Self-adhesion device of impermeable membrane joint and self-adhesion type water interception curtain construction method thereof

An anti-seepage film and self-adhesive technology, which is applied in construction, infrastructure engineering, magnetic objects, etc., can solve the problems of poor anti-seepage effect, poor adhesion of the anti-seepage film, and loose lap joints. The effect of water interception and impermeability, tight bonding and smooth lap joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

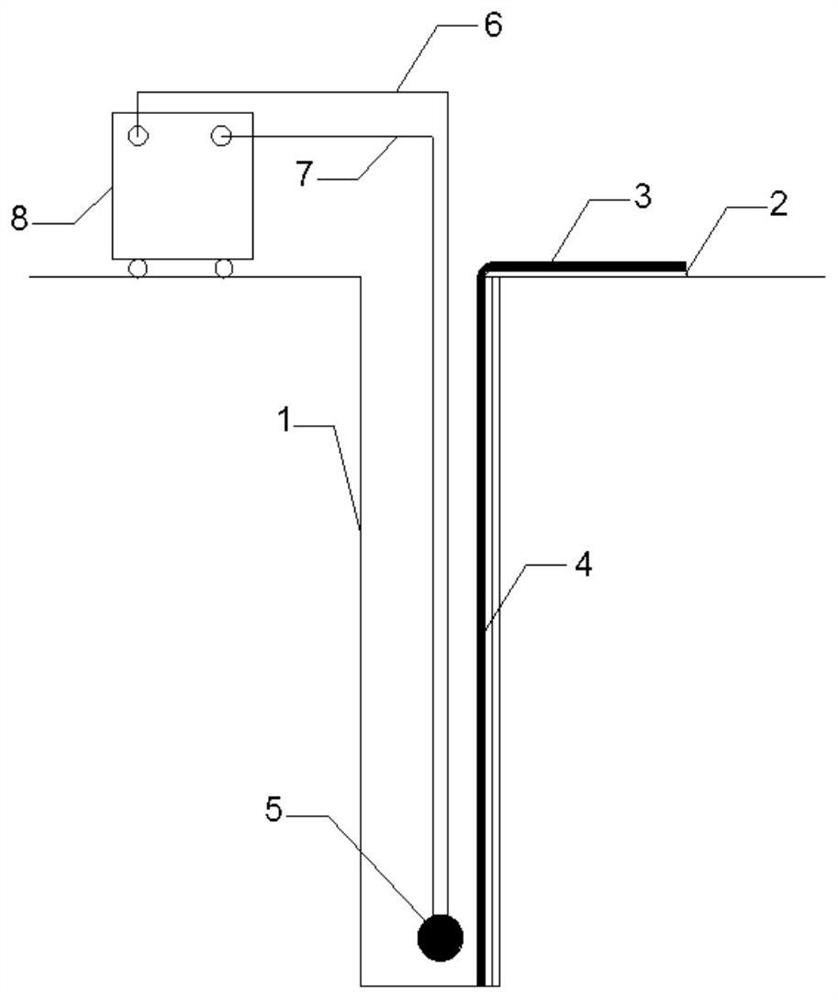

[0051] Step 1: The curtain wall groove section 1 is formed by double-wheel milling or hydraulic grabbing, with a width of 600mm and a depth of 50m. It is generally located in the water-retaining layer and encloses the foundation pit, pollutant diffusion area, open pit or underground mine. .

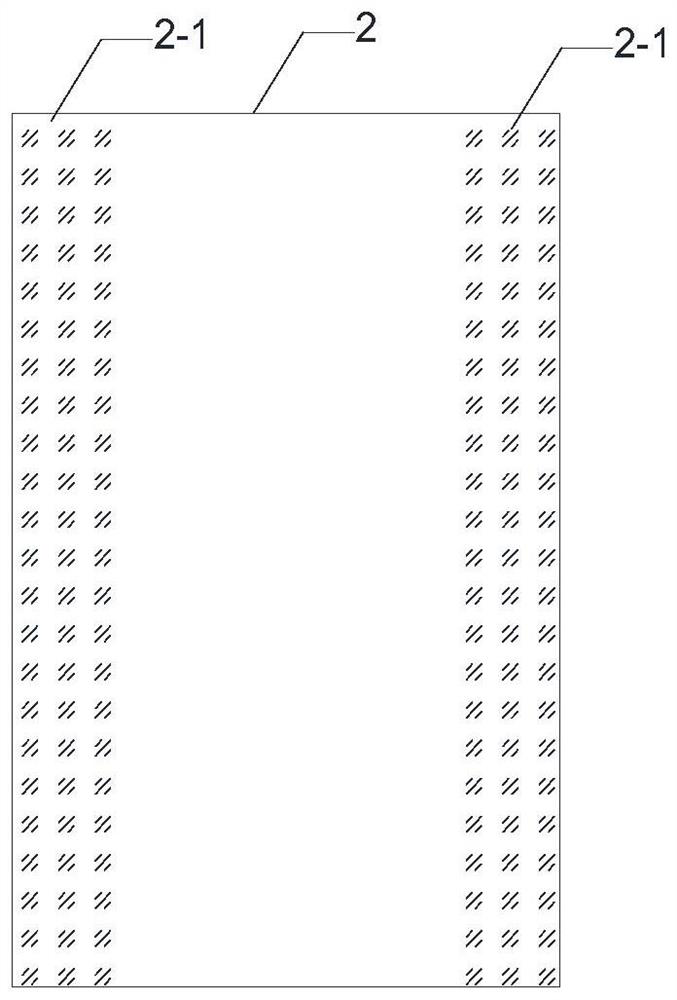

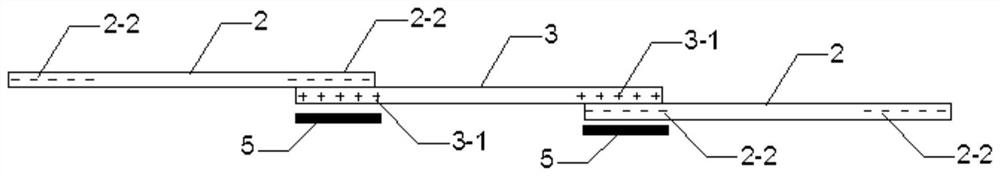

[0052] Step 2: After the curtain wall groove section 1 is formed, lower and lay the first anti-seepage membrane 2 close to the side of the curtain wall groove section 1, and the depth reaches the design depth. The top of the first anti-seepage membrane 2 can be fixed on the curtain wall with rivets. slot 1 slot;

[0053] Step 3: Lay down and lay the second anti-seepage membrane 3 close to the side of the groove section 1 of the curtain wall, and the depth reaches the design depth. The top of the membrane 3 is fixed to the notch of the curtain wall groove section 1 by rivets;

[0054] Step 4: Place the anti-seepage membrane joint self-bonding device on the overlapping section 4 of the fi...

Embodiment 2

[0068] Step 1: The curtain wall groove section 1 is formed by double-wheel milling or hydraulic grabbing, with a width of 600mm and a depth of 50m. It is generally located in the water-retaining layer and encloses the foundation pit, pollutant diffusion area, open pit or underground mine. .

[0069] Step 2: After the curtain wall groove section 1 is formed, lower and lay the first anti-seepage membrane 2 close to one side of the curtain wall groove section 1, the depth reaches the design depth, and the top of the first anti-seepage membrane 2 is fixed to the curtain wall groove with rivets Segment 1 notch;

[0070] Step 3: Lay down and lay the second anti-seepage membrane 3 close to the side of the groove section 1 of the curtain wall, and the depth reaches the design depth. The top of the membrane 3 is fixed to the notch of the curtain wall groove section 1 by rivets;

[0071] Step 4: Repeat steps 2 to 3 to bond all the first anti-seepage membranes 2 and the connected secon...

Embodiment 3

[0075] Step 1: The curtain wall groove section 1 is formed by double-wheel milling or hydraulic grabbing, with a width of 600mm and a depth of 50m. It is generally located in the water-retaining layer and encloses the foundation pit, pollutant diffusion area, open pit or underground mine. .

[0076] Step 2: After the curtain wall groove section 1 is formed, lower and lay the first anti-seepage membrane 2 close to one side of the curtain wall groove section 1, the depth reaches the design depth, and the top of the first anti-seepage membrane 2 is fixed to the curtain wall groove with rivets Segment 1 notch;

[0077] Step 3: Lay down and lay the second anti-seepage membrane 3 close to the side of the groove section 1 of the curtain wall, and the depth reaches the design depth. The top of the membrane 3 is fixed to the notch of the curtain wall groove section 1 by rivets;

[0078] Step 4: Place the anti-seepage membrane joint self-bonding device on the overlapping section 4 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com