Tool box used for machining

A machining and tool box technology, applied in the field of tool boxes for machining, can solve the problems of difficult to find tools, no detailed classification, reduced machining efficiency, etc., to avoid center of gravity shift, simple structure, and eliminate rollover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

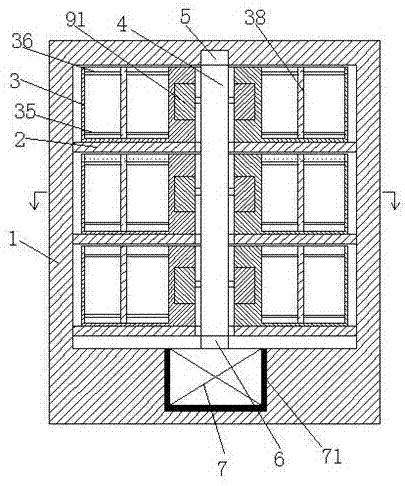

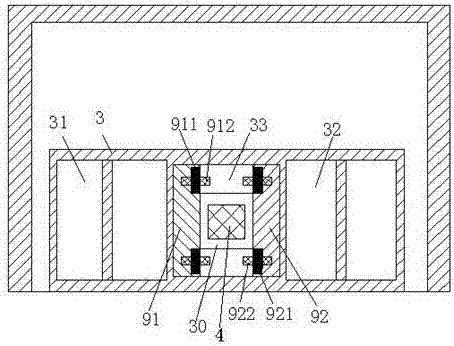

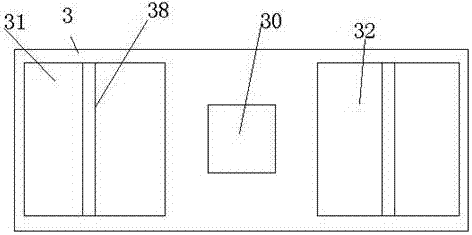

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3 , according to a tool box for machining according to the present invention, it includes a box body 1 and a plurality of laminates 2 fixedly installed in the box body 1 and spaced up and down, and the front part of each laminate 2 is rotatable A rotary box 3 for placing processing tools is installed, and the rotary box 3 and the left end wall, the right end wall and the rear end wall of the box body 1 leave a rotatable space, and the rotary box 3 includes left and right symmetrical settings. The left cutter groove 31 and the right cutter groove 31 and the chute 33 between the left cutter groove 31 and the right cutter groove 31, the center of the chute 33 and the front end of the support plate 2 are provided with a through hole 30 A left clamping block 91 and a right clamping block 92 are installed symmetrically in the chute 33, a left coil 911 is installed symmet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap