Reflector device for road

A reflective mirror and road technology, applied in the field of road reflective mirrors, can solve the problems of increased difficulty of road reflective mirrors, cumbersome and laborious operation process, inconvenient adjustment and installation, etc., and achieve the effects of reducing equipment complexity, increasing installation speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

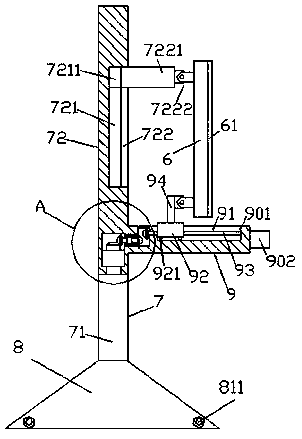

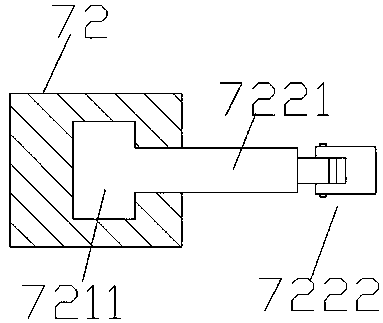

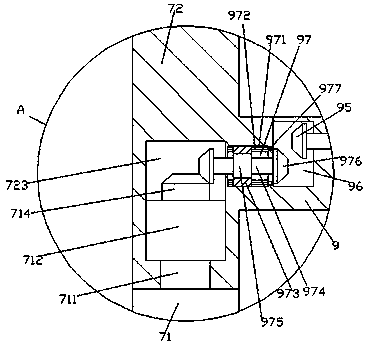

[0018] Such as Figure 1-Figure 4 As shown, a road reflector device of the present invention includes a vertical rod 7 connected by an upper straight rod 72 and a lower straight rod 71 and a control part 9 fixedly connected to the upper straight rod 72. The inner bottom of the rod 72 is provided with a transfer groove 723, and the upper end of the lower straight rod 71 is fixed with a transfer shaft 711, and the upper end of the transfer shaft 711 penetrates the bottom end surface of the upper straight rod 72, and the transfer The upper end of the shaft 711 penetrates into the transfer groove 723, the upper end of the transfer shaft 711 is fixedly provided with a jacking block 712, the upper end of the jacking block 712 is provided with a first toothed disc 714, and the control part 9 is fixedly arranged On the upper straight rod 72 outside the right side of the transfer groove 723, a second sliding connection groove 91 is arranged in the upper end of the control part 9, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com