Components of an elevator system, elevator system and method of braking an elevator car

A technology for lifts and components, applied in lifts, transportation and packaging, etc., can solve the problems of a large number of materials and expensive rails, and achieve the effects of low production cost, good elasticity, and reduced surface pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

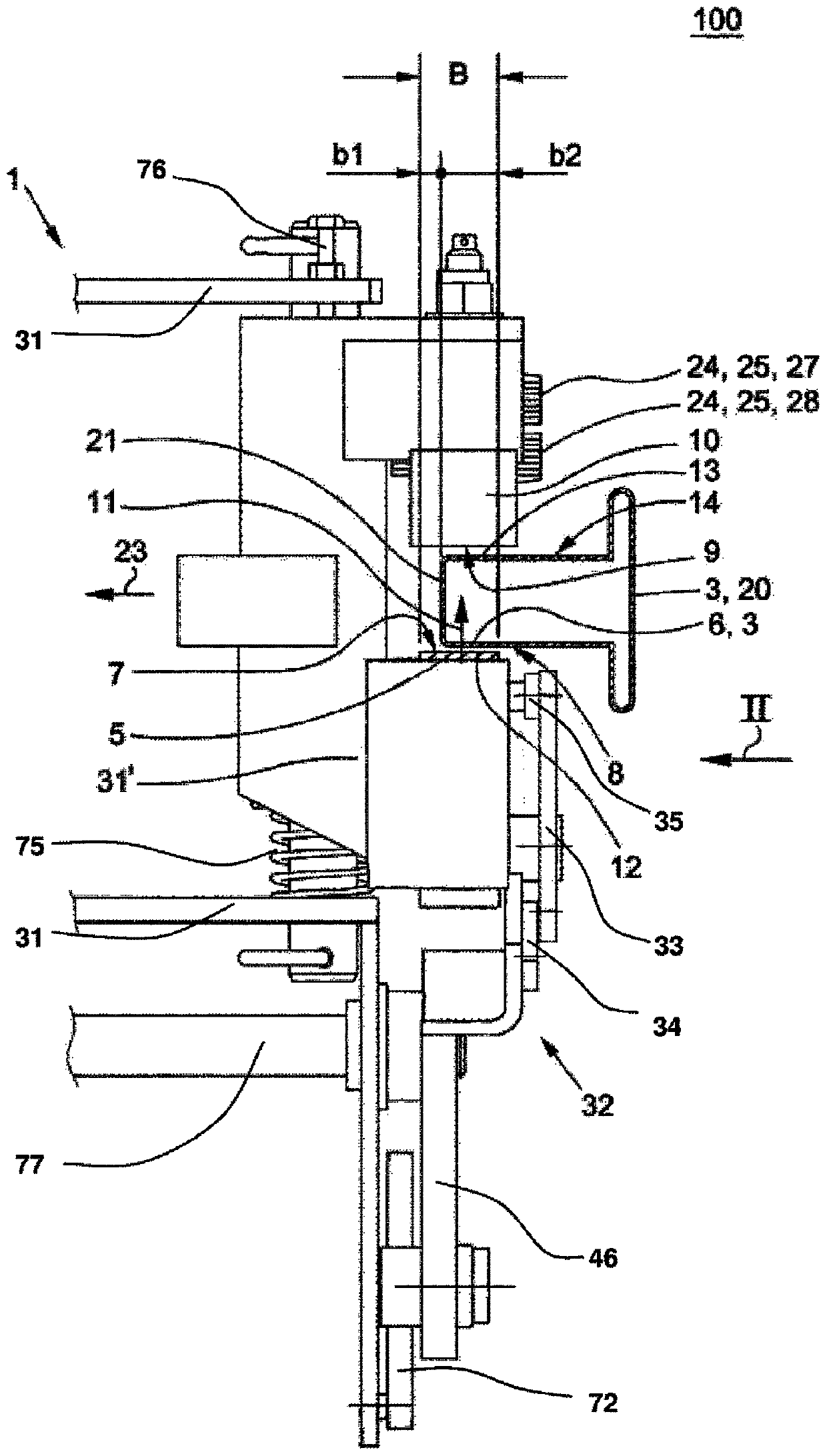

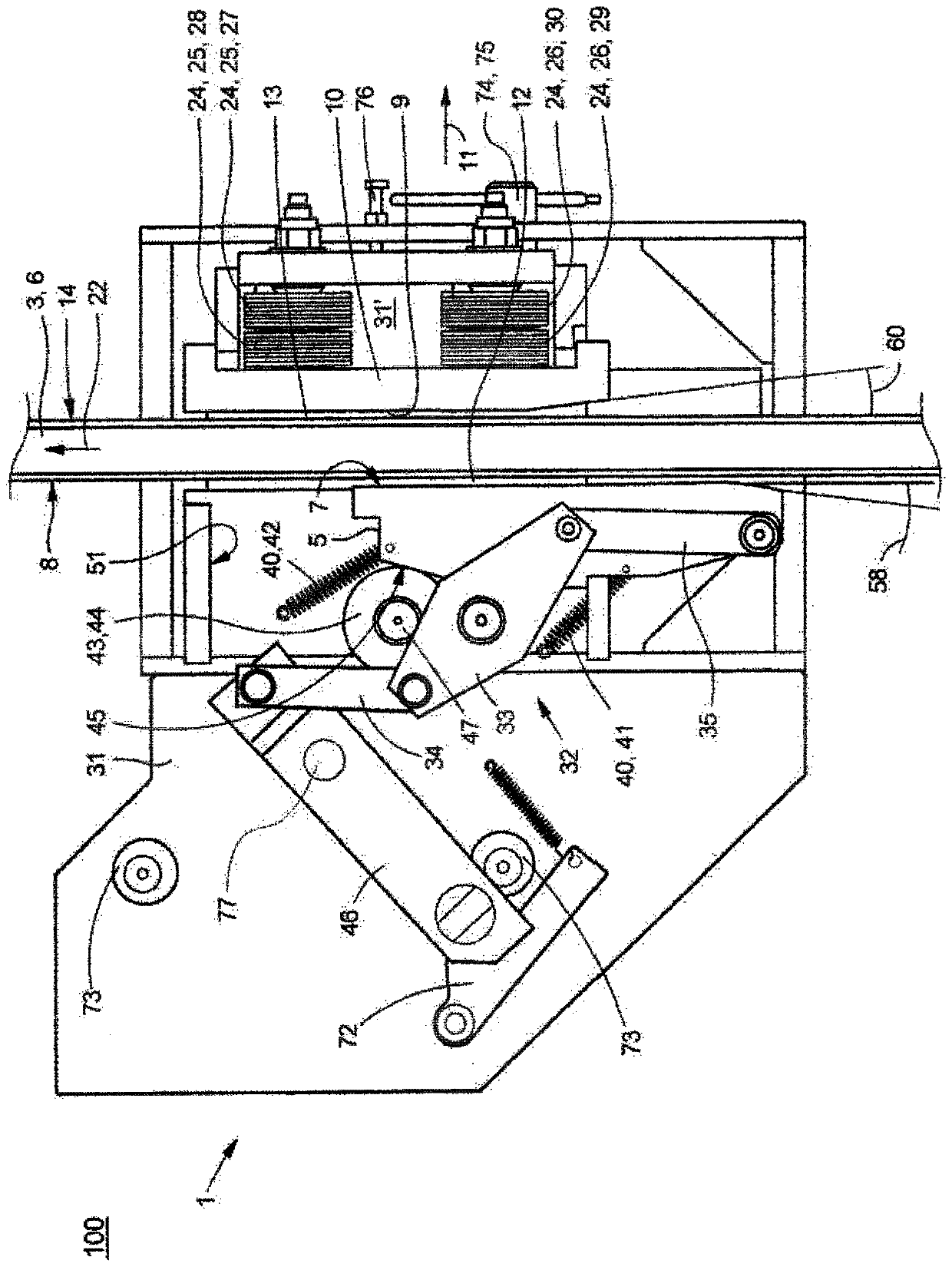

[0051] figure 1 Shown according to one embodiment of the present invention is used for elevator system 2 ( Figure 4 ) assembly 100, which includes a safety brake 1 and a track 3. In this case, the safety brake 1, which is designed as a sliding safety brake 1, serves to brake the elevator car 4 of the elevator system 2 during braking ( Figure 4 ).

[0052] During braking, the sliding safety brake 1 interacts with the head 6 of the rail 3 via the braking element 5 . In this case, the braking surface 7 or brake pad 7 faces the side surface 8 of the head 6 of the rail 3 .

[0053] Furthermore, the sliding safety brake 1 comprises a counter surface 9 formed on the counter body 10 and facing the braking surface 7 of the braking element 5 .

[0054] When actuated, the brake element 5 is adjusted in the pressing direction 11 towards the counter surface 9 . Initially, due to the disc gap 12 between the braking surface 7 and the side surface 8 of the rail 3 and the disc gap 13 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com