A gasification furnace cooling protection device

A technology of cooling device and gasifier, which is applied in the field of gasifier to achieve the effects of ensuring long-term operation, preventing high temperature burn-through, and avoiding stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

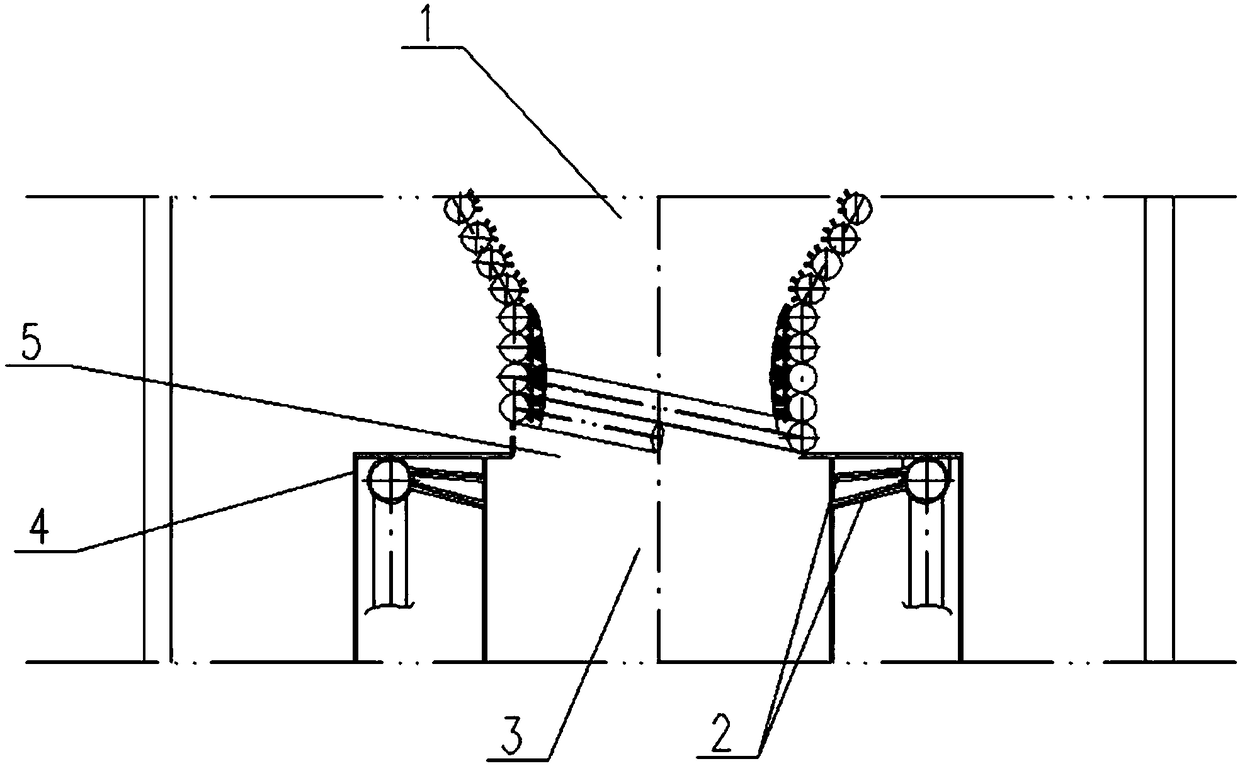

[0041] A cooling protection device for a gasification furnace, comprising: a cooling device, which is arranged at the connecting section between the lower slag port of the gasification chamber of the gasification furnace and the quenching device.

Embodiment 2

[0043] A cooling protection device for a gasification furnace, comprising: a cooling device, which is arranged at the connecting section between the lower slag port of the gasification chamber of the gasification furnace and the quenching device.

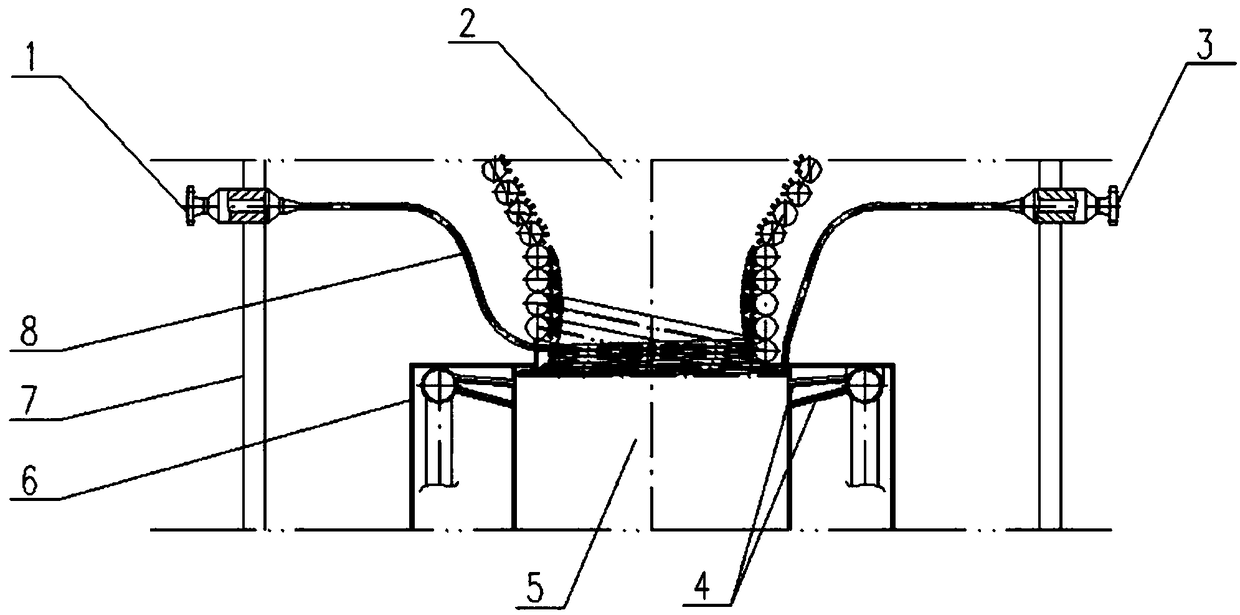

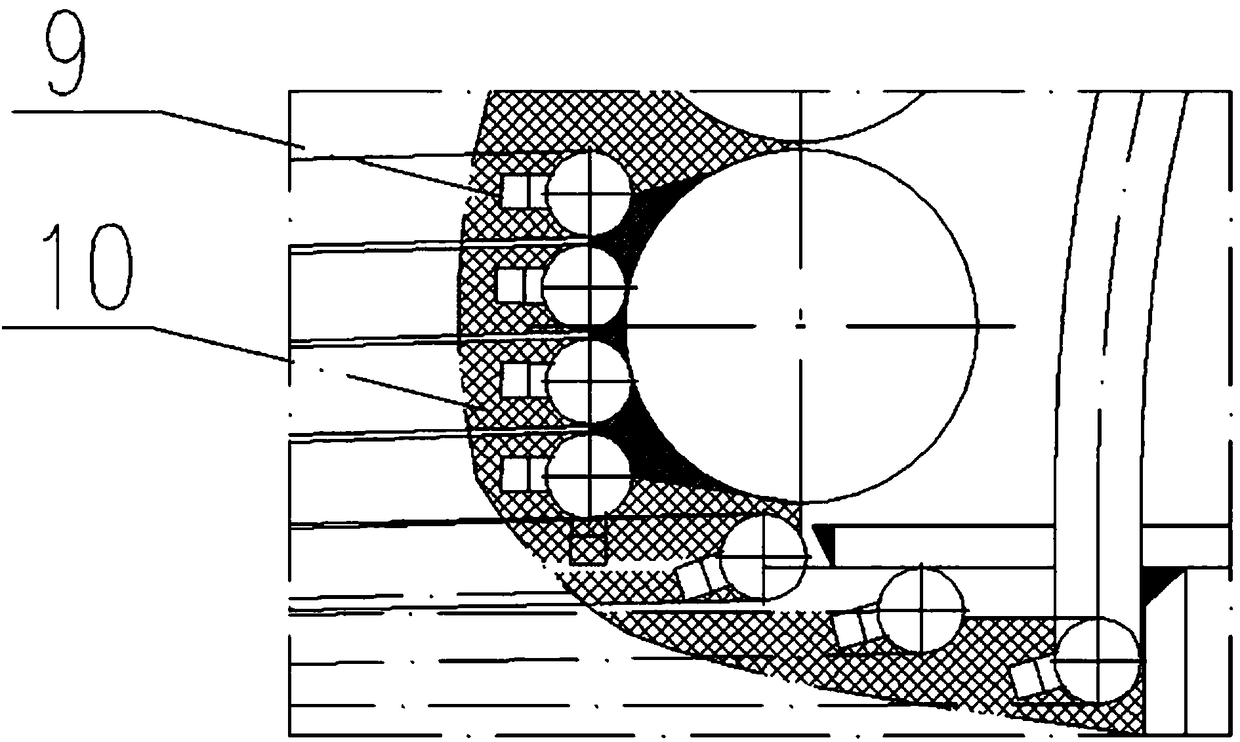

[0044] The cooling device includes: a water inlet pipe, a cooling coil, an outlet pipe, and a curved expansion bend; the cooling coil surrounds the outside of the connecting section between the lower slag port of the gasification chamber and the quenching device, and the cooling coil The inlet and outlet are respectively connected with the water inlet pipe and the water outlet pipe, and the inner section of the inlet and outlet of the cooling coil is provided with a curved expansion bend.

Embodiment 3

[0046] A cooling protection device for a gasification furnace, comprising: a cooling device, which is arranged at the connecting section between the lower slag port of the gasification chamber of the gasification furnace and the quenching device.

[0047] The cooling device includes: a water inlet pipe, a cooling coil, an outlet pipe, and a curved expansion bend; the cooling coil surrounds the inside of the connecting section between the lower slag port of the gasification chamber and the quenching device, and the cooling coil The inlet and outlet are respectively connected with the water inlet pipe and the water outlet pipe, and the inner section of the inlet and outlet of the cooling coil is provided with a curved expansion bend.

[0048] The bending expansion bend is set according to the requirement of expansion displacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com