Anti-wear push-pull switch

A push-pull, wear-resistant technology, applied in the field of switches, can solve the problems of high cost of timing function and easy damage of pressing device, and achieve the effect of avoiding the replacement of push-pull rods, convenient replacement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

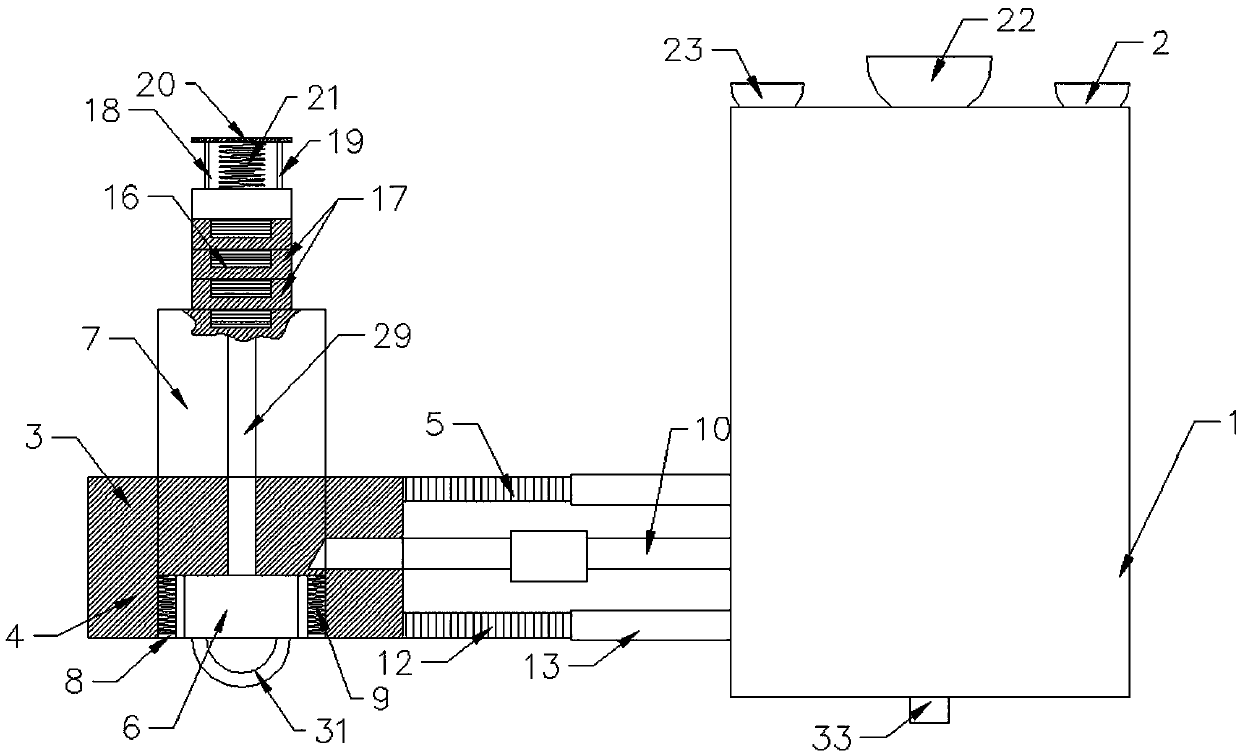

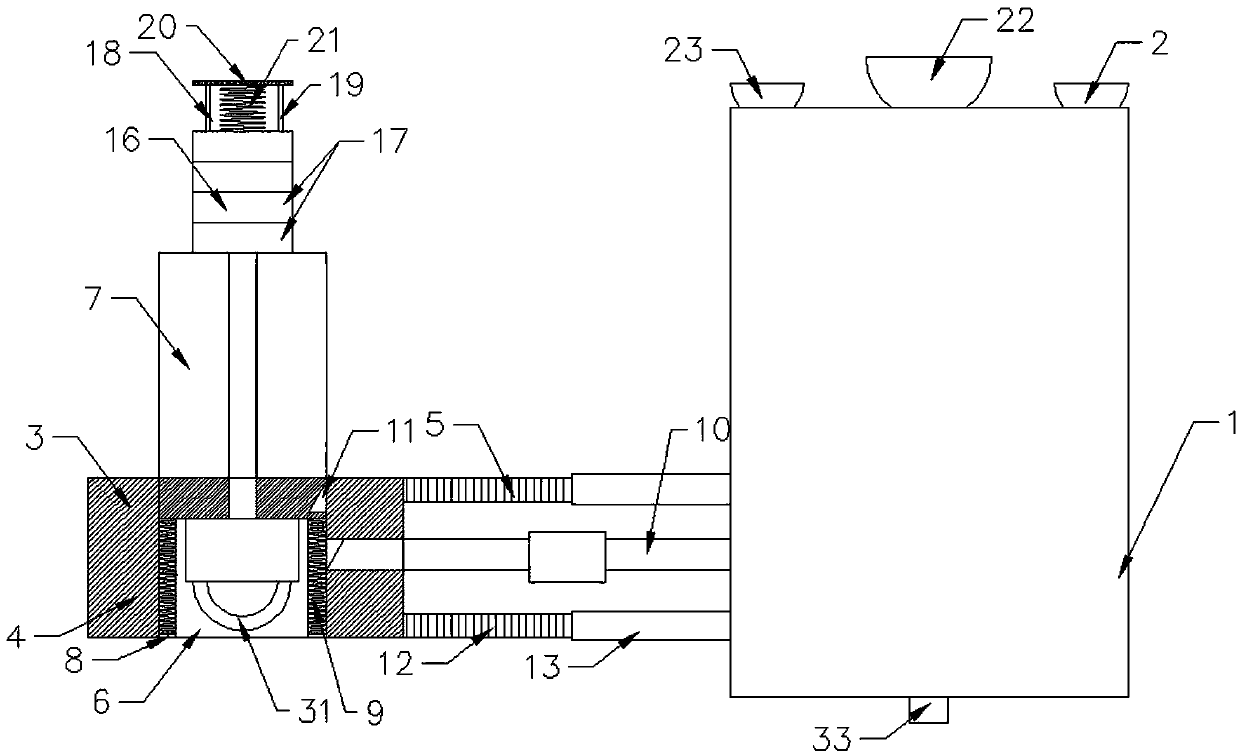

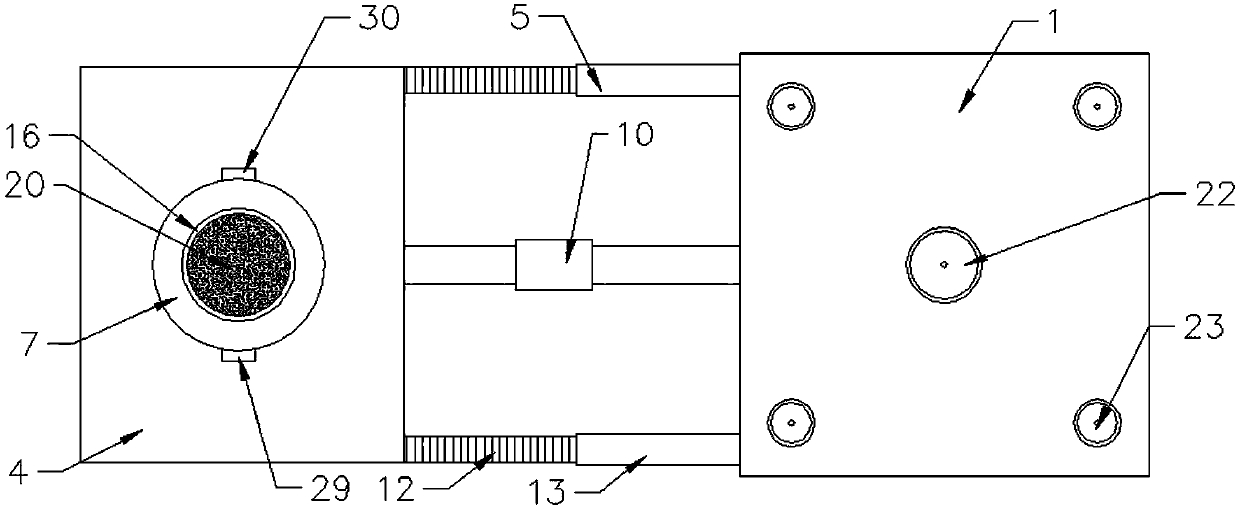

[0053] An anti-wear push-pull switch, comprising a timing switch body 1, the rear side of the timing switch body 1 is provided with an adsorption device 2 for connecting with a wall, and a side of the timing switch body 1 is provided with a switch device 3;

[0054] The switch device 3 includes a base 4, a connecting rod 5 is horizontally arranged between the base 4 and the timing switch body 1, and a through hole 6 is arranged inside the base 4, and the base 4 is located at the position of the through hole 6 and is provided with a hole suitable for the through hole 6. Equipped with a push-pull rod 7, the side of the base 4 away from the adsorption device 2 is located inside the through hole 6 with an annular baffle 8, and a first spring 9 is provided between the baffle 8 and the push-pull rod 7;

[0055] A crossbar 10 is arranged between the push-pull rod 7 and the timing switch body 1, and the timing switch body 1 controls the crossbar 10 to move in the horizontal direction; ...

Embodiment 2

[0061] This embodiment is further optimized based on Embodiment 1. The outer wall of the push-pull rod 7 is evenly distributed with a plurality of guide rods 29 parallel to the length direction of the push-pull rod 7. The base 4 is provided with a guide groove 30 corresponding to the position of the guide rod 29, and the guide rod 29 And the guide groove 30 can not only guide the push-pull rod 7 during the movement of the push-pull rod 7, but also prevent the push-pull rod 7 from rotating, so as to facilitate the connection of the groove 11 and the cross bar 10.

Embodiment 3

[0063] This embodiment is further optimized based on Embodiment 1. The push-pull rod 7 is provided with a pull ring 31 on one side of the first spring 9, so that the push-pull rod 7 can be stretched conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com