Motor vehicle with axle bracket

A technology for motor vehicles and axles, which is applied in the direction of suspension, power device, elastic suspension, etc., and can solve problems such as multiple structural spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

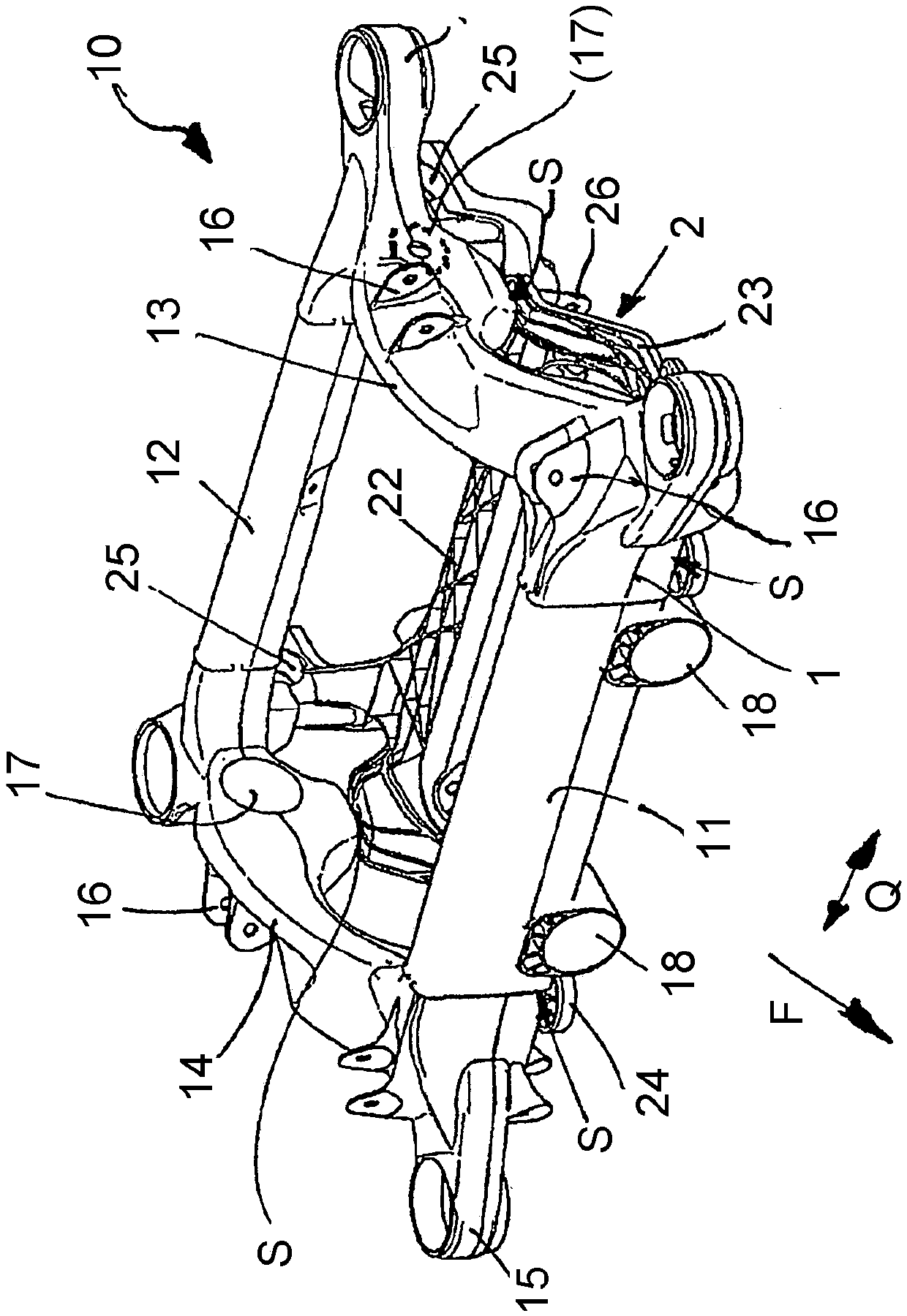

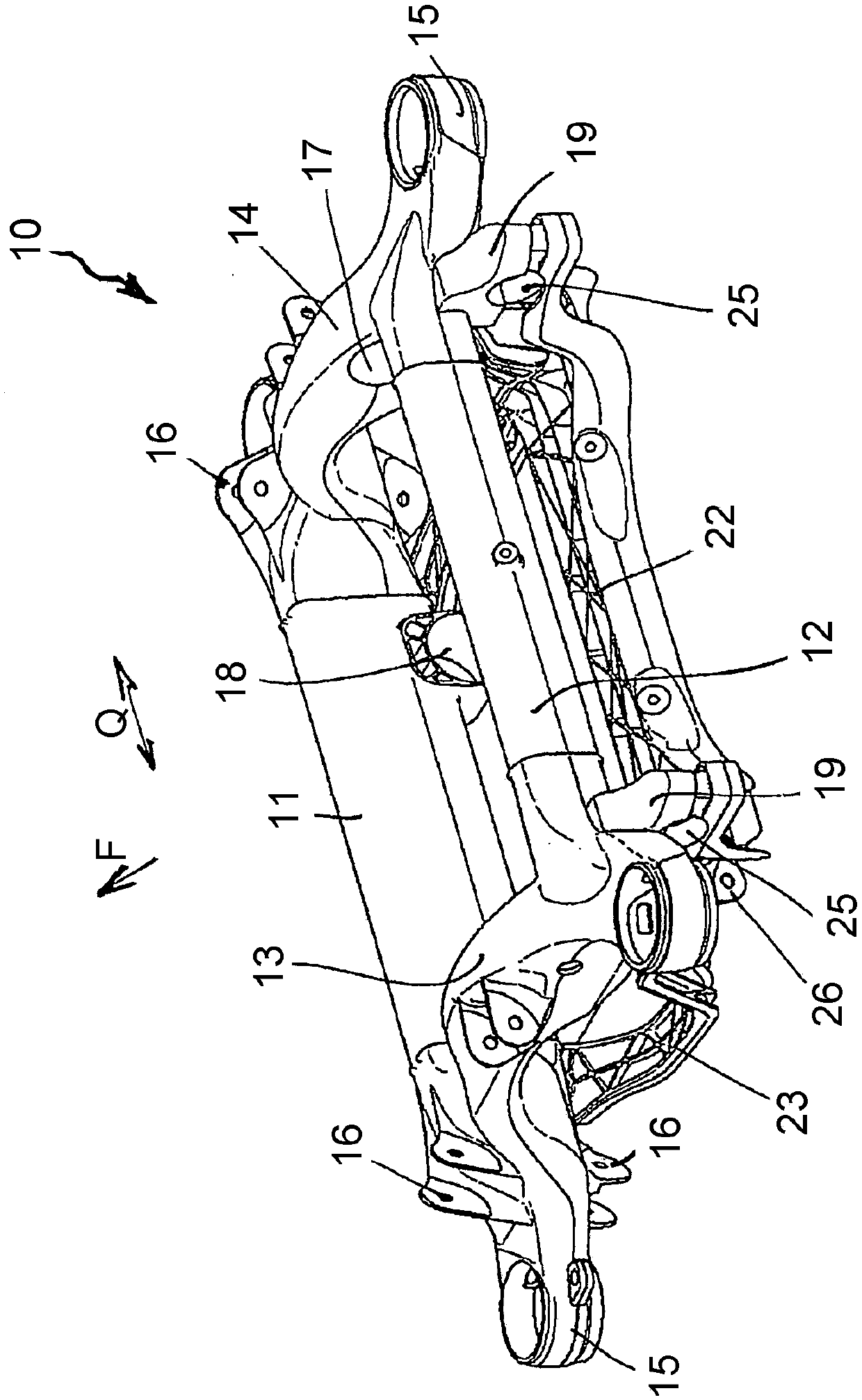

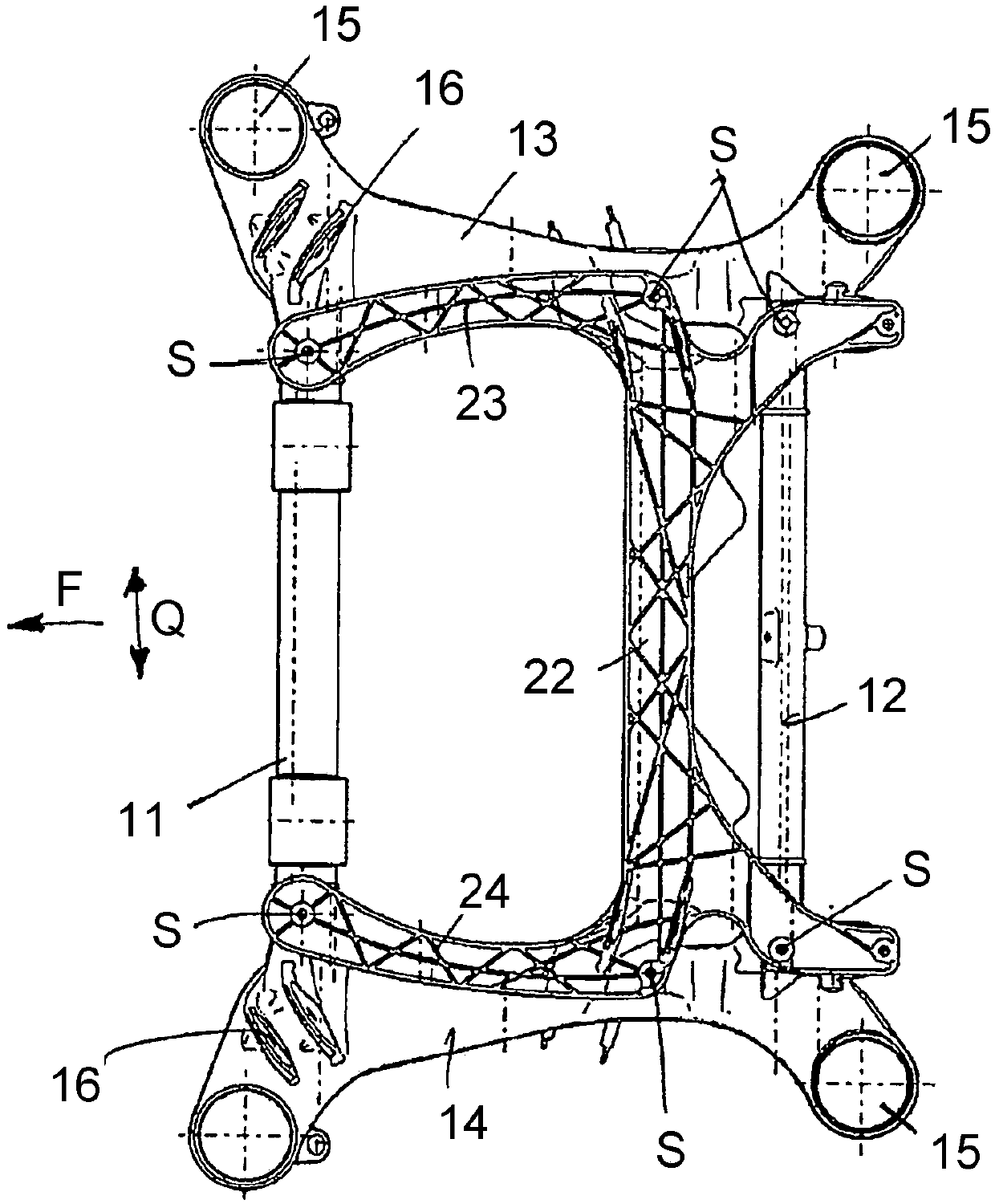

[0015] first reference Figures 1 to 3 , the first structural unit is marked with reference numeral 1 and the second structural unit is marked with reference numeral 2, said first structural unit and the second structural unit are assembled together (eg figure 1 shown) form the axle support 10 according to the present invention. The cross member 11 in front in the direction of travel F of the vehicle equipped with the axle support 10 and oriented in the transverse direction Q of the vehicle, like the cross member 12 arranged further behind and parallel to it, is formed as an extruded profile and on both sides The end faces are materially and also positively connected to a side member 13 (left as viewed in the direction of travel) or 14 (right as viewed in the direction of travel) oriented in the direction of travel F. Receptacles 15 for elastic bearings (not shown) via which the axle carrier 10 is detachably fastened or fastened to the passenger car are provided at the ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com