A double-flange support device for a rotating ultrasonic transducer sleeve

A technology of rotating ultrasonic and supporting devices, which is applied in the direction of vibrating fluid, metal processing equipment, and manufacturing tools. The effect of tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

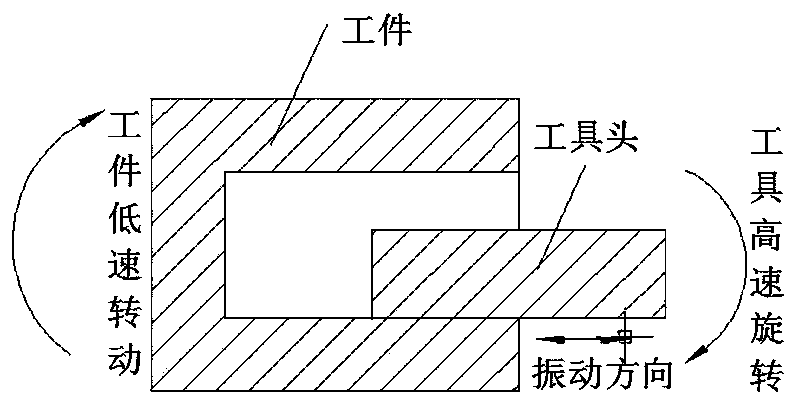

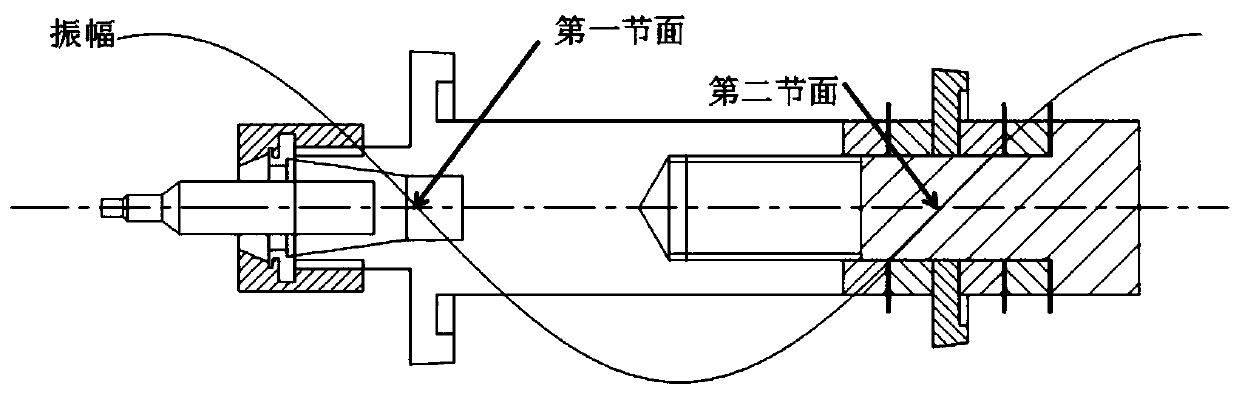

[0020] The invention relates to a double-flange support device for a rotary ultrasonic transducer sleeve. It is part of the high-speed rotating ultrasonic grinding spindle. Under the support of two flanges, the ultrasonic transducer rotates stably at high speed (10000rpm) with the main shaft.

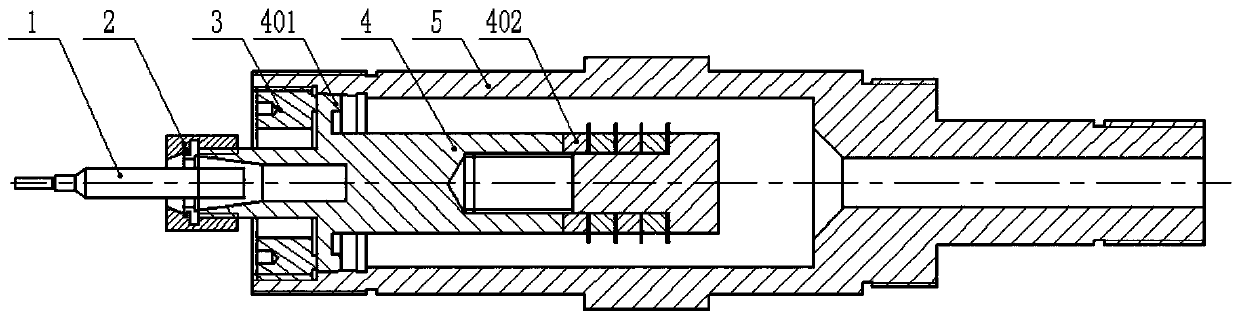

[0021] Figure 5 The ultrasonic transducer 4 shown in FIG. The piezoelectric ceramic sheet 403 , the second flange 404 and the electrode sheet 405 are located between the horn 401 of the front cover and the rear cover 406 . The two are connected by threads. The outer cylindrical surface of the first flange 402 in the horn 401 of the front cover is made into a tapered surface. The tapered surface cooperates with the corresponding tapered surface on the main shaft. And press i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com