An automatic magnetizer

A magnetizing machine and automatic technology, applied in the direction of magnetic objects, circuits, electrical components, etc., can solve the problems of high labor cost, high scrap rate, and inability to adapt to mass production, so as to improve the efficiency and success rate of magnetization, processing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

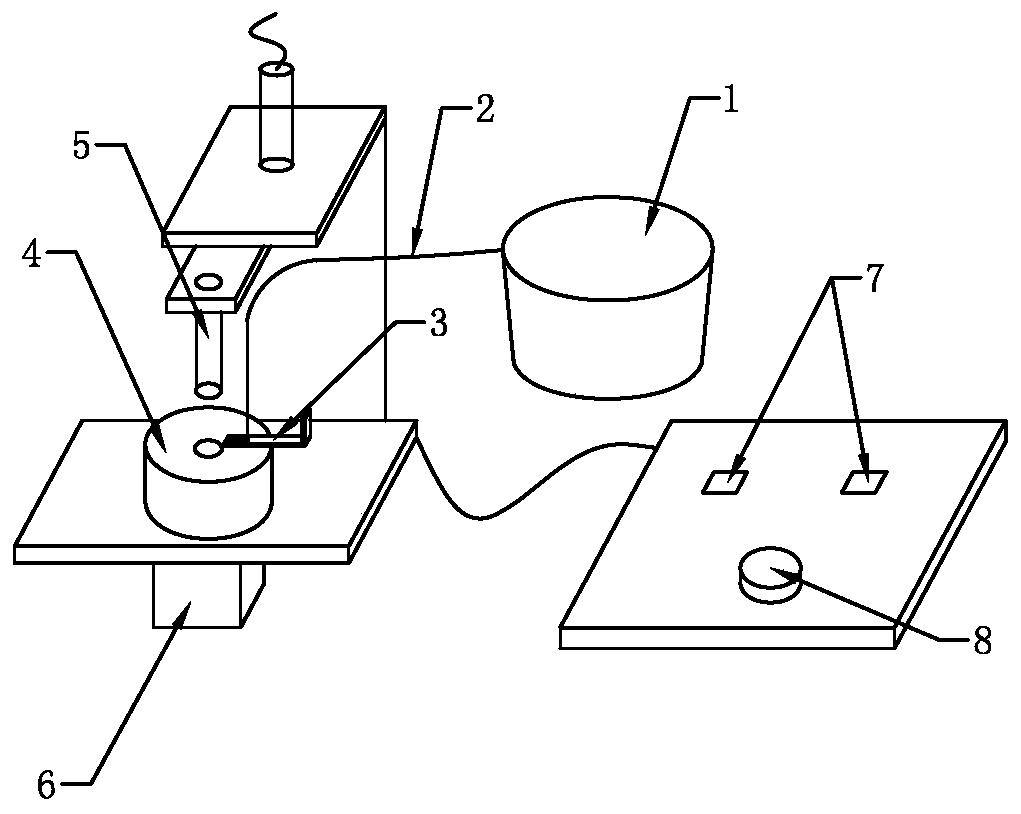

[0013] refer to figure 1 , a kind of automatic magnetizing machine of the present invention is characterized in that: it comprises working component and detection component, and described working component comprises rotary vibrating screen 1, and the feed channel 2 that is connected with it, and the other end of described feed channel 2 is Push block 3, described push block 3 is arranged on the top of magnetic charging head 4, described magnetic charging head 4 is provided with pressing block 5 and top block 6 respectively, and described pushing block 3, pressing block 5, top block 6 are respectively It is connected with a power device that drives its movement, and the detection component is electrically connected with the operation component. The detection component includes detection devices respectively arranged at the positions of the pressure block 5 and the top block 6, and the detection devices are respectively connected with magnetic value display The display screen 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com