ph adjustment mechanism for water treatment

A regulating mechanism and water treatment technology, applied in the field of water treatment, can solve problems such as large amounts of water, and achieve the effects of cost reduction, reasonable compatibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

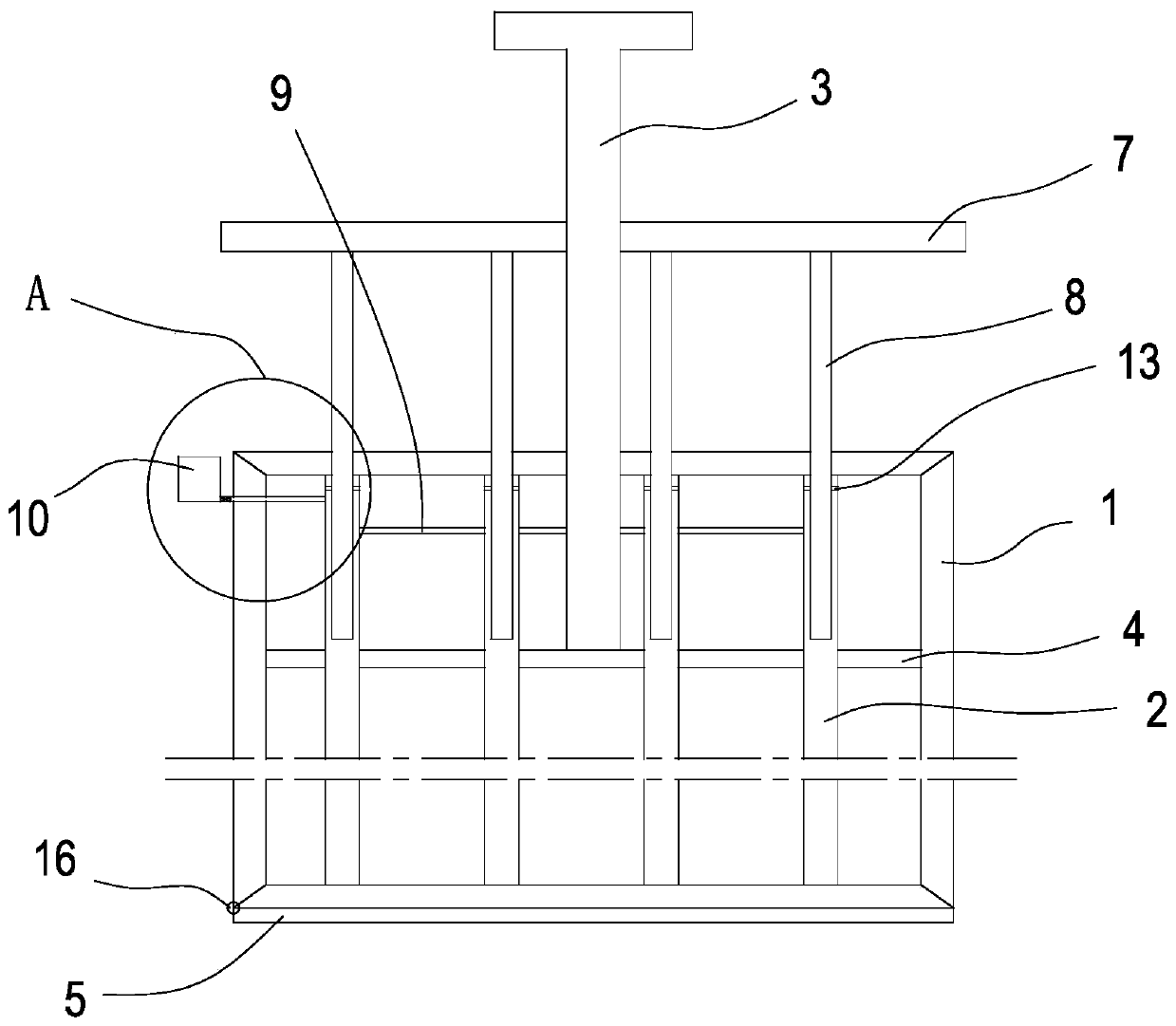

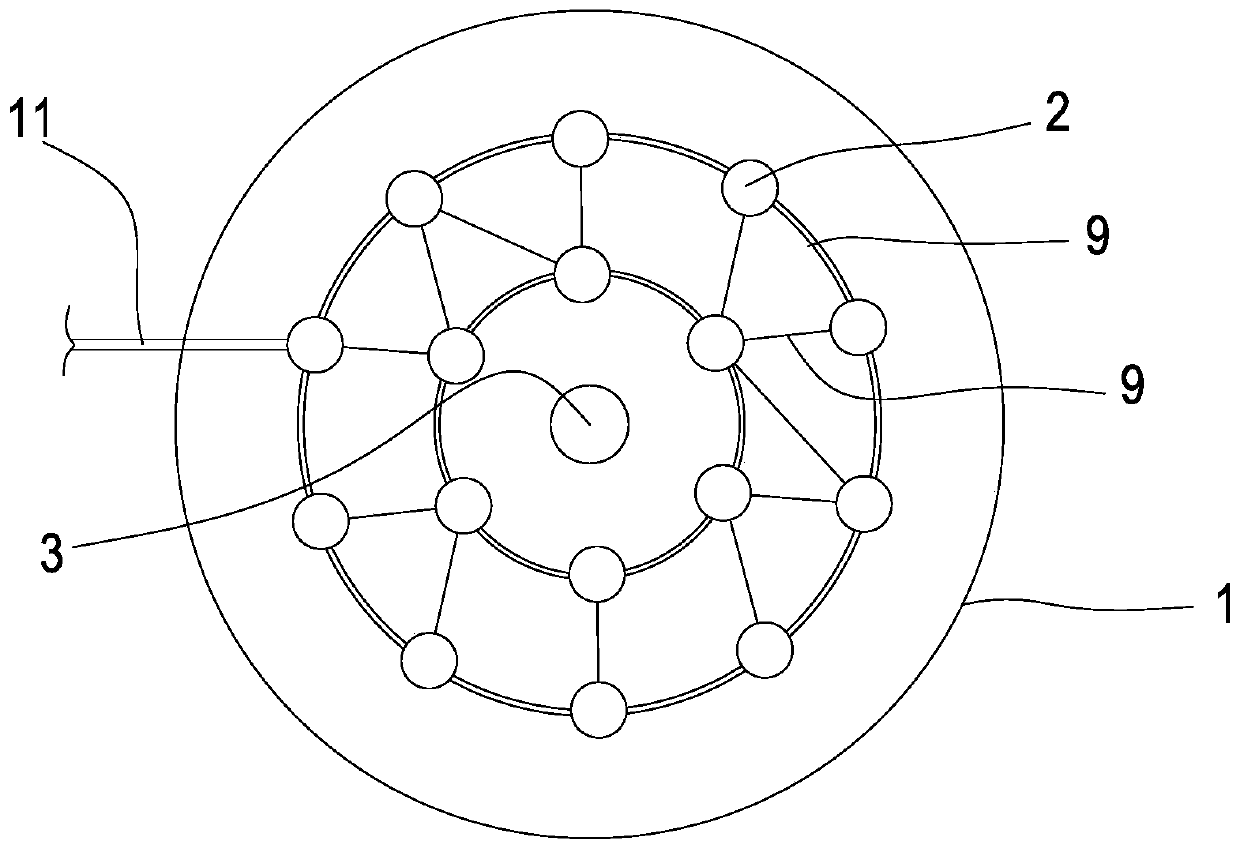

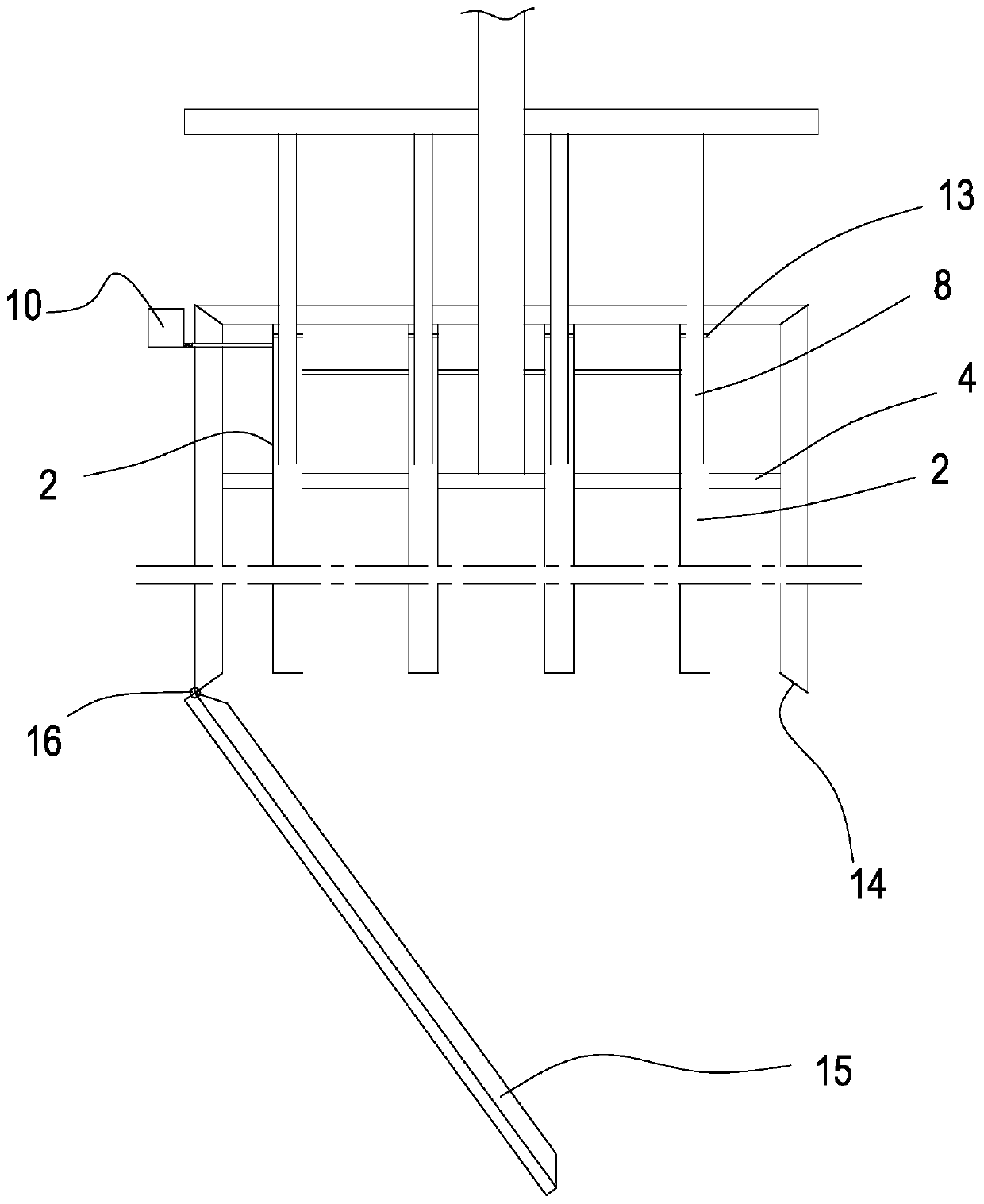

[0043] Such as Figure 7 what Figure 8 As shown, a pH adjustment mechanism for water treatment includes a self-priming neutralization mechanism 40 and a buffer assembly 33 connected to each other, and the self-priming neutralization mechanism 40 includes a self-priming inlet connected to the flow meter 32 Feed pipe 41, self-priming feed pipe 41 is provided with one-way valve assembly 42, and described one-way valve assembly 42 connects acid neutralizing agent storage tank 45 and alkali through first shut-off valve 43 and second shut-off valve 44 respectively A neutralizing agent storage tank 46, the buffer assembly 33 includes a tank 21 for containing the buffer 20, the tank 21 includes a main body tank 23 provided with a first liquid conduit 22, and A cover body tank 25 provided with a second liquid conducting pipe 24, the main body tank 23 is screwed to the cover body tank 25, and the described main body tank 23 is close to the bottom of the first liquid conducting pipe 22...

Embodiment 2

[0074] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that

[0075] Buffering agent is made up of the component of following mass parts:

[0076]

Embodiment 3

[0078] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that

[0079] Buffering agent is made up of the component of following mass parts:

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com