A paint preparation device

A pigment and mounting seat technology, applied in the field of art utensils, can solve the problems of inability to prepare multiple color pigments at one time, inability to realize mixing and stirring of pigments, etc., and achieve the effect of saving manpower and convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

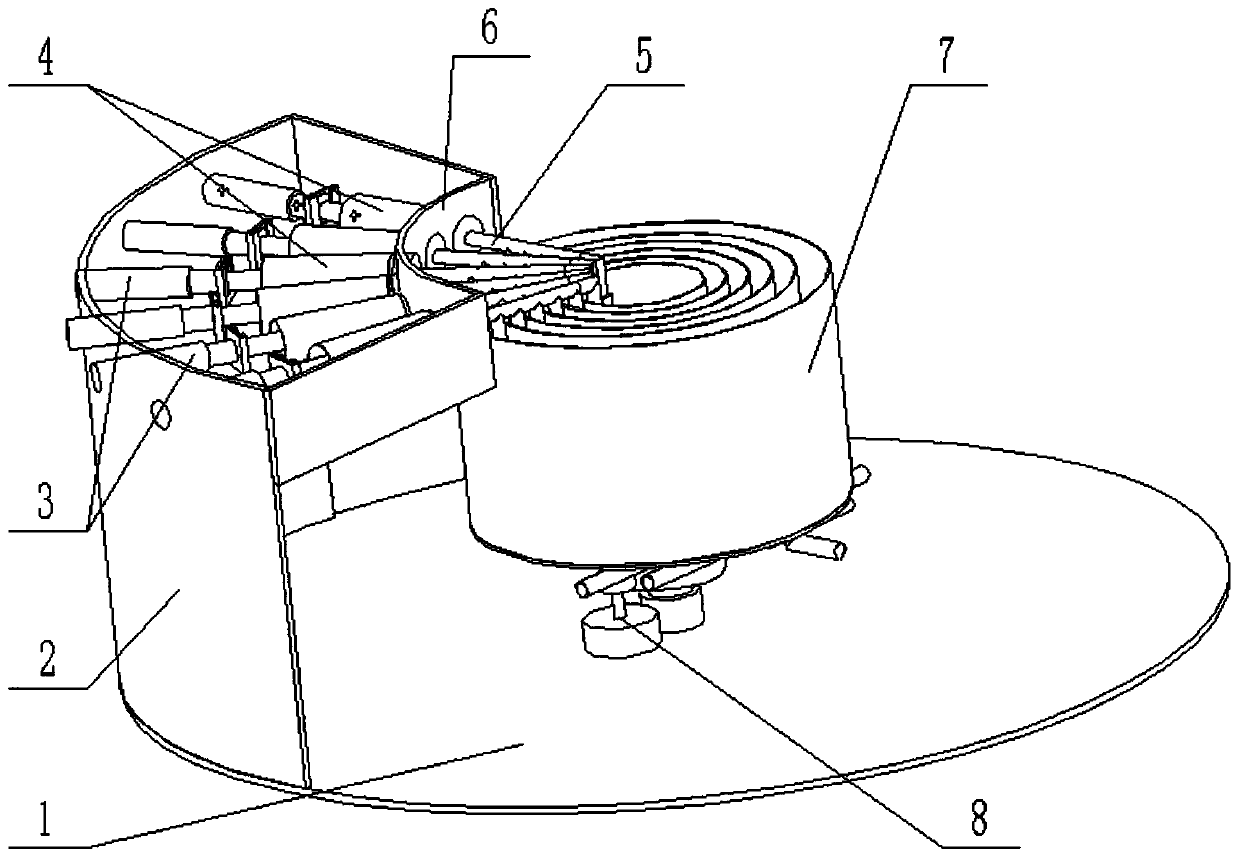

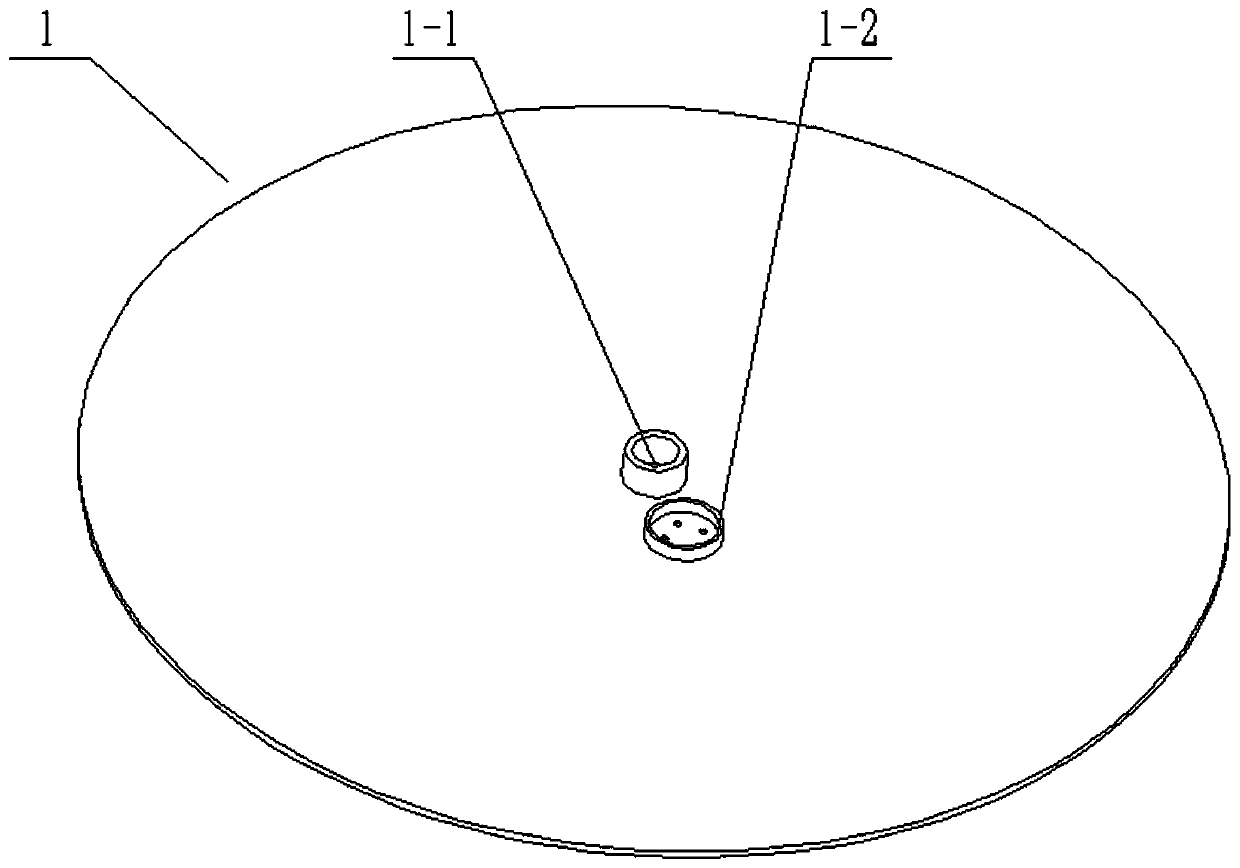

[0045] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, a pigment preparation device, including a base plate 1, a first support plate 2, a plurality of extruding devices 3, a plurality of A paint bucket 4, a drainage device 5, a second support plate 6, a modulation box 7, and a speed-reducing driving device 8 are characterized in that: the base plate 1 is in a circular structure, and the center of the upper end surface of the base plate 1 is provided with a bottom end Shaft seat 1-1, the bottom end shaft seat 1-1 is a circular structure with a blind hole in the center of the circle, the upper end surface of the base plate 1, the bottom end shaft seat 1-1 is provided with a drive motor seat 1-2, and the drive motor The seat 1-2 is an annular boss, and the bottom surface of the drive motor seat 1-2 is provided with a threaded hole;

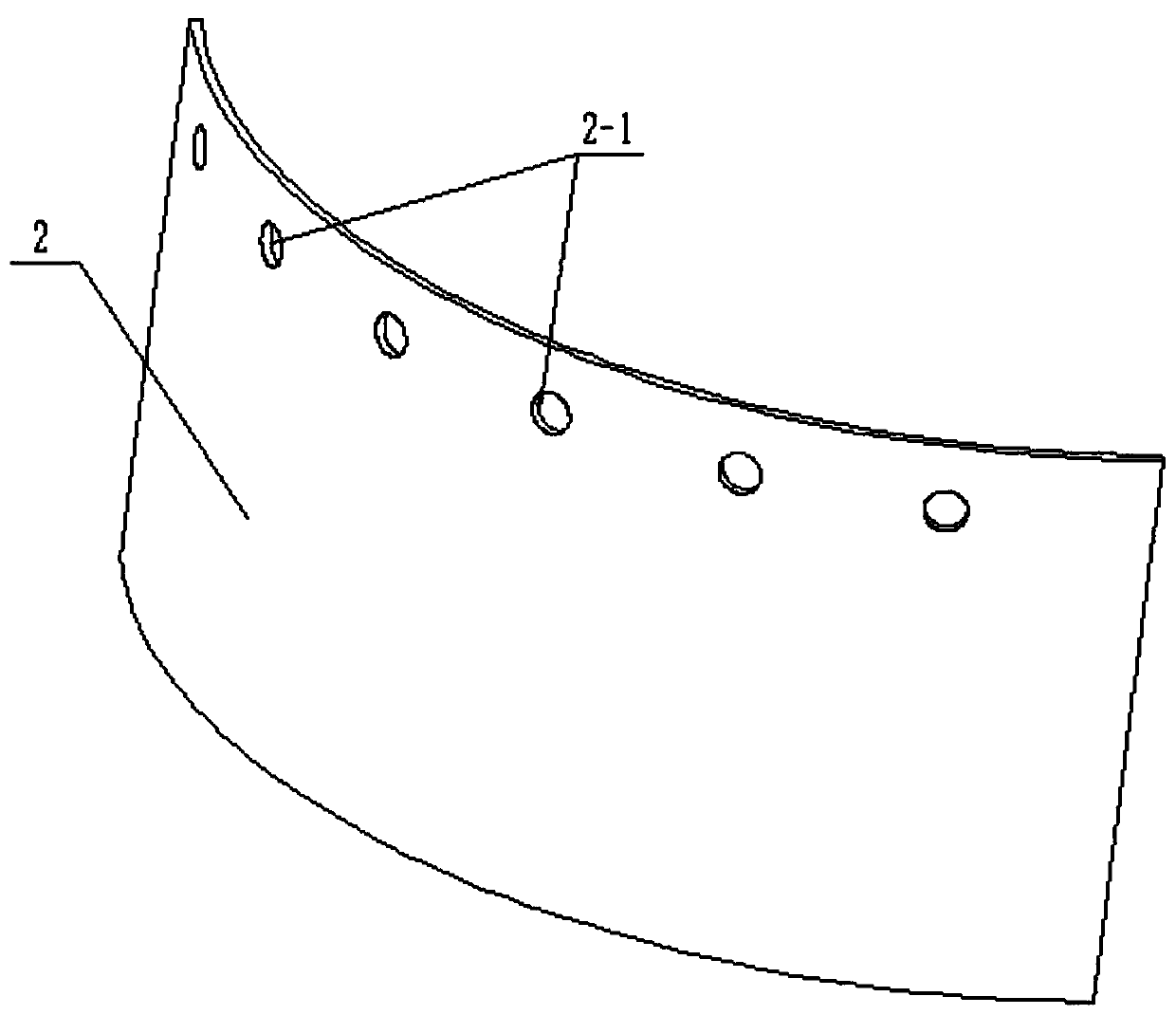

[0046] The first support plate 2 is an arc-shaped structure, and the upper end of the side wall of the fi...

specific Embodiment approach 2

[0055] Combine below figure 1 , 2 . The clamping groove 3-4 of the material device 3 is a clearance fit, and the liquid outlet pipe 4-5 of the paint bucket 4 and the drainage socket 5-2 of the drainage device 5 are an interference fit.

specific Embodiment approach 3

[0057] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, and this embodiment will further describe Embodiment 1, and the upper ends of the plurality of vertical drainage tubes 5-4 are all set There are normally closed solenoid valves, and a plurality of normally closed solenoid valves with longitudinal drainage tubes 5-4 are connected in parallel; the drive motor 8-1 of the deceleration drive device 8 is connected in parallel at two stages of power supply; the multiple The normally closed solenoid valve at the upper end of the vertical drainage pipe 5-4 can be a normally closed solenoid valve of model HOPE81; the model of the control valve connected to the L-shaped liquid outlet pipe 7-4 is Q41F-10S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com