An intelligent pumping unit operating condition test device

A testing device and pumping unit technology, which is applied to measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of not being able to test the load of the wire rope in the whole process, not being able to enter the oil pipe, and not being able to test the displacement at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

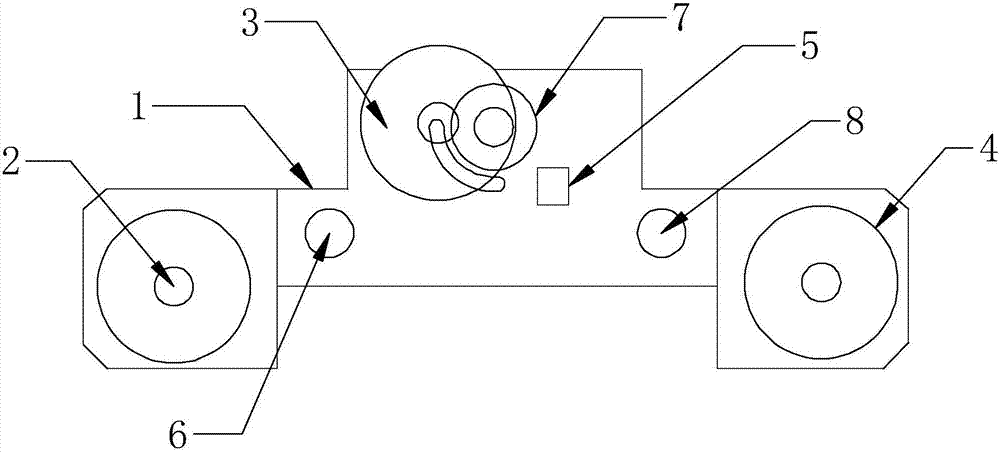

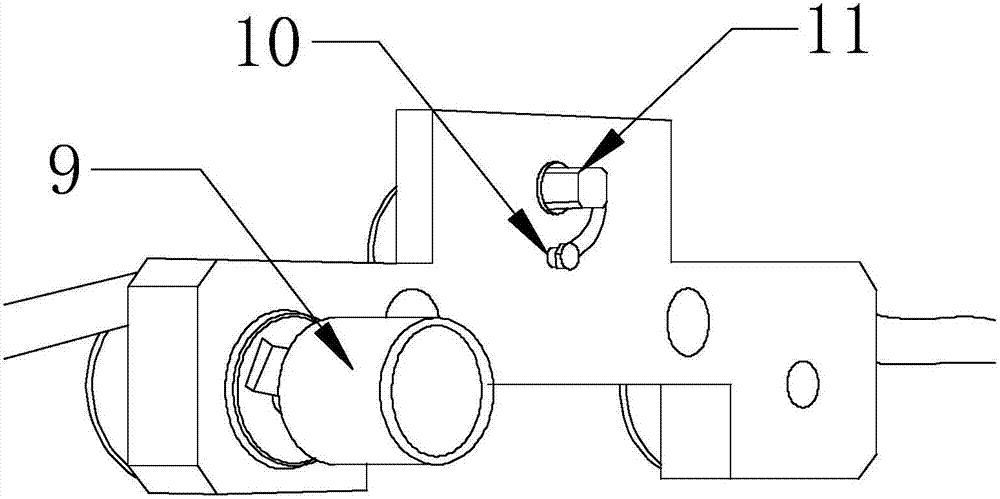

[0014] The working condition test device of the intelligent pumping unit in the embodiment of the present invention, in figure 1 Among them, the fixed shaft pulley 2, the deflection pulley 3, and the counting pulley 4 are fixed on the body 1 in a triangular distribution, and the deflection pulley 3 can rotate 90 degrees around the deflection axis 7, and thrust against the thrust block 5 when it deflects downward. Test The front deflection pulley 3 deflects 90 degrees upwards, so that the wire rope passes through without unloading. The strain gauges 6 are symmetrically distributed on the sensor body and are used to calculate the load.

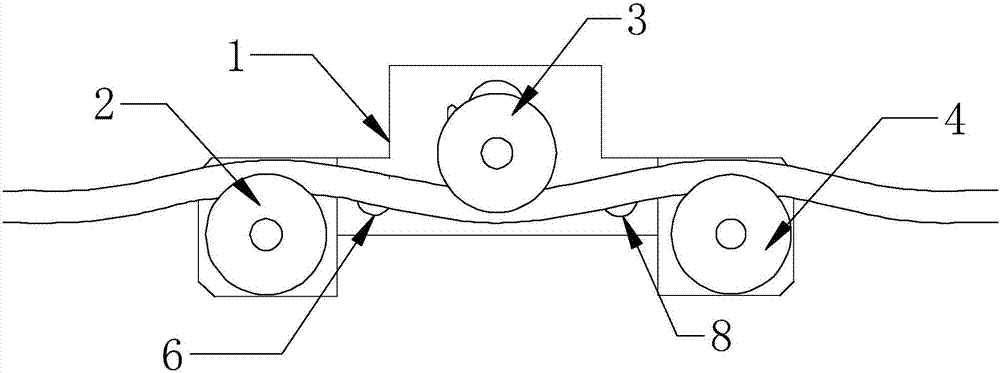

[0015] exist figure 2 In the shown embodiment, the test device is in the test state, the deflection pulley 3 deflects downward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com