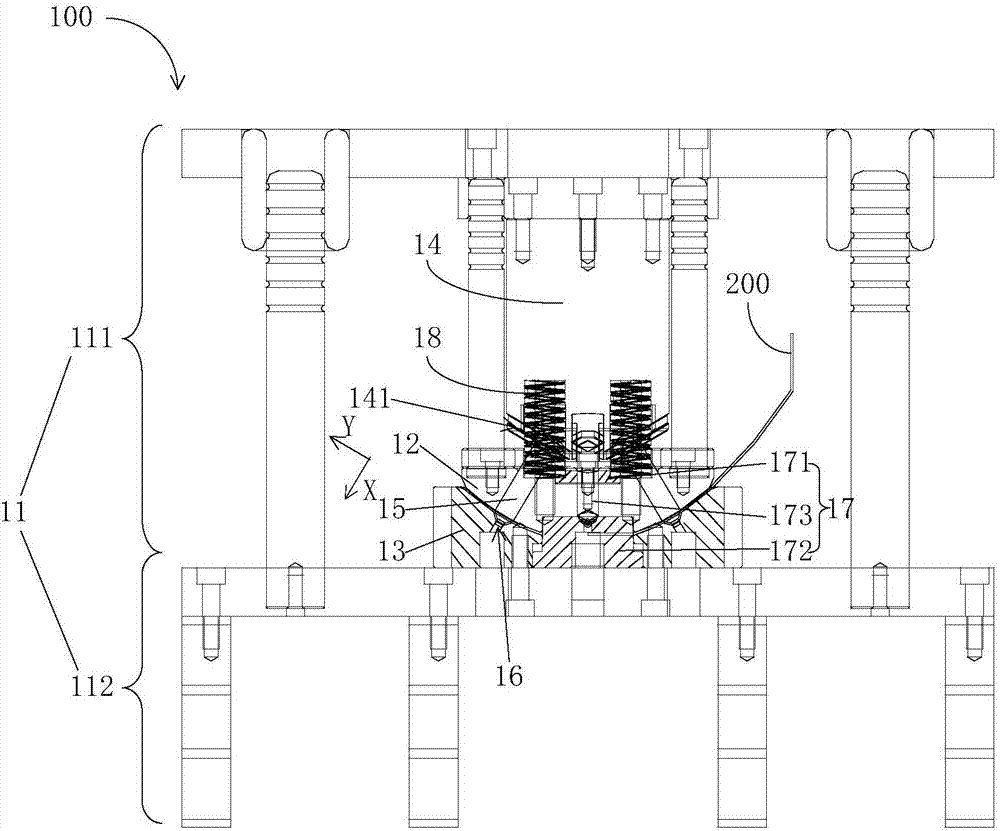

[0017] see figure 1 , figure 1 It is a structural diagram of an embodiment of the punching device for the antenna reflector of the present invention. The punching device 100 in this embodiment includes a bracket 11 , a punch 12 and a die 13 , a slider 14 and a punch 15 .

[0018] Wherein, described die 13 is arranged on the bottom 112 of support 11, and punch 12 is arranged on the top 111 of support 11 with respect to die 13, and the upper part 111 of support 11 and the lower part 112 are set movably, can be adjusted up and down, when pairing antenna When the reflective surface 200 is punched, the antenna reflective surface 200 can be installed between the male mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com