A simple magnetizer

A magnetizer, a simple technology, applied in the direction of magnetic objects, circuits, electrical components, etc., can solve the problems of uneven magnetic force of components, components unable to meet the requirements of use, without considering the improper placement of components, etc., to improve the magnetization The effect of efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

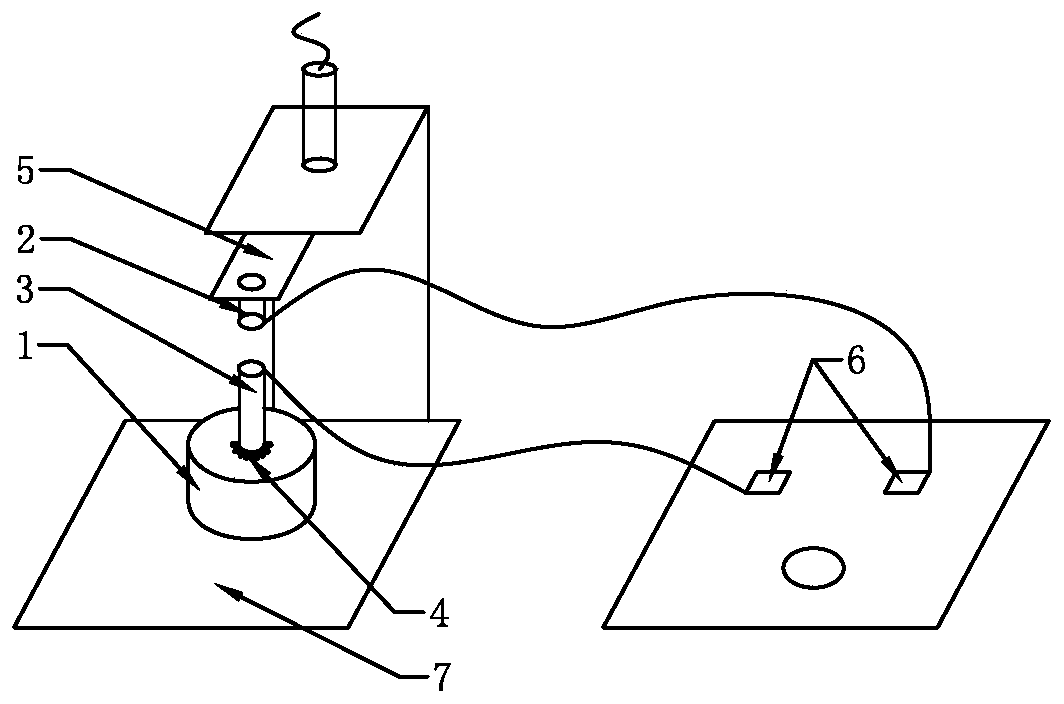

[0013] refer to figure 1 , a simple magnetizing machine of the present invention, including an operation assembly and a detection assembly, the operation assembly includes a base 1, an indenter 2, and a fixed head 3 for placing components protrudes from the base 1, and the fixed The bottom of the head 3 is provided with magnetizing magnetic poles 4, and the indenter 2 is connected with a power device 5 that can drive it to move up and down. The detection assembly is electrically connected with the operation assembly. The detection device at the 3 position, the detection device is respectively connected with the display screen 6 that can display the magnetic force value, the present invention can detect the workpiece in real time by setting the detection device at the position of the indenter 2 and the fixed head 3 and connecting the display screen 6 The magnetic value at the upper and lower ends can avoid magnetization defects caused by improper placement of components, vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com