A flexible protective fixture for precision assembly

A technology for protecting jigs and fixtures, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as difficulty in meeting process concentration, small processing technology, movement accuracy damage, etc., to save R&D and cost, improve R&D speed, and preparation time. shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and embodiments.

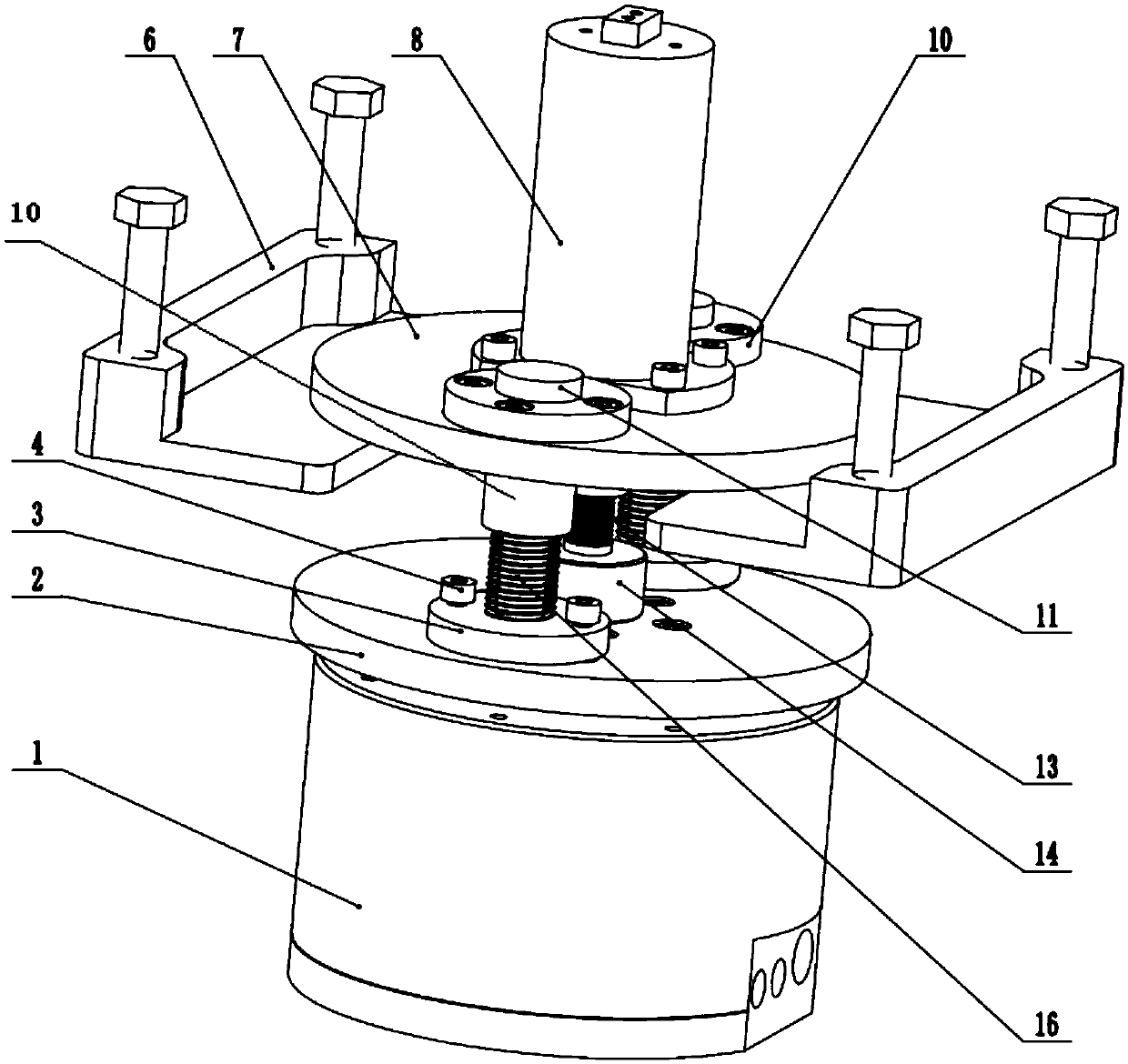

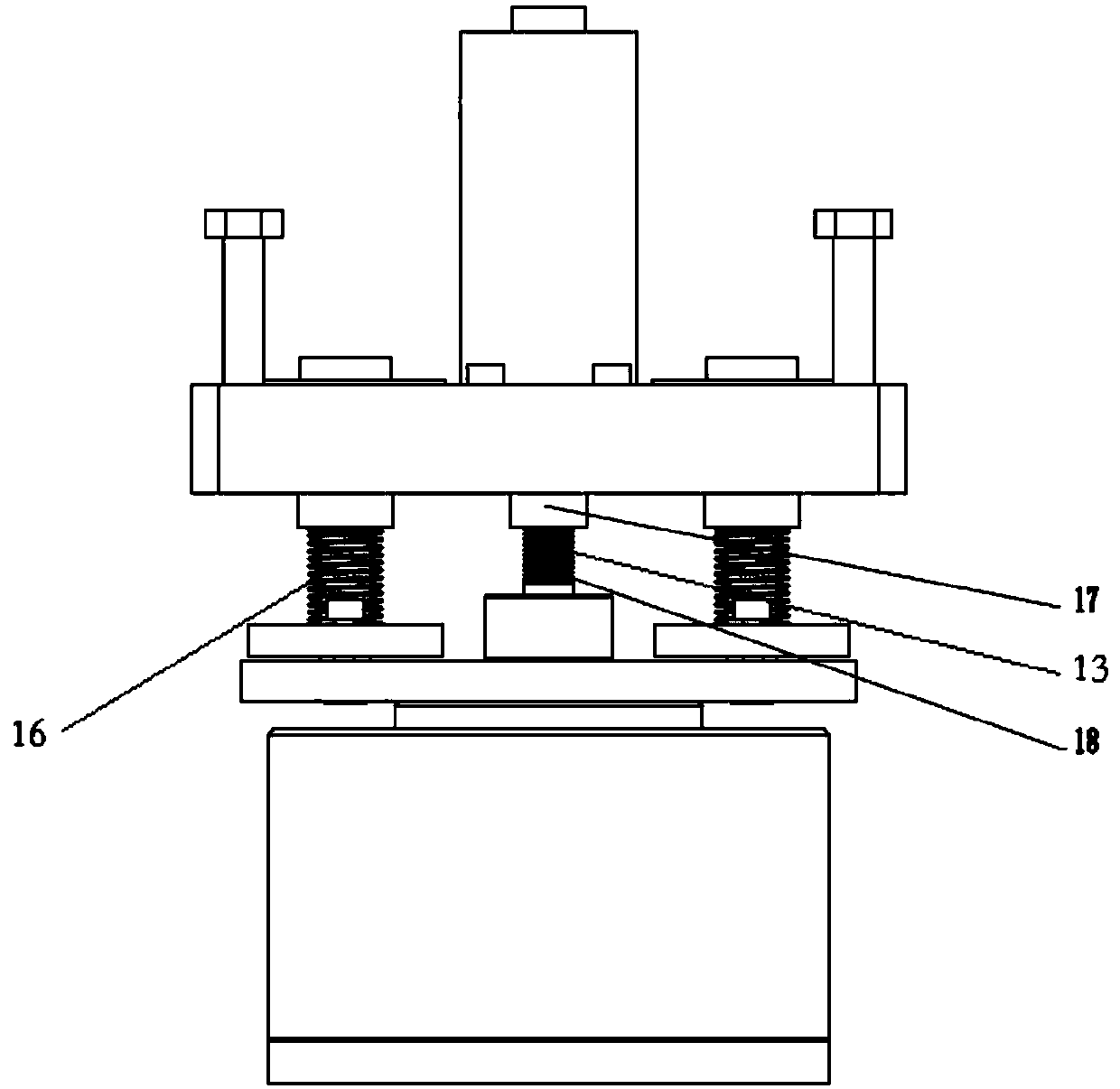

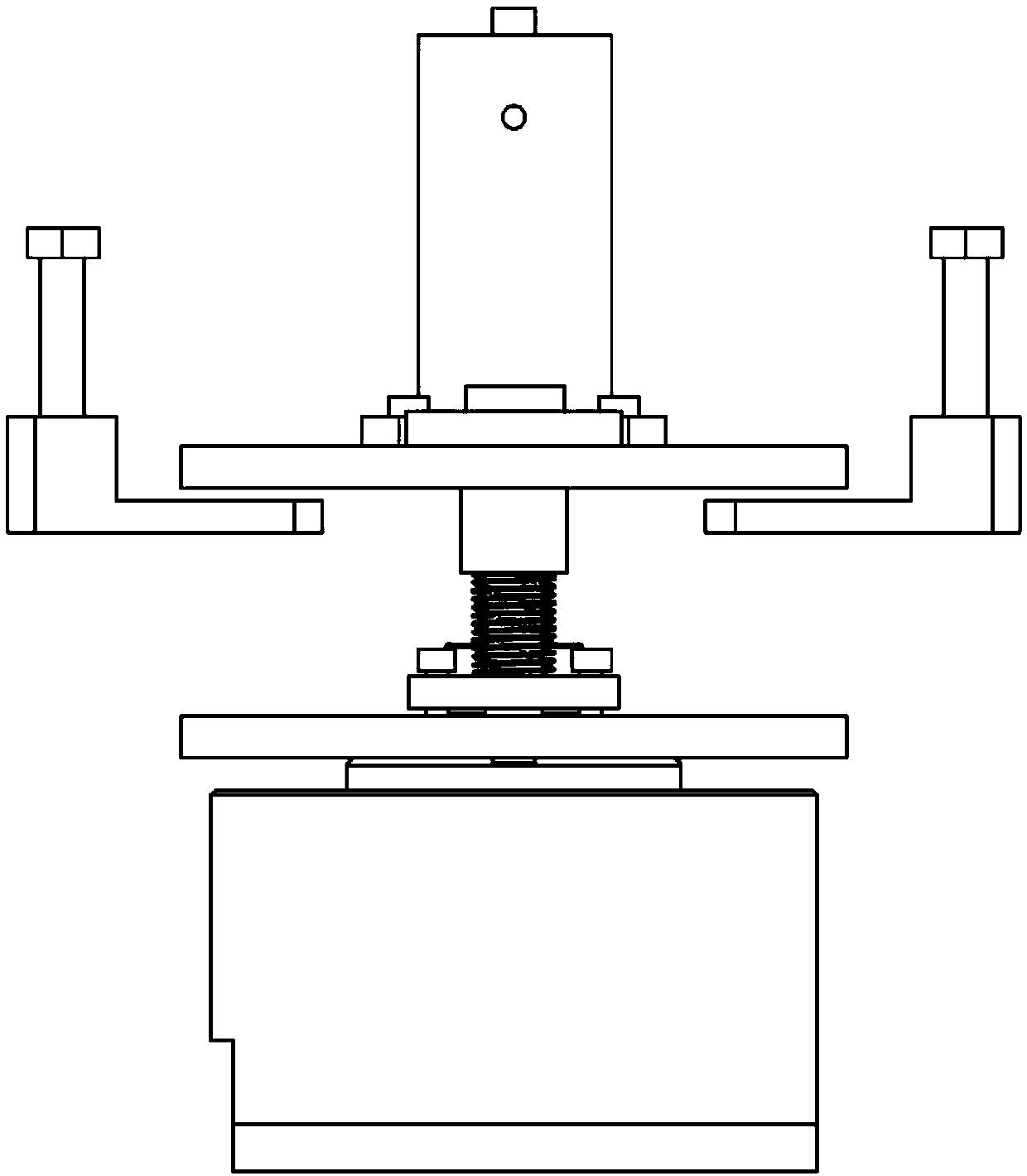

[0027] The present invention provides a flexible protective clamp for precision assembly, see attached Figure 1-3 , Including: turntable 1, turntable connecting plate 2, pallet 6, clamp adapter plate 7, clamp 8, center spring 13, force sensor 14, spring adjustment sleeve 17, force sensor connecting rod 18, sliding adjustment assembly and force monitoring assembly ;

[0028] The turntable 1 is a precision motion platform;

[0029] The upper and lower end faces of the force sensor 14 are provided with studs;

[0030] The spring adjusting sleeve 17 is a cylindrical tube with one end open and one end closed;

[0031] The center of the turntable connecting plate 2 is machined with threaded holes for connecting the lower end stud of the force sensor 14, and the end surface is machined with threaded holes for connecting the sliding adjustment component;

[0032] See attached Figu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap