Automobile U-shaped bolt correction tool

A U-shaped and bolt technology, applied in the field of automobile U-shaped bolt correction tooling, can solve problems such as bolt damage, improve the quality of correction, reduce the possibility of fracture damage, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

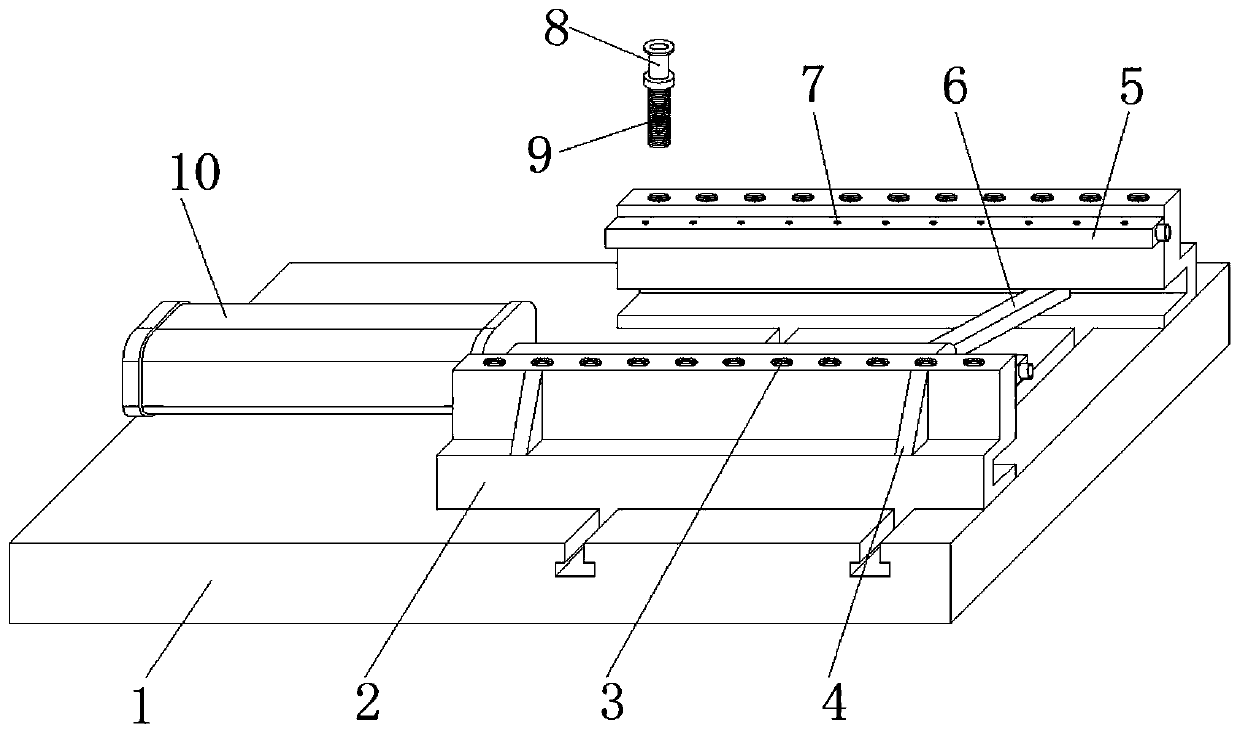

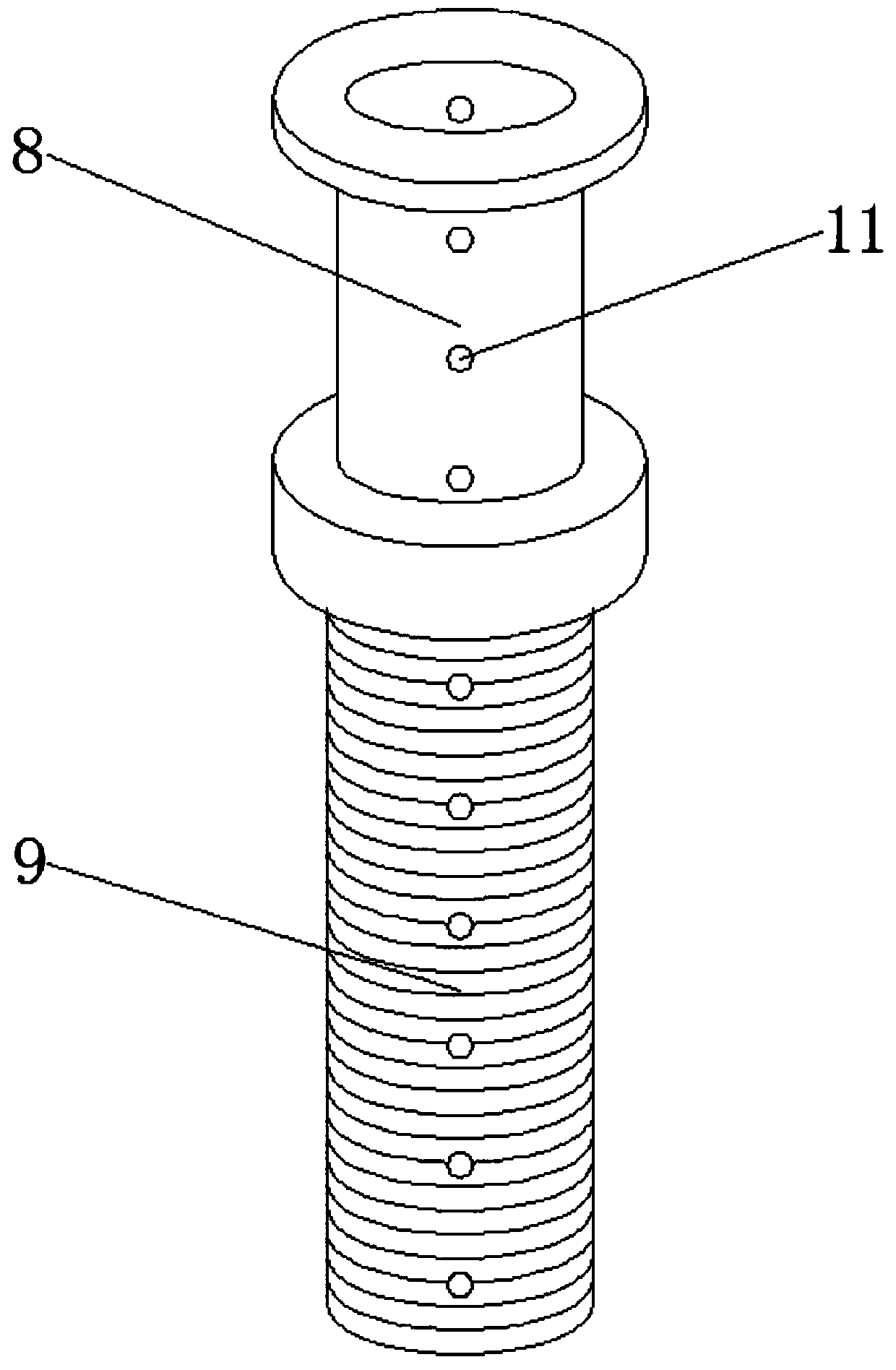

[0025] refer to Figure 1-2 , a U-shaped bolt correction tool for automobiles, comprising a bottom plate 1, a correction chute is provided on the top outer wall of the bottom plate 1, and a correction plate 2 is slidably connected to both sides of the inner wall of the correction chute, and a correction plate 2 is provided on the top outer wall of the correction plate 2. Hole 3, and the top of the outer wall on the opposite side of the two correction plates 2 is fixed with an air supply pipe 5 by screws, and the top outer wall of the air supply pipe 5 and the outer wall of the side contacting the correction plate 2 have an air outlet 7, and the two correction plates The inner walls of 2 are connected with connecting rod 6 by hinges, and the top outer wall of base plate 1 is fixed with hydraulic cylinder 10 by screws, and one end of the piston rod of hydraulic cylinder 10 is connected to one end of connecting rod 6 by hinges.

[0026] In the present invention, the inner wall of...

Embodiment 2

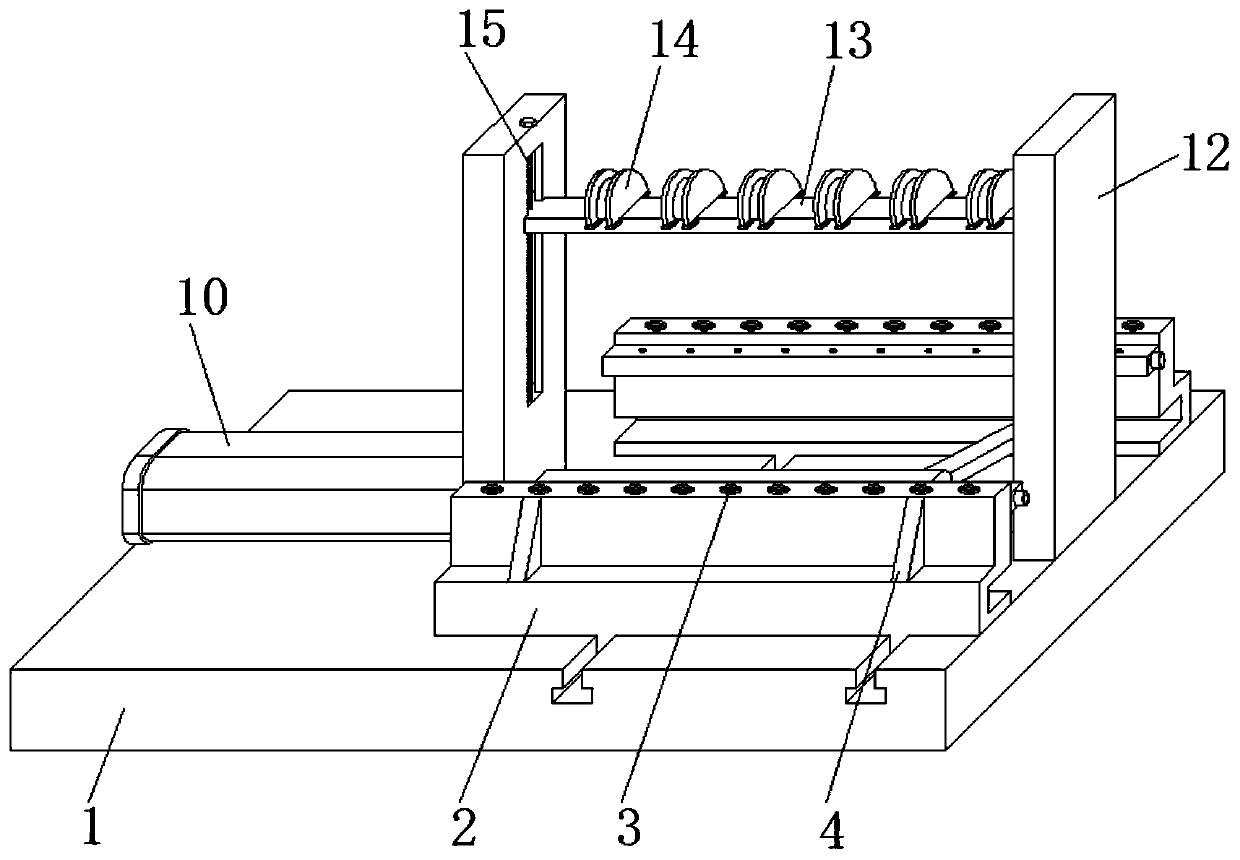

[0031] refer to image 3 , a kind of automobile U-shaped bolt correction tooling, the top outer wall of the base plate 1 is welded with vertical plates 12 on both sides, and the outer walls of the opposite sides of the two vertical plates 12 are provided with slide chute, and the inner wall of the slide chute is slidably connected with a slide plate 13.

[0032] Wherein, the top outer wall of the slide plate 13 has a splint chute, and the inner wall of the splint chute is slidably connected with a positioning splint 14, and the positioning splint 14 clamps and supports the U-shaped bolt, which can ensure the stability of the U-shaped bolt in the calibration process.

[0033] Wherein, the top outer wall of the vertical plate 12 has a threaded rod installation hole, and the inner wall of the threaded rod installation hole is sleeved with a threaded rod 15 , and the slide plate 13 is connected to the outer wall of the threaded rod 15 by threads.

[0034] Working principle: Turn ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap