A kind of graphene thick film with high thermal conductivity and preparation method thereof

A high thermal conductivity graphite and graphene film technology, applied in the direction of graphene, nano-carbon, etc., can solve problems such as unevenness and large spacing between graphene sheets, and achieve improved orientation, smooth thermal conduction channels, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

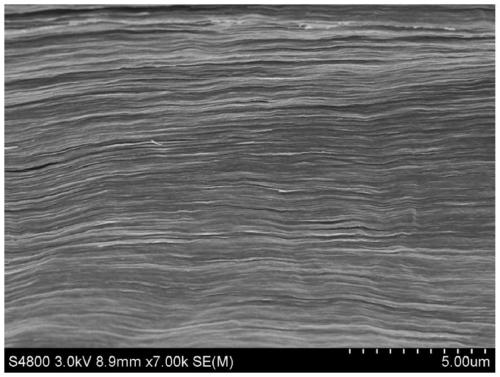

[0023] (1) Graphene oxide with an average size greater than 50 μm is formulated into a graphene oxide aqueous solution with a concentration of 7 mg / mL, and a graphene oxide solution with a thickness of 5 mm is spread to form a film by a scraping film method, and then dried naturally to obtain a graphene oxide film.

[0024] (2) Composite two graphene oxide films with a size of 8cm*8cm by liquid coating, specifically: uniformly coat a layer of graphene oxide aqueous solution with a concentration of 4mg / mL on the surface of the graphene oxide film, and then Bond multiple graphene oxide films together along the thickness direction.

[0025] (3) Place the bonded graphene oxide composite film in an oven for drying, and the temperature of the oven is 40°C.

[0026] (4) Place the dried graphene oxide composite and the original graphene film in the hot-pressing chamber of the hot-pressing machine, heat up to 200°C at a rate of 2°C / min, and then heat-press, and repeat the following hot...

Embodiment 2

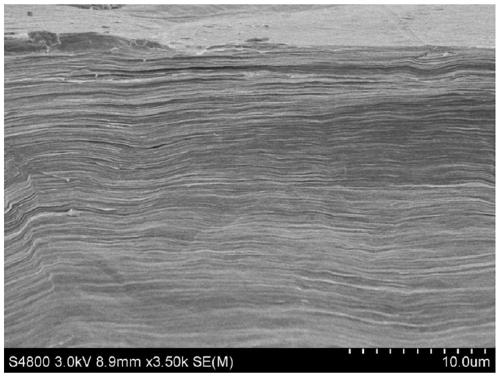

[0030] (1) Graphene oxide with an average size greater than 50 μm is formulated into a graphene oxide aqueous solution with a concentration of 7 mg / mL, and a graphene oxide solution with a thickness of 5 mm is spread to form a film by a scraping film method, and then dried naturally to obtain a graphene oxide film.

[0031](2) Coating ten graphene oxide films with a size of 8cm*8cm with different liquids for compounding, specifically: uniformly spray deionized water on the surface of the graphene oxide film to make the surface swell, and then multiple sheets The graphene oxide film is bonded together along the thickness direction, and the sample made by this method is marked as sample A; a layer of graphene oxide aqueous solution with a concentration of 4mg / mL is uniformly coated on the surface of the graphene oxide film, and then multiple sheets The graphene oxide film is bonded together along the thickness direction, and the sample made by this method is marked as sample B. ...

Embodiment 3

[0037] (1) Graphene oxide with a high degree of oxidation and a graphene oxide with a low degree of oxidation with an average size greater than 50 μm were respectively prepared into a 7 mg / mL graphene oxide aqueous solution, and the graphene oxide solution with a thickness of 5 mm was paved by the scraping film method. After the film is dried naturally, a graphene oxide film with a high degree of oxidation and a graphene oxide film with a low degree of oxidation are obtained.

[0038] (2) Composite ten graphene oxide films with a high degree of oxidation and graphene oxide films with a low degree of oxidation respectively, specifically: spray deionized water evenly on the surface of the graphene oxide film to make the surface swell, and then apply Multiple graphene oxide films are bonded together along the thickness direction. The graphene oxide film can be self-bonded by the force at the bonding interface, and a graphene oxide composite film with a high degree of oxidation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com