Electric control cabinet L-shaped steel member punching device

A punching device and a technology for steel components, applied in the field of L-shaped steel component punching devices for electric control cabinets, can solve problems such as low precision and low punching efficiency, increase efficiency and reduce the time for multiple punching , the effect of easy support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

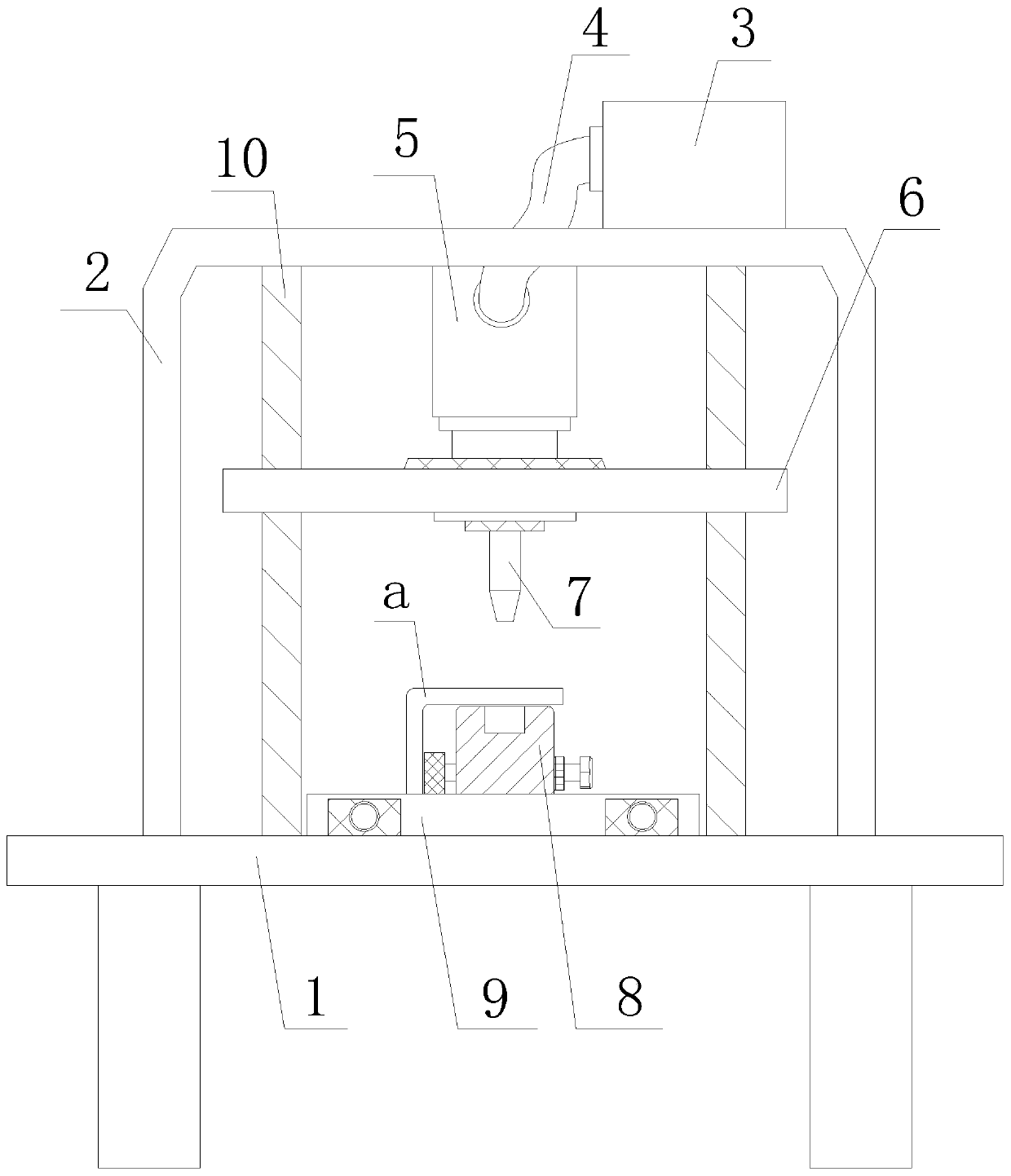

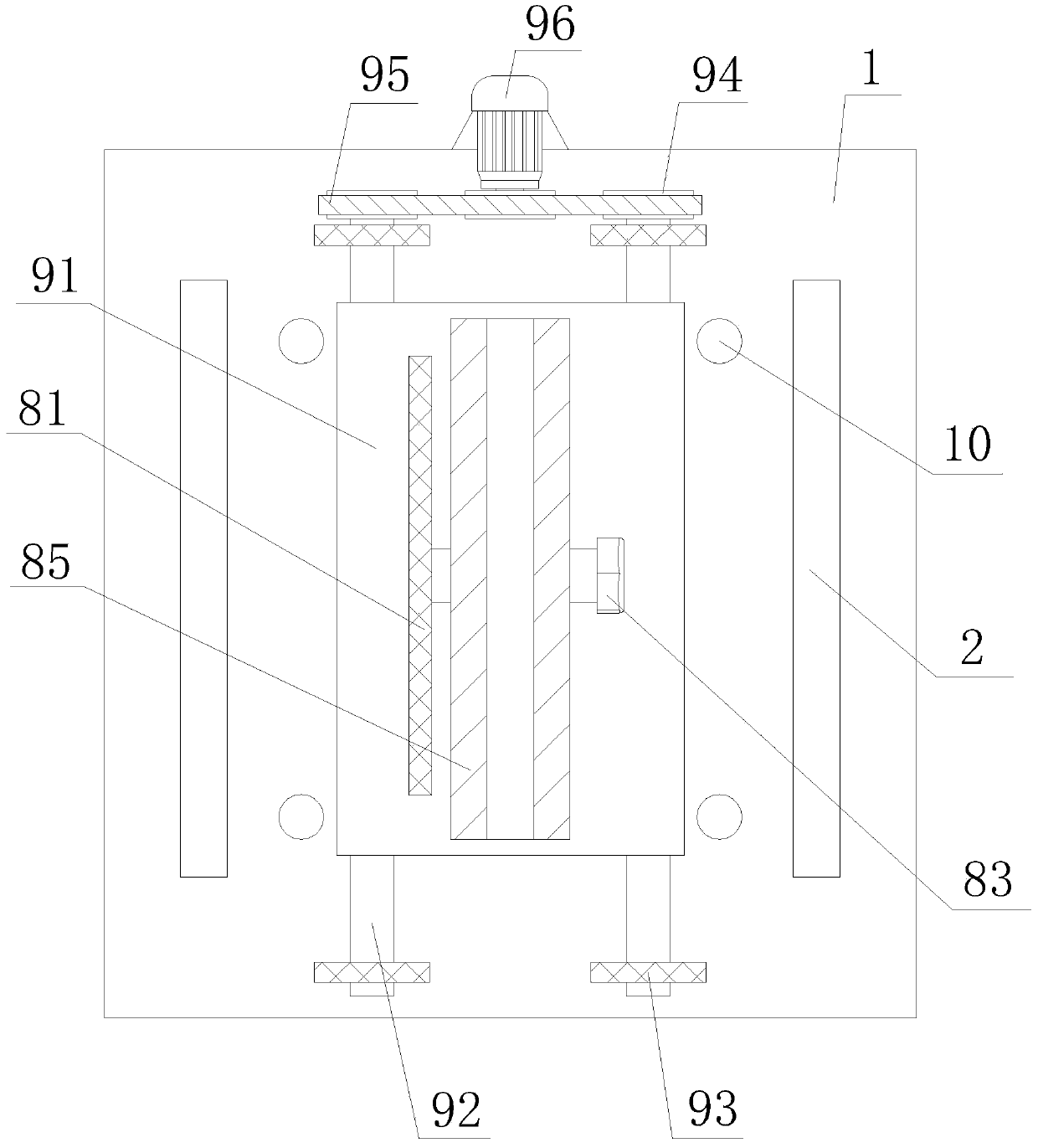

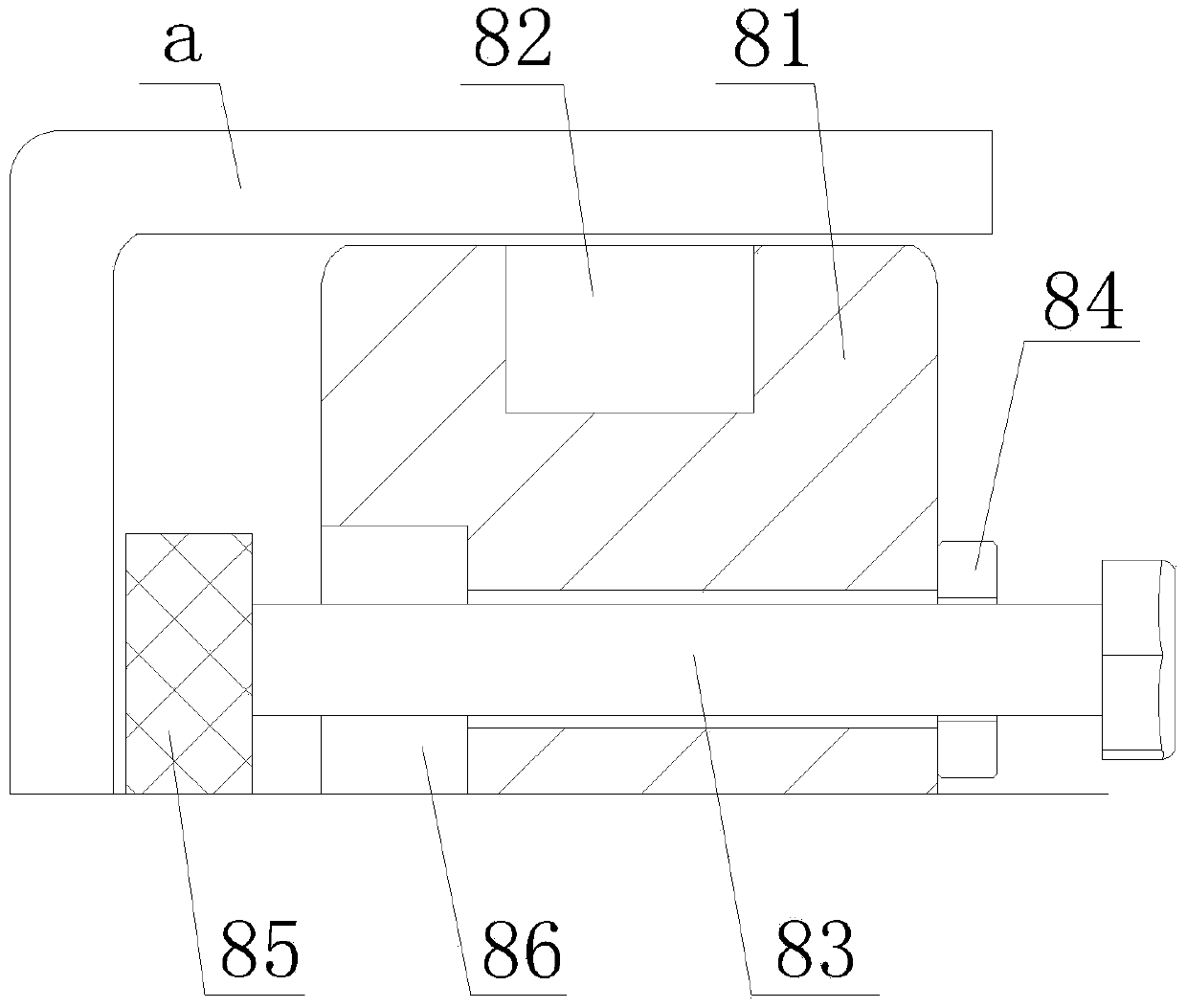

[0026] Attached below Figure 1-5 The present invention is further described with embodiment:

[0027] A punching device for an L-shaped steel member for an electric control cabinet, comprising a processing table 1, a plurality of supporting feet installed at the lower end of the processing table 1, and a frame 2 provided at the upper end of the processing table 1, the three form a stable whole, and the effective To ensure the installation of the punching device, a hydraulic station 3 is installed on the upper end of the frame 2, and the output end of the hydraulic station 3 is connected with two hydraulic rods 5 through the infusion tube 4, and the hydraulic rods 5 are fixedly installed on the machine. On the inner top wall of the frame 2, the same lifting plate 6 is installed on the output ends of the two hydraulic rods 5, and the lower end of the lifting plate 6 is detachably installed with a plurality of parallel punching heads 7 through the fixing seat. , the hydraulic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com