Double-color mold sliding block core-pulling delay mechanism and operating method thereof

A slider core-pulling and two-color mold technology, applied to other household appliances, household appliances, household components, etc., can solve problems such as sticky sliders, poor toughness, and large mold release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

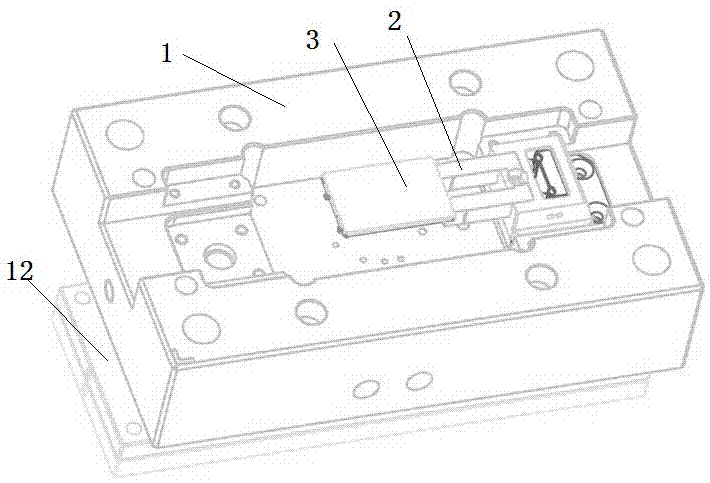

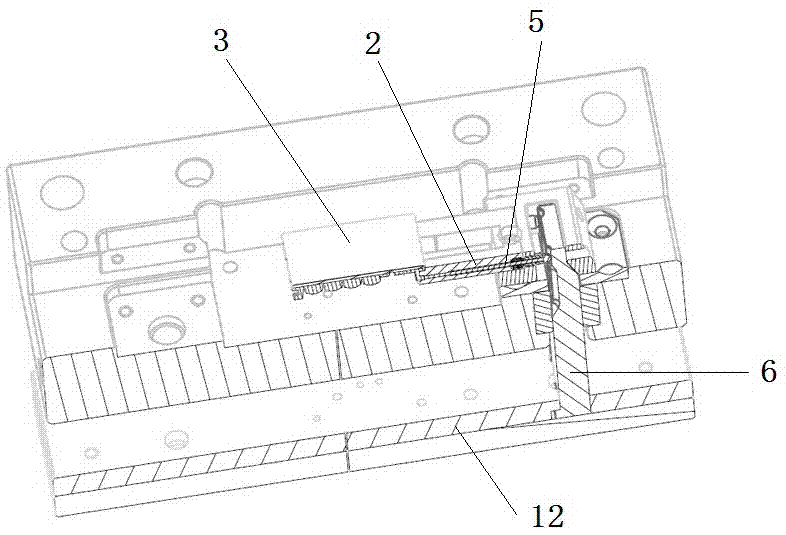

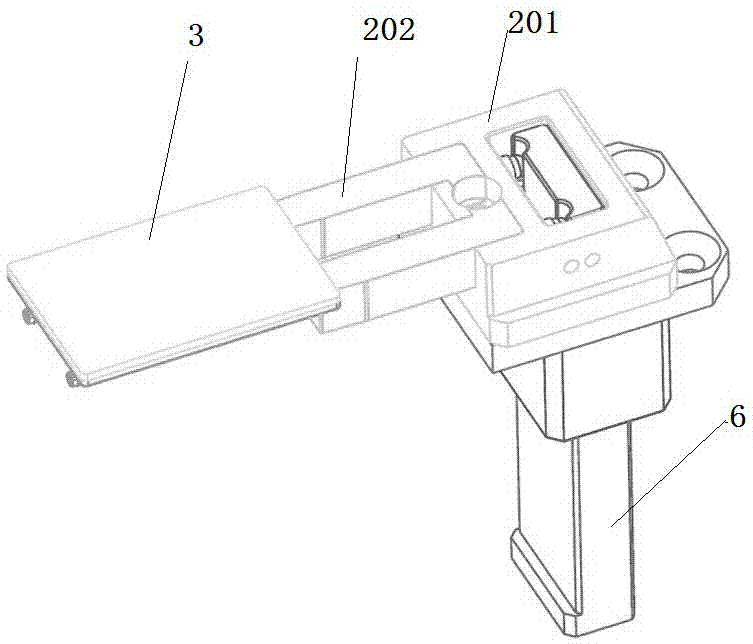

[0026] The core-pulling delay mechanism of the two-color mold slider of the present invention includes a two-color mold 1 and a sliding sleeve 2 arranged on the two-color mold for being set on the entire periphery of the outer convex column of the finished product. 3 The stop post 5 on the outer end surface of the outer convex post 4, a liftable top block 6 is provided between the bottom of the stop post 5 and the bottom of the sliding sleeve 2, and two ends are provided on the end surface of the top block near the side of the sliding sleeve. Platform surface 7, transition 8 by inclined plane between two platform surfaces; On the end face of described top block 6 near stop post 5 side, be provided with track g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com