A hanging tag automatic rope threading machine

An automatic threading and tagging technology, which is applied to labeling machines, packaging, marking deformable materials, etc., can solve the problem of low efficiency of threading tags, and achieve the effect of accurate and high-efficiency threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

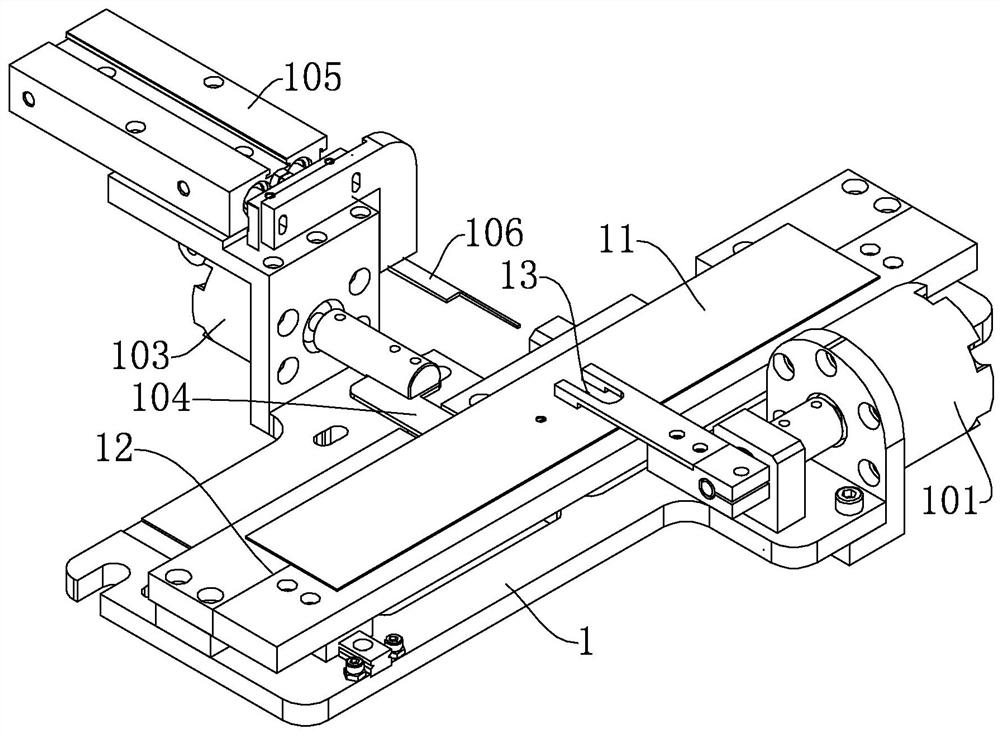

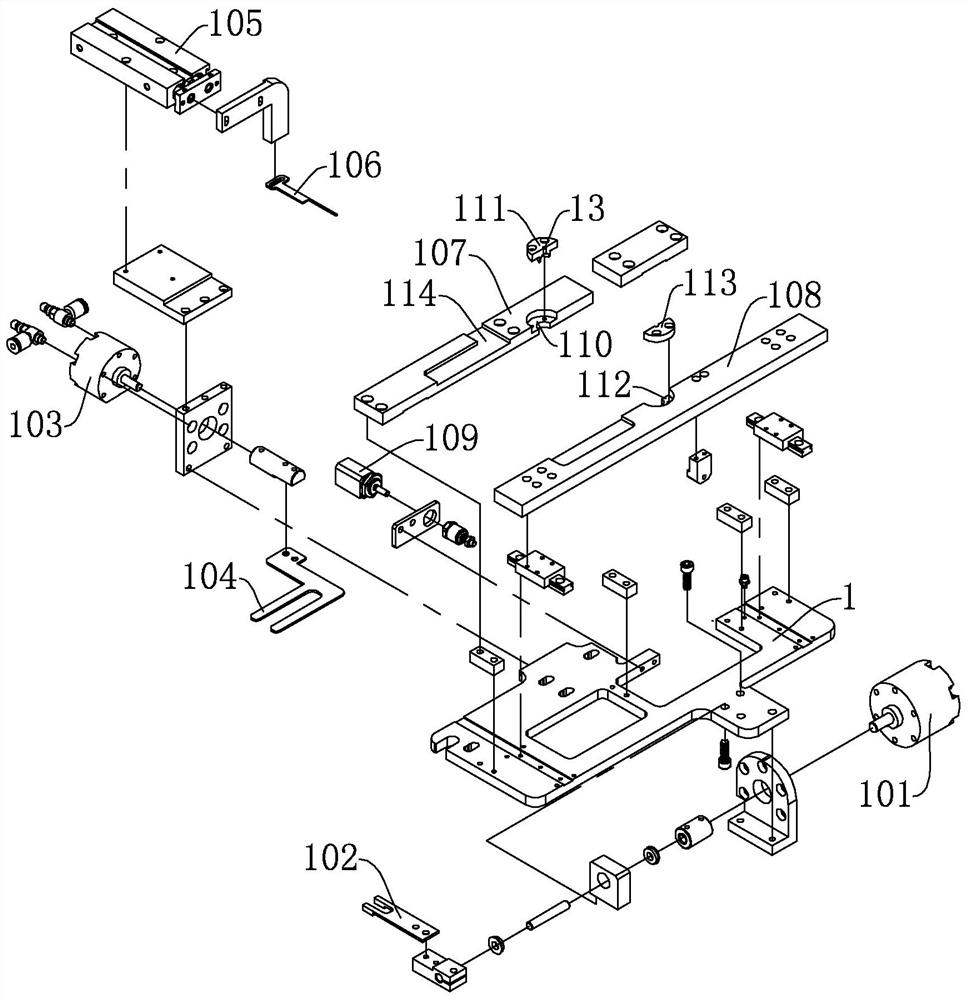

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

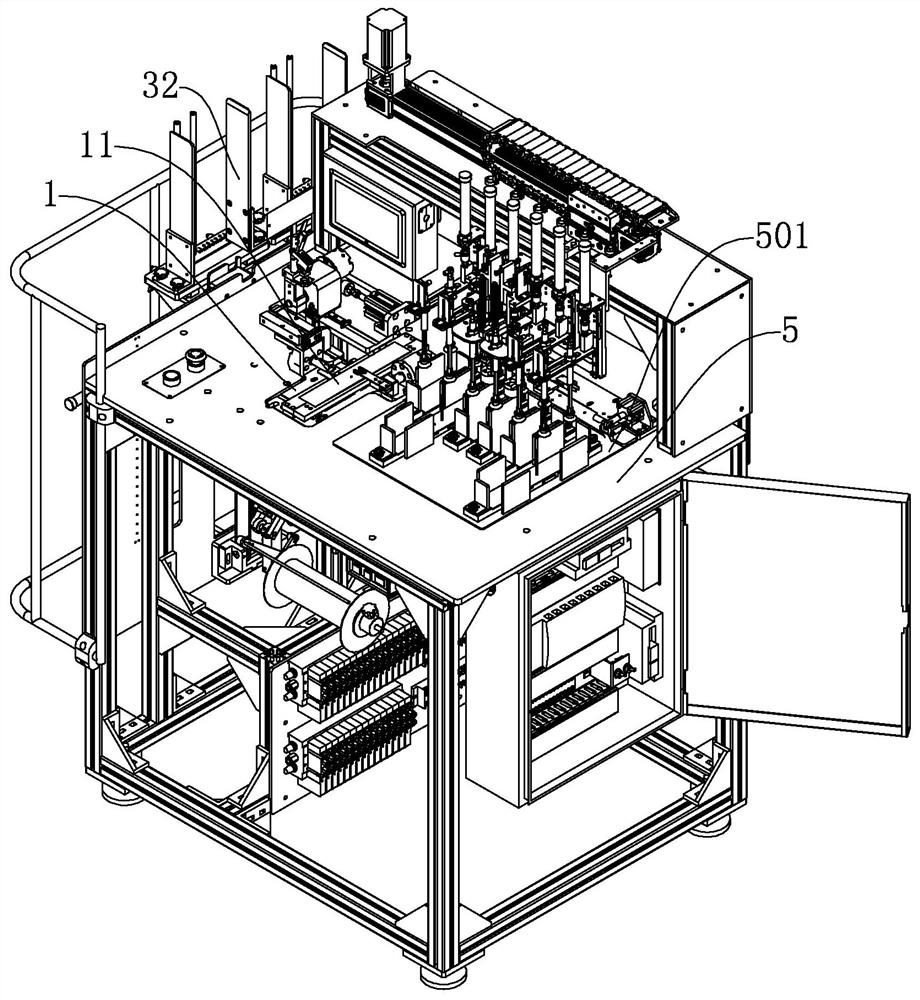

[0032] Figure 1 to Figure 15 Shown is the structural representation of the present invention.

[0033] Wherein the reference numerals are: folding installation bottom plate 1, the first rotary cylinder 101, the first pressing plate 102, the second rotating cylinder 103, the second folding plate 104, the third cylinder 105, the third pressing rod 106, the first A fixed plate 107, a second fixed plate 108, a control cylinder 109, a hanging tag 11, a first semicircular groove 110, a first rope threading block 111, a second semicircular groove 112, a second rope threading block 113, and the first groove 114, fixed plate 12, threading hole 13, threading rod mount 2, first vertical groove 201, rope threading rod 202, fork rope opening 203, rope pushing block 204, second vertical groove 205, lift Guide rail 206, first cylinder 207, second cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com