Device and method for simulating full sea depth pressure battery performance test

A technology for testing device and battery performance, which is applied in the direction of measuring device, measuring electricity, measuring electric variables, etc., and can solve the problems that lithium iron phosphate batteries have never been tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

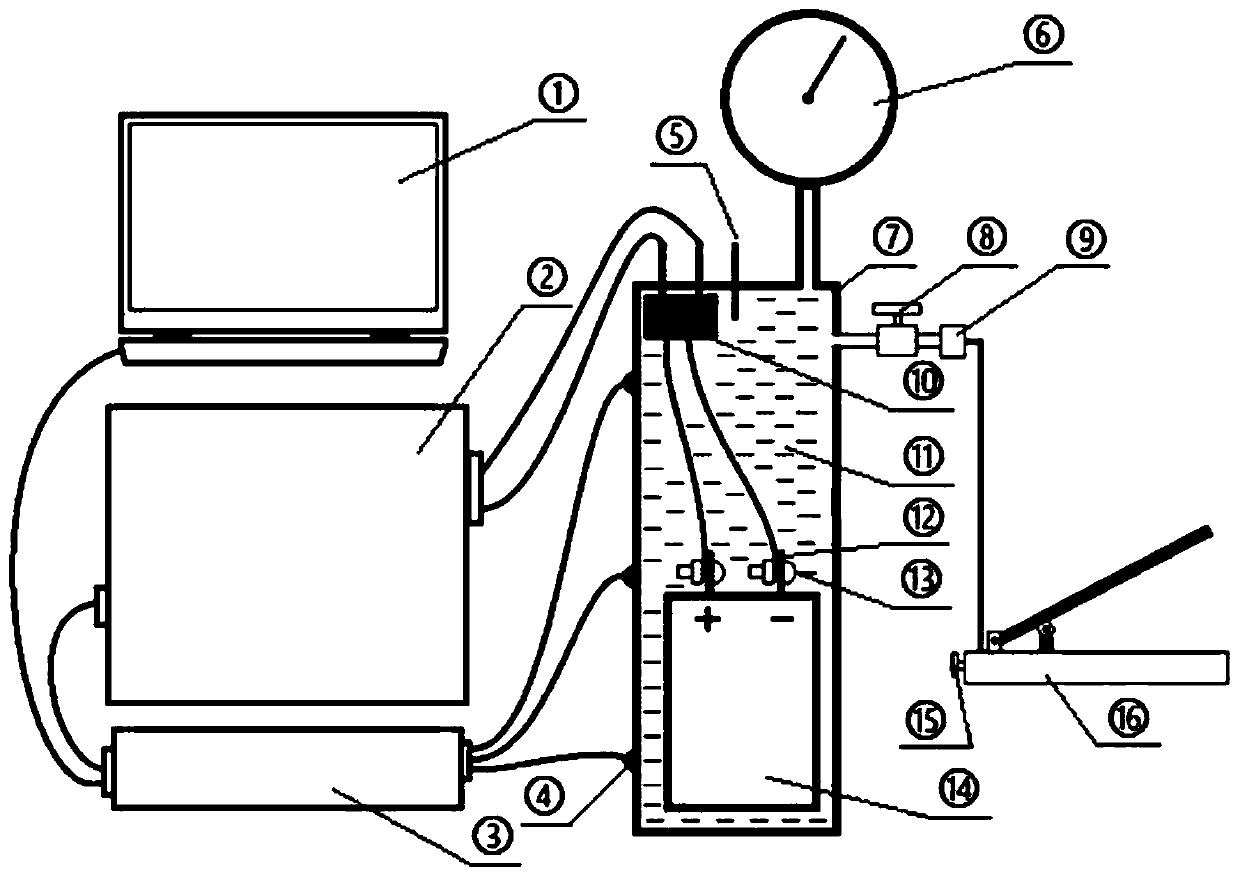

[0024] The experimental equipment in this example uses power battery testing equipment, a milliohm meter, a 100MPa pressure test barrel, and a manual booster pump; the test object is a 3AH lithium iron phosphate soft pack battery; the test temperature is 20°C and 3°C; the test pressure is 0.1MPa -100Mpa.

[0025] The structure of this device is as figure 1 As shown: the cast iron pressure vessel 7 and the pressurizing mechanism 16 are connected with a high-pressure pipeline through a valve 8 and a pressurized pipeline interface 9 . The test battery tab 12 is connected with the circuit plug 10 and the sealing socket 5 on the top of the cast iron pressure vessel through bolts 13, and the plug 10 is connected with the battery test platform 2 through wires. The thermocouple 4 is arranged on the surface of the cast iron pressure vessel and connected with the auxiliary channel 3 . The battery test platform communicates with the host computer by connecting the auxiliary channel.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com