Wire winding mechanism and moving platform with same

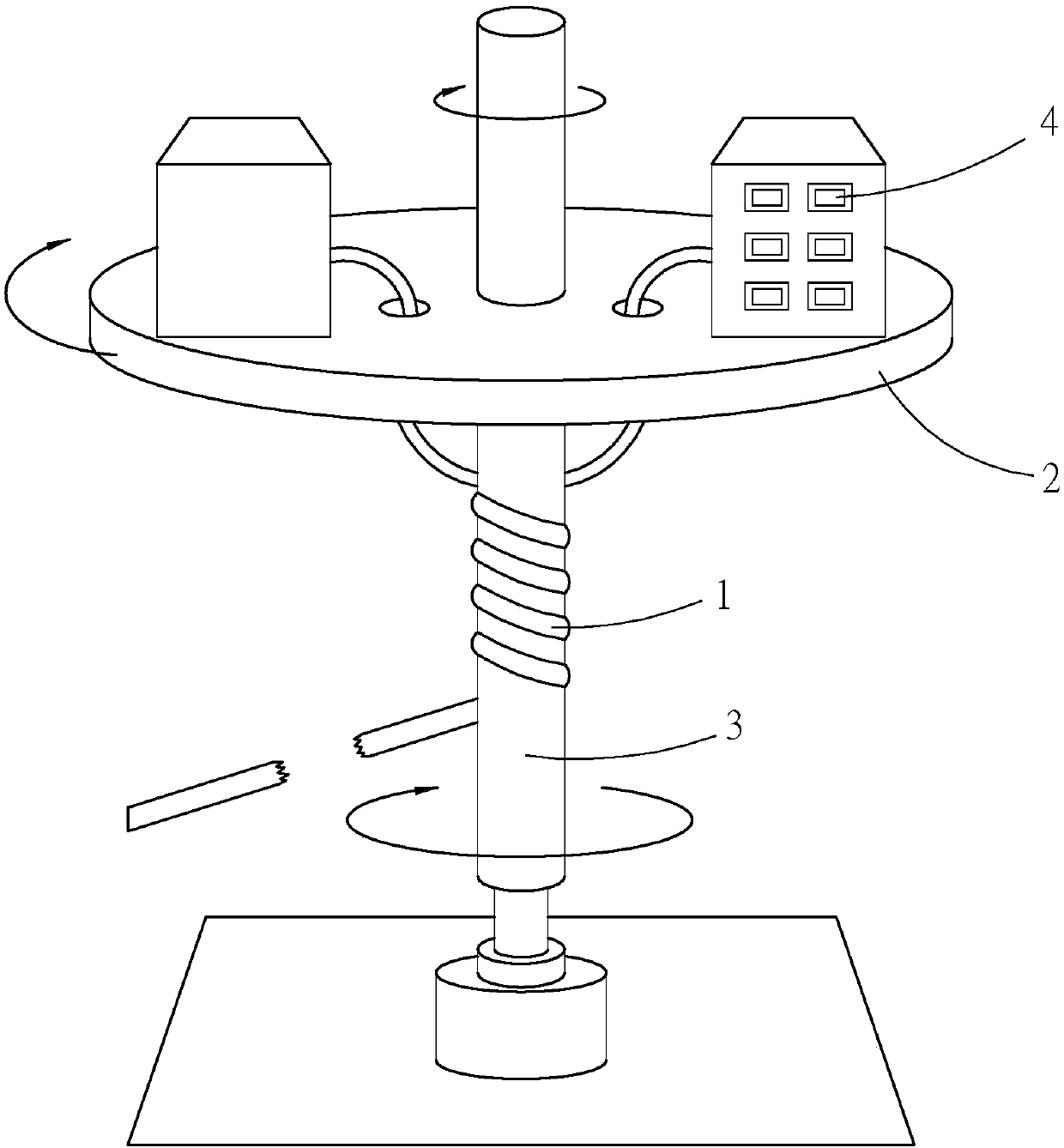

A technology of winding mechanism and motion platform, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as use restrictions, unsuitable cable use, signal transmission interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

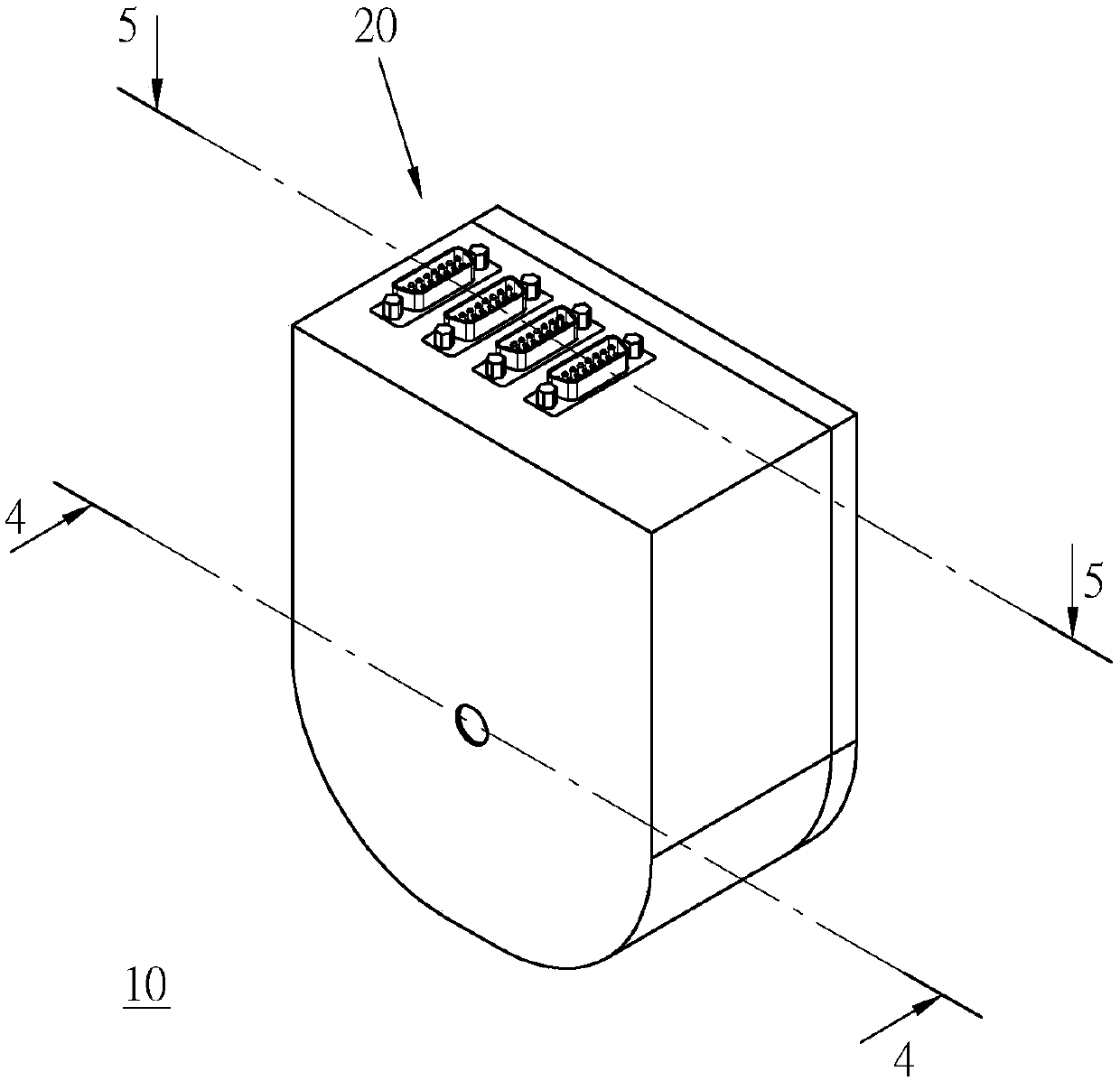

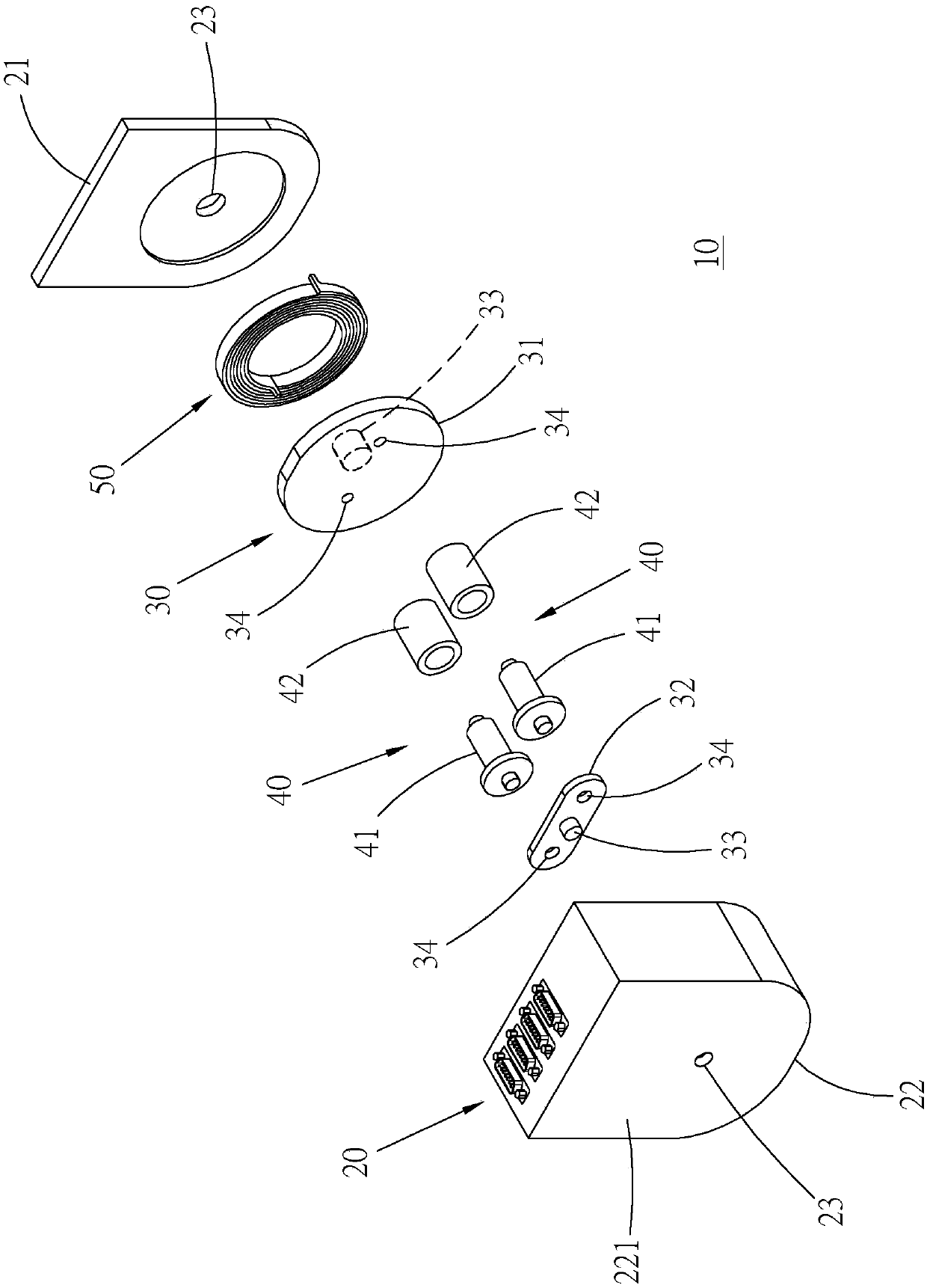

[0025] First, see Figure 2 to Figure 5 As shown, a wire winding mechanism 10 is provided in an embodiment of the present invention, which mainly includes a housing base 20 , a base member 30 , two support members 40 and an elastic member 50 .

[0026] The housing base 20 has an end body 21 , a housing 22 and two shaft holes 23 . The end body 21 is in the shape of a plate, and the shell 22 is in the shape of a hollow cap, and the end body 21 and the shell 22 are docked with each other, so that an appropriate volume of accommodation space is formed between the end body 21 and the shell 22 to accommodate components other than the shell seat and The line body to be rolled up is contained therein. The two shaft holes 23 are coaxially and correspondingly disposed on the end body 21 and a pair of shell plates 221 of the shell 22 away from the end body.

[0027] The base part 30 is located in the receiving space of the shell base 20 and has a turntable 31 , an adapter seat 32 , two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap