Anti-explosion intelligent sensor

An intelligent sensor and microwave sensor technology, applied in the field of sensors, can solve the problems of reducing the service life of lamps, wasting energy, increasing maintenance and use costs in the later period, and achieving the effect of improving their own life, good lighting, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

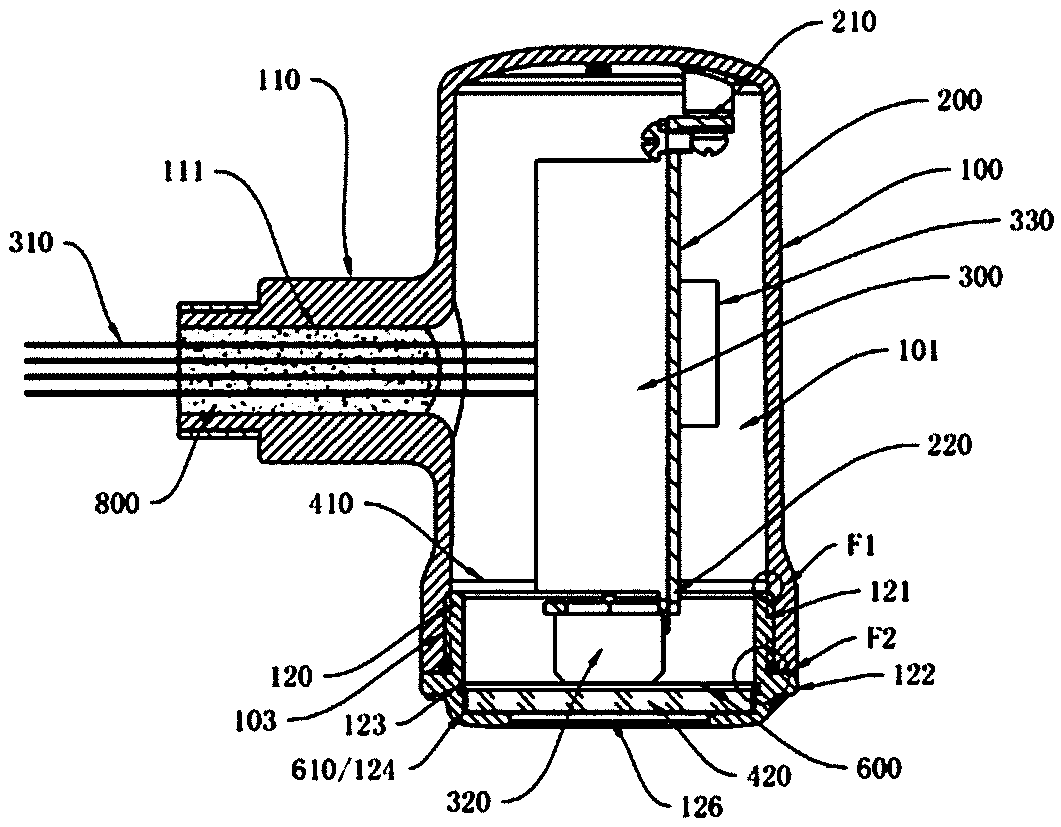

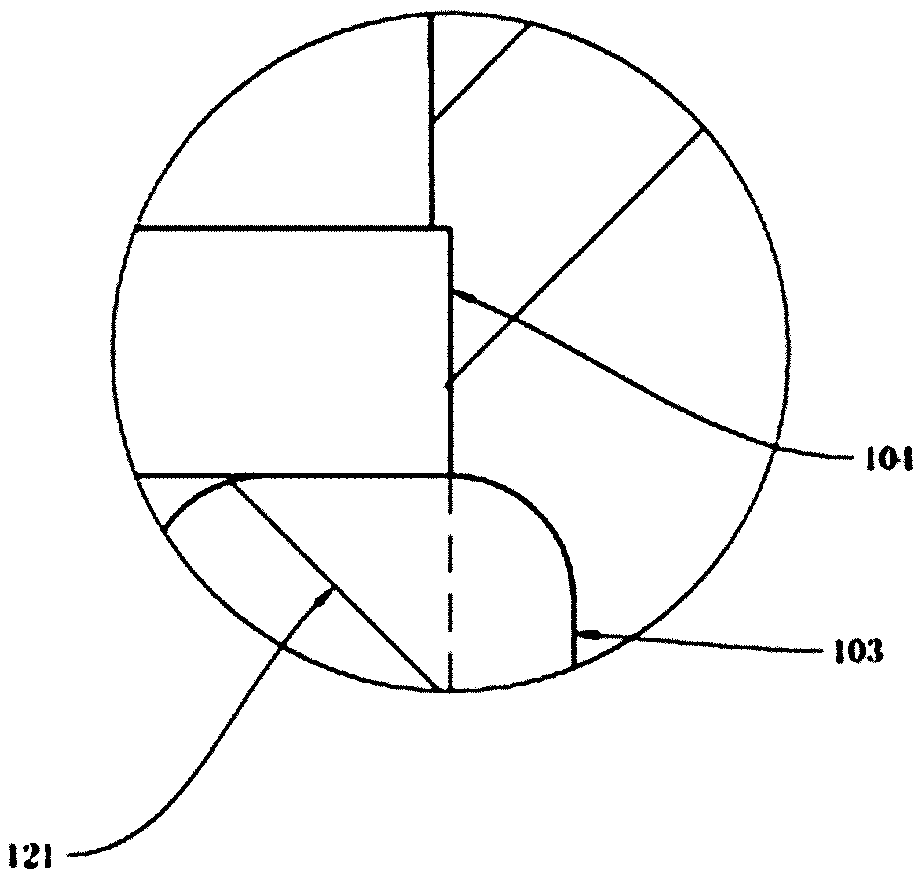

[0026] see Figure 1-Figure 3 , an explosion-proof smart sensor, including a casing 100, the casing 100 is provided with a cylinder 110, the cylinder 110 is provided with an inner cylinder 111, and the casing 100 is provided with an installation cavity 101, the The above-mentioned installation cavity 101 communicates with the inner cylinder 111;

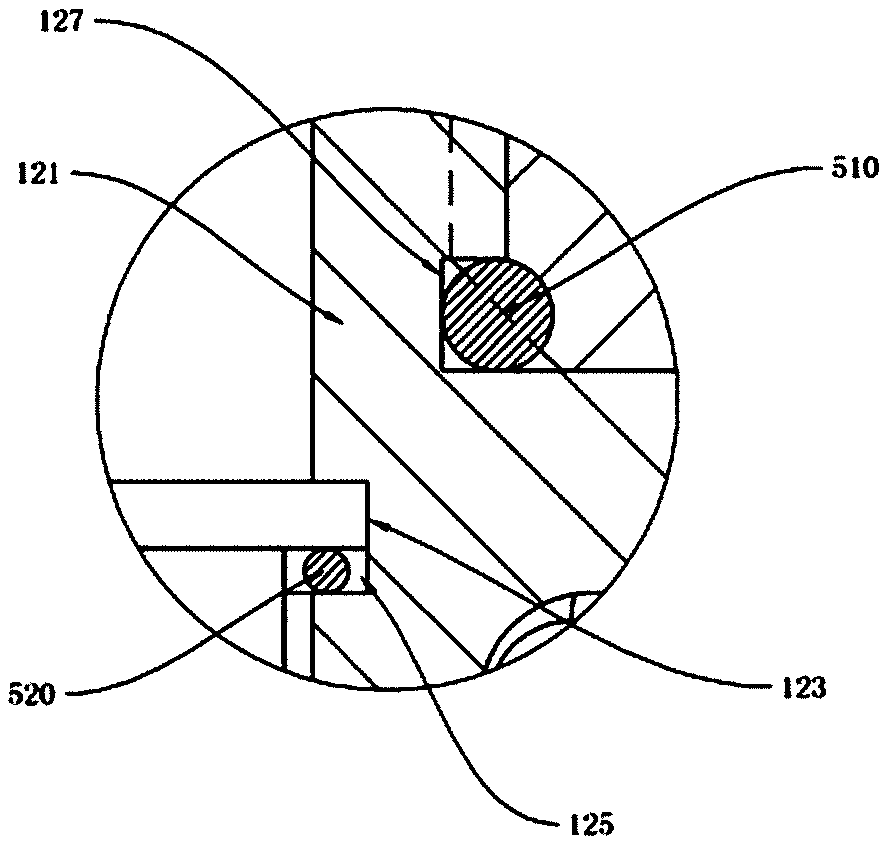

[0027] The mounting cavity 101 is fixed with a fixed plate 200, the first fixed end 210 of the fixed plate 200 is assembled and fixed with the inner wall of the installed cavity by bolts, and the second fixed end 220 is connected and fixed with the support plate 410. The left and right sides of the support plate 410 are assembled and fixed with the fourth installation groove 104 provided on the inner wall of the installation cavity. The support plate 410 is tightened by the end face of the cylinder part 121 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com