Reluctance rotor having an additional inherent magnetization

A technology of rotors and rotor slices, applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., can solve problems such as efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

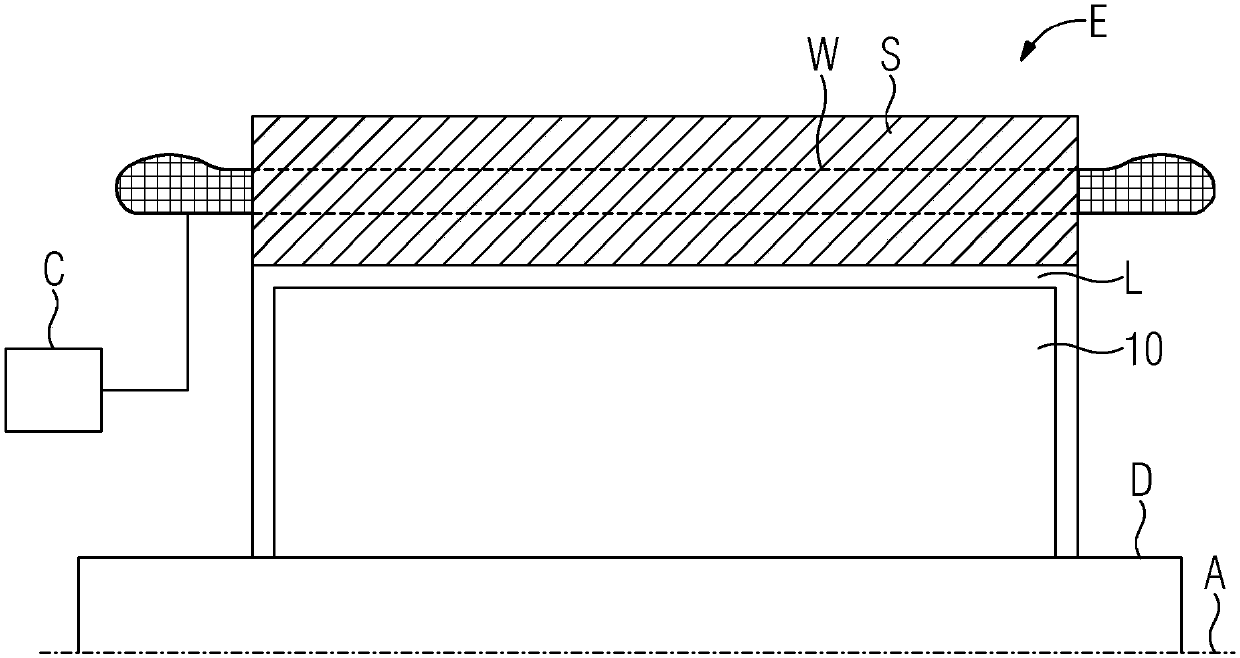

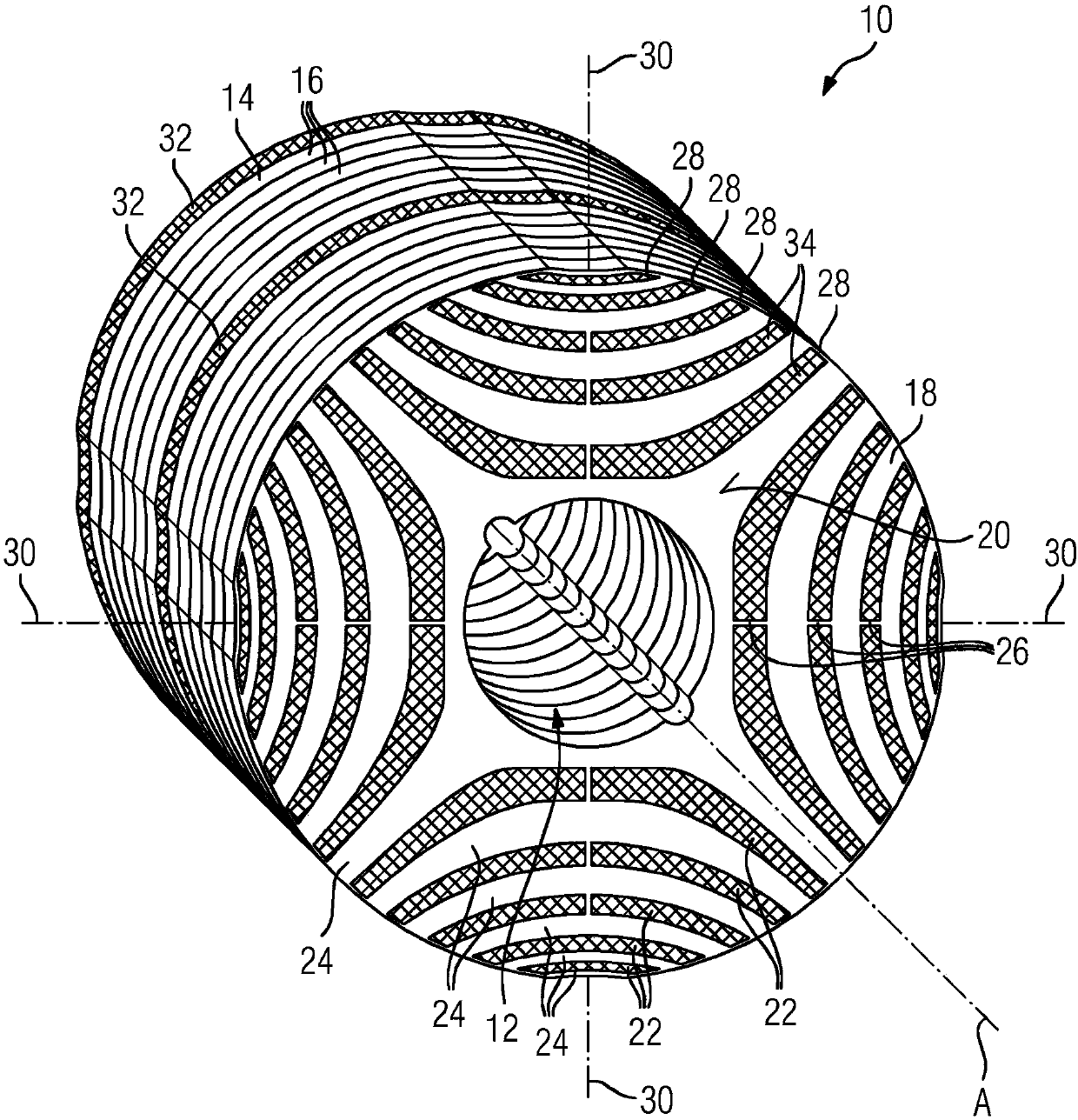

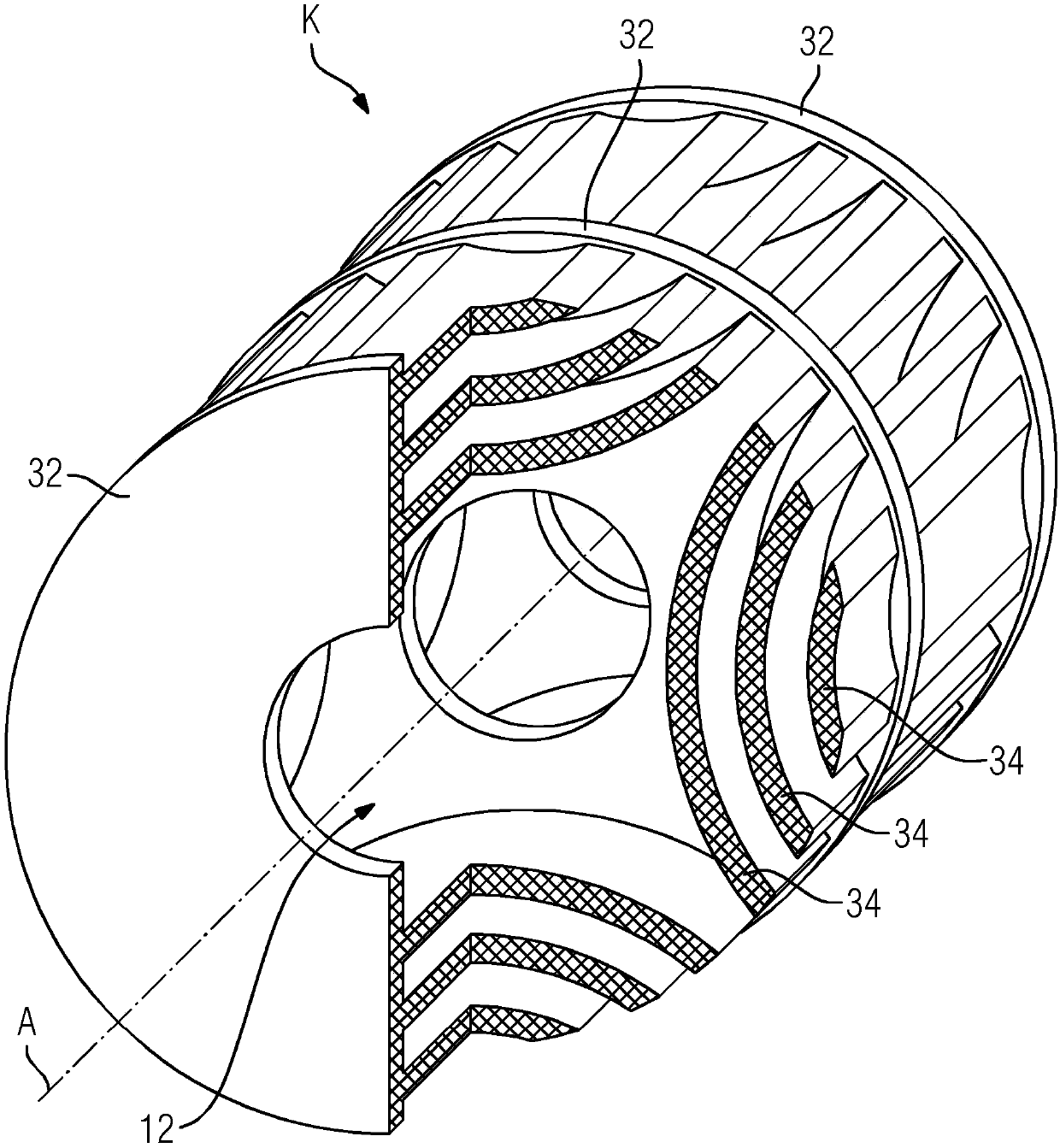

[0037] Through the through hole 12 of the rotor 10 ( figure 2 not shown in ) into shaft D. The diameter of the rotor 10 relative to the axis of rotation A in the radial direction may be greater than 20 cm. The length of the rotor 10 in the axial direction may be greater than 30 cm.

[0038] The rotor 10 has a laminated core 14 formed from a plurality of layers 16 as a magnetically active part. For clarity, in figure 2 Only some of the magnetic layers 16 are provided with reference numerals in . Between these layers there are electrically insulating layers in a known manner in order to prevent eddy currents in the laminated core 14 . exist figure 2 In the example shown, each layer 16 is formed from a soft magnetic rotor sheet 18 . Another name for rotor lamination is electrical steel lamination or transformer lamination.

[0039] exist figure 2 Among them, only the rotor plates 18 located on the end face 20 of the front end of the lamination stack 14 in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com