Multifunction clamping fixture with function of reorganizing and adjusting in three-dimensional space

A three-dimensional space, multi-functional technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of high manufacturing cost, large space occupation, adjustment, etc., and achieve the effect of reducing multiple combination tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

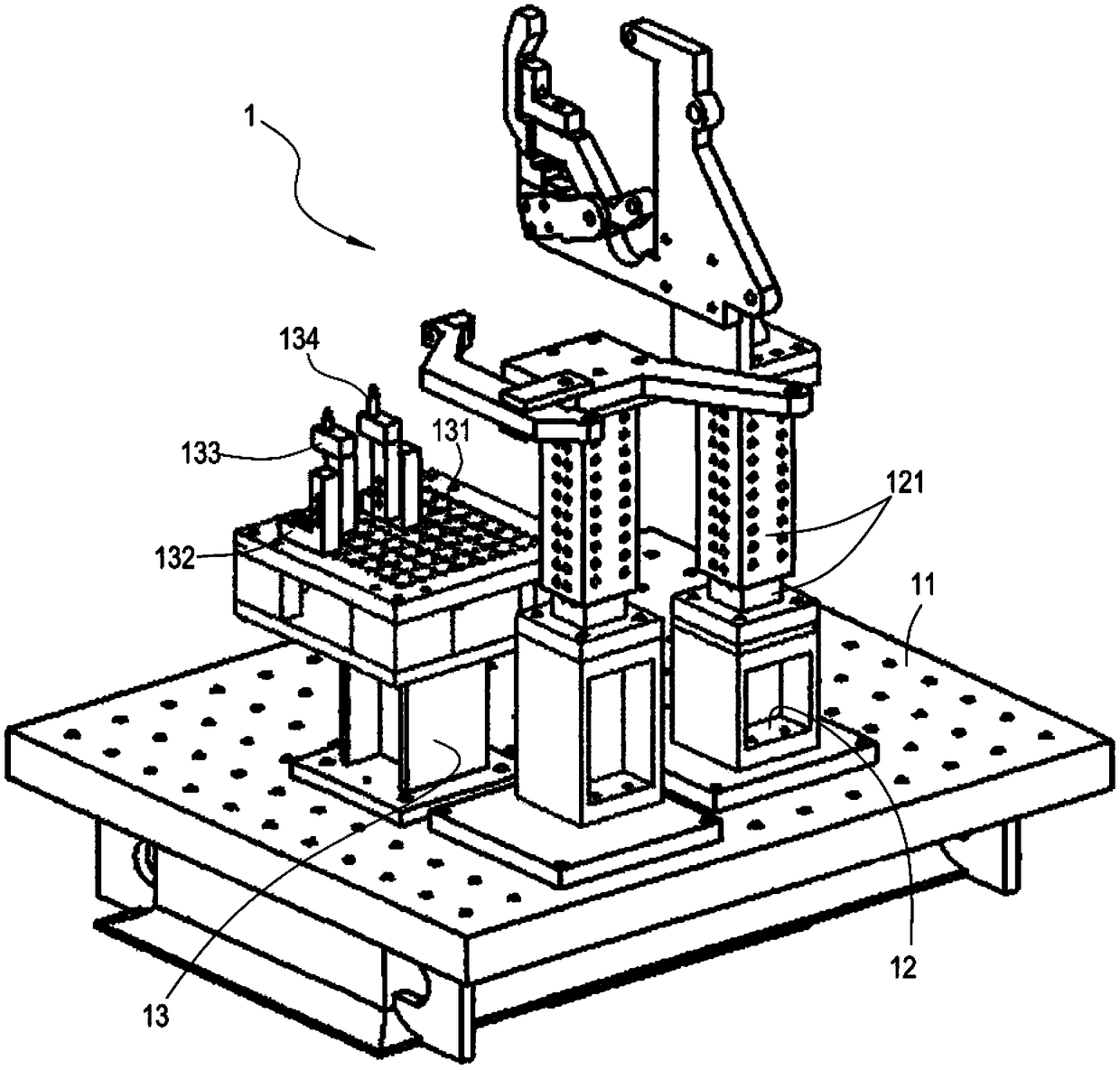

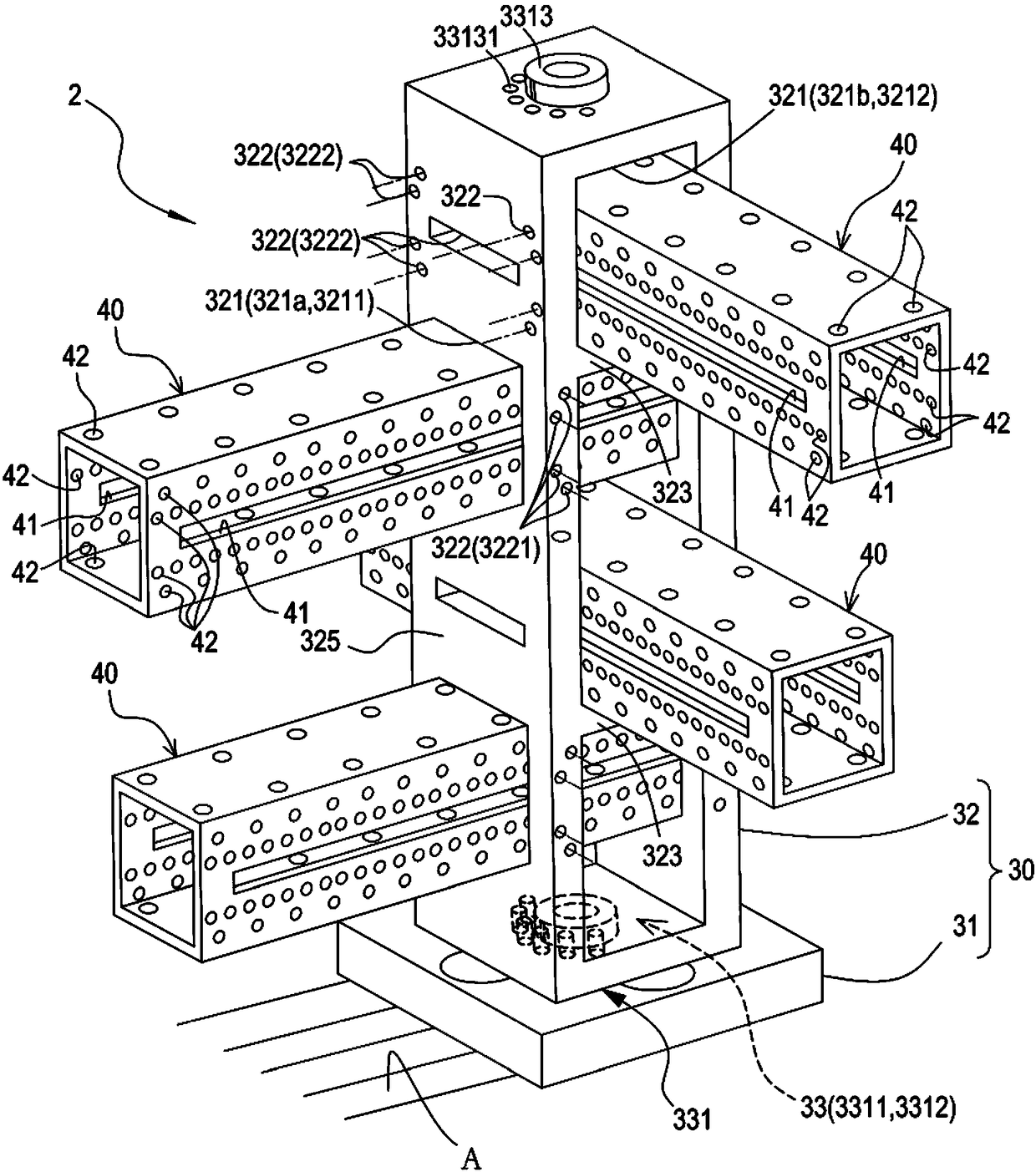

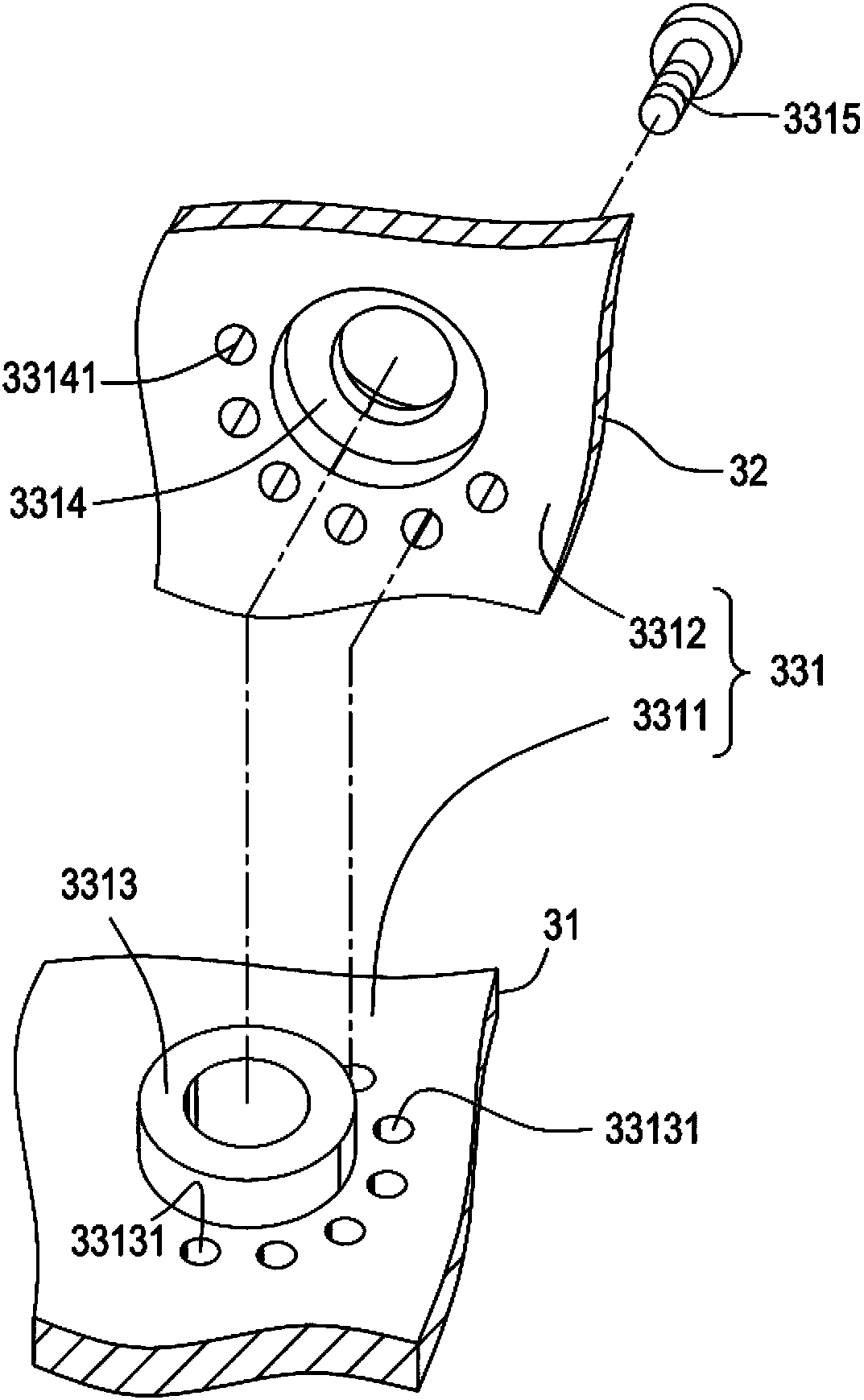

[0071] Please refer to figure 2shown. The multifunctional fixture 2 with the function of three-dimensional space reorganization and adjustment in this embodiment can be applied to workpiece welding operations, and it is detachably fixed on a welding platform A for fixing multiple welds. The workpiece is welded at the relevant position of the predetermined welding. The multifunctional clamping fixture 2 includes: a support 30 and at least one carrier 40; the support 30 has a support base 31 and a support body 32, and the support base 31 can be Detachably fixed (screw-like) on the welding platform A, the bracket body 32 can be horizontally rotated at an angle relative to the brack...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap