Optical fiber coiling device group

A technology of optical fiber coiling and device assembly, which is applied in optics, light guides, optical components, etc., can solve problems such as uneven heat dissipation, visual blind spots, and large errors, and achieve efficient and high-quality water-cooled heat dissipation and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

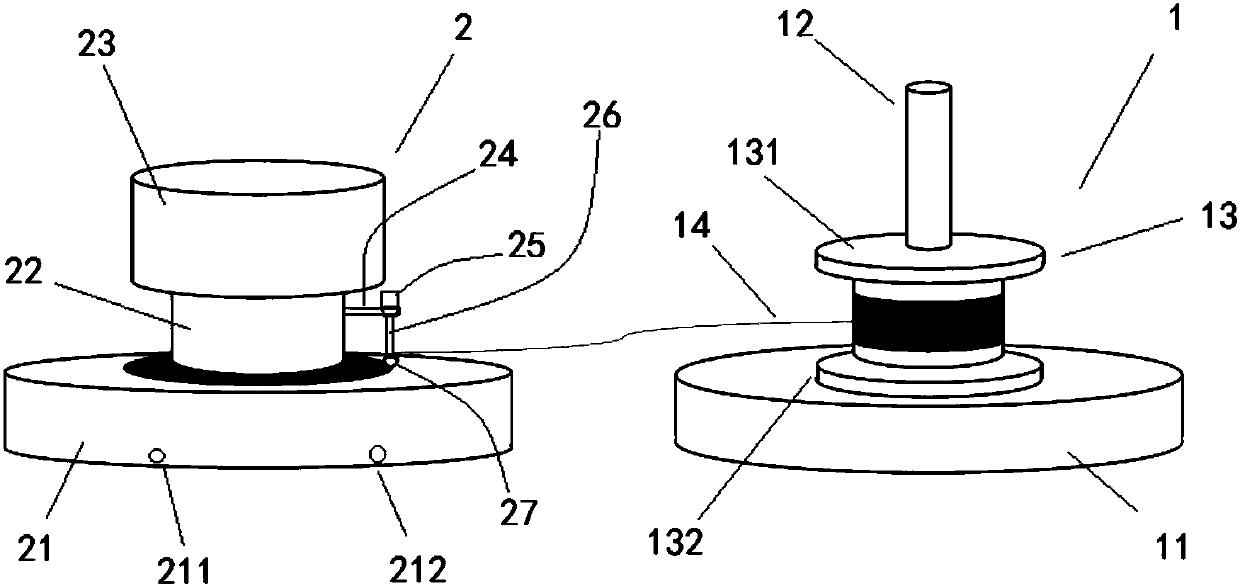

[0015] Such as figure 1 As shown, an optical fiber coiling device set includes an optical fiber transmission device 1 and an optical fiber coiling device 2 .

[0016] The optical fiber transmission device 1 includes a first base 11 and a first rotating shaft 12 vertically arranged at the center of the first base 11. The first rotating shaft 12 is sleeved with an optical fiber reel 13 for rough winding of optical fibers. The optical fiber reel 13 includes an upper optical fiber reel 131 and the lower optical fiber tray 132 , the lower optical fiber tray 132 is in contact with the upper end surface of the base 11 , and the optical fiber 14 is wound between the upper and lower optical fiber trays 131 and 132 .

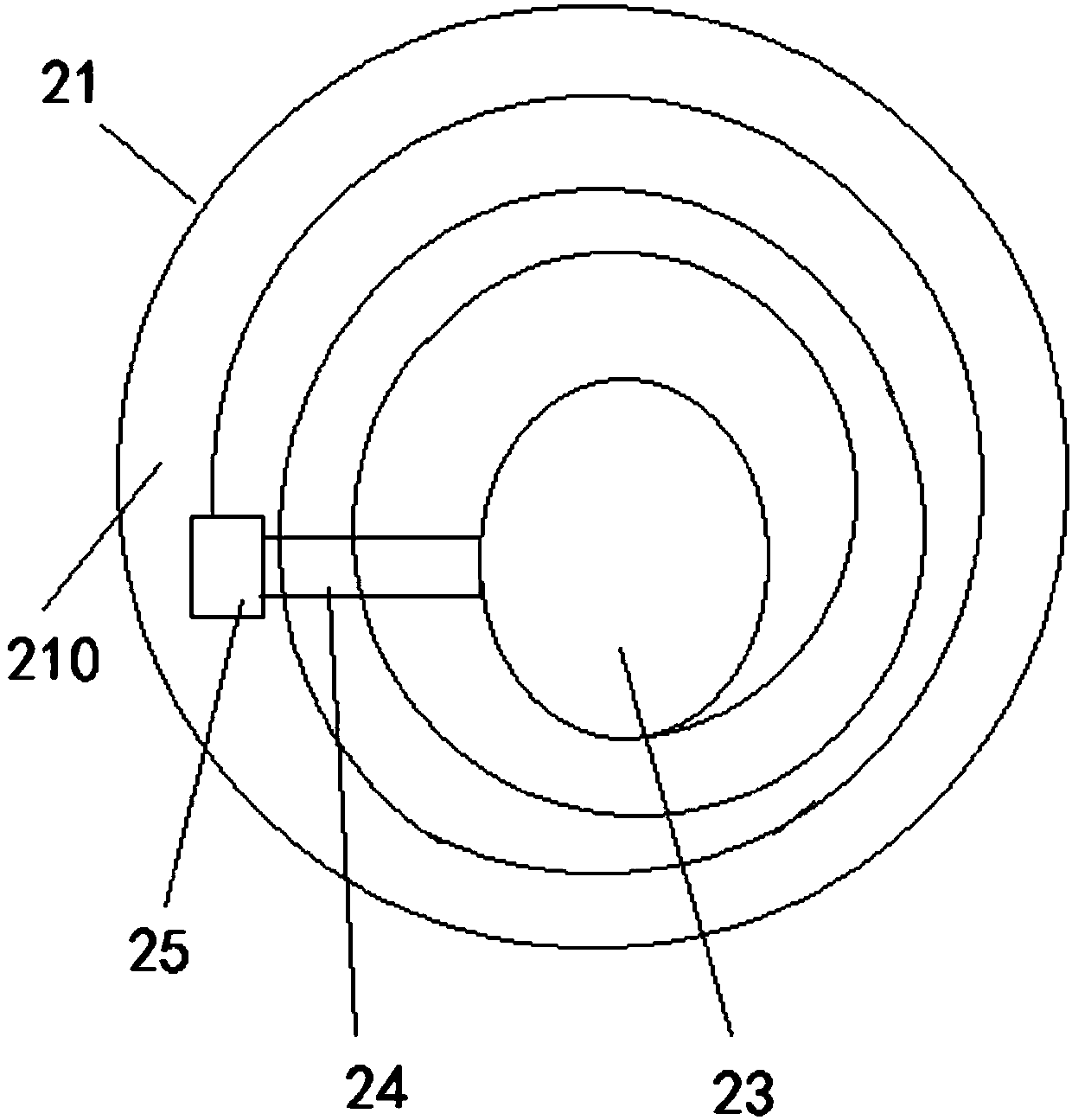

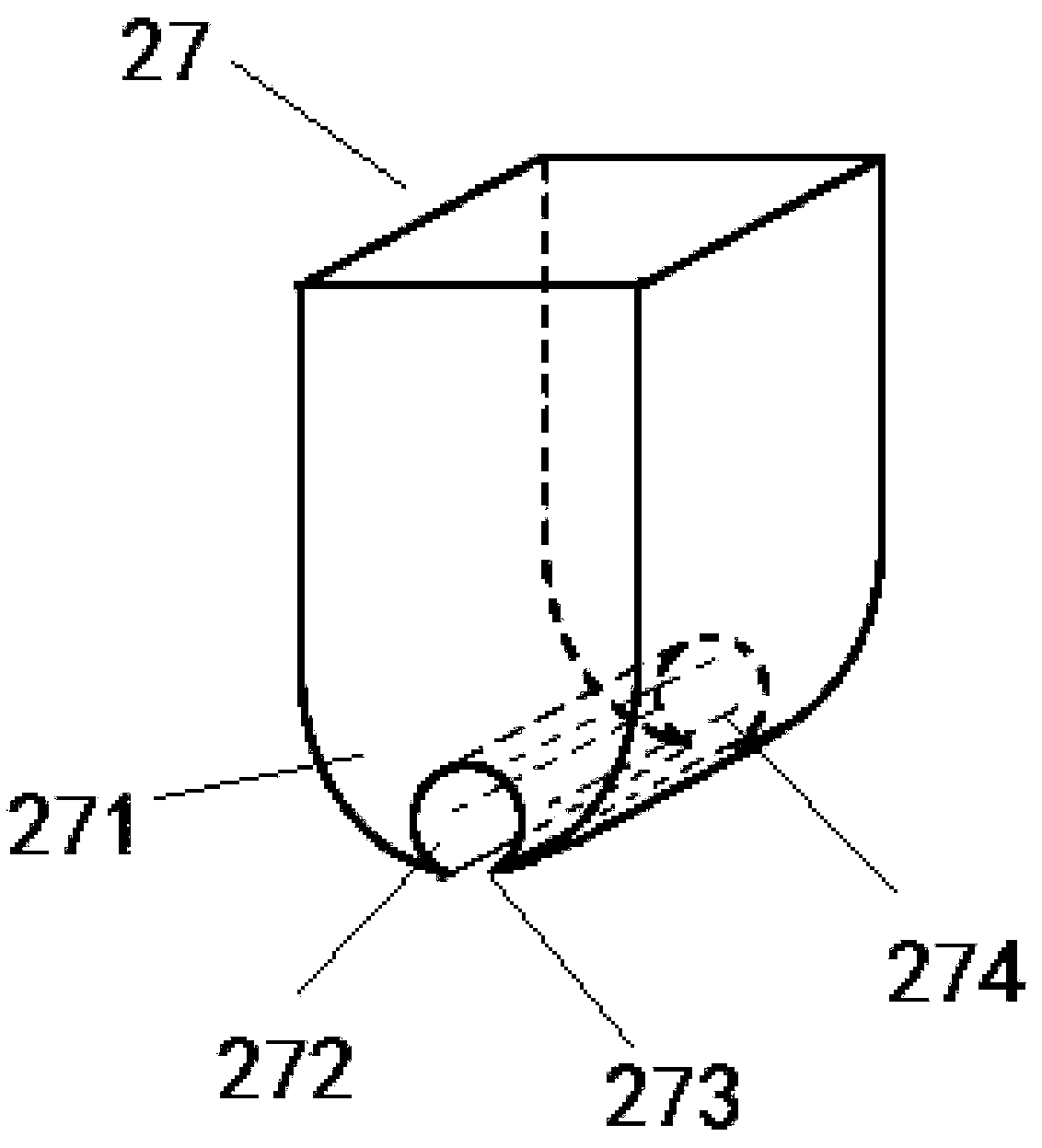

[0017...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap