Method for determining corrected rotational speed signal and electric motor device

A speed signal and motor technology, applied to devices using electric/magnetic methods, using electric/magnetic devices to transmit sensing components, measuring devices, etc., can solve problems such as hindering precise adjustment of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

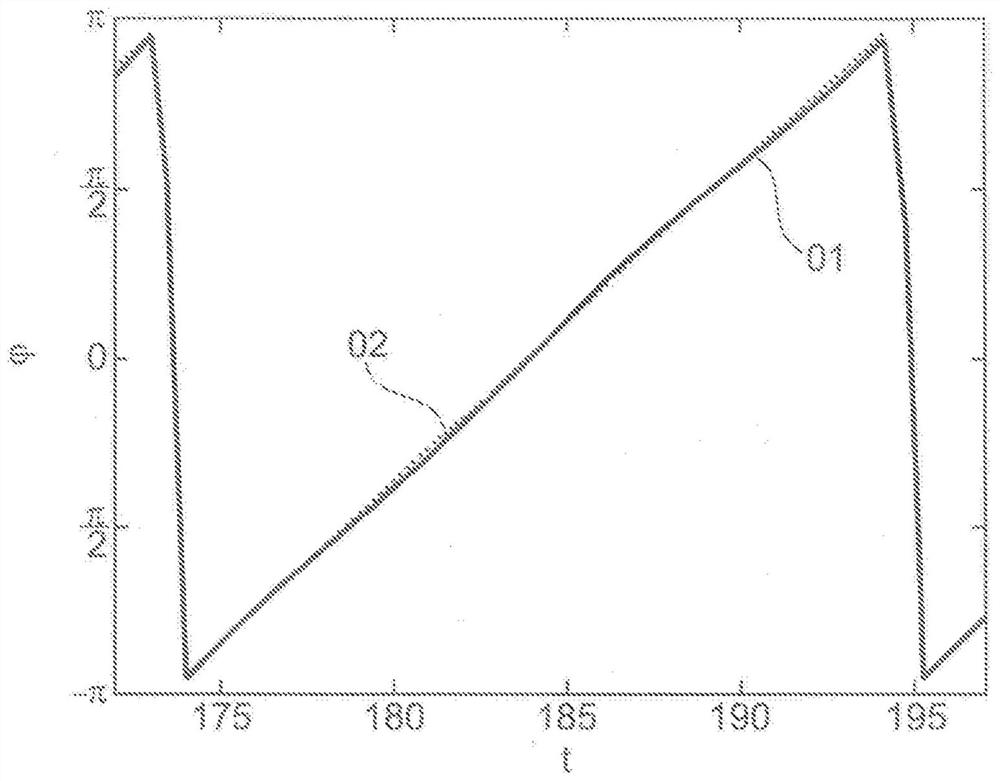

[0055] figure 1 The course of the rotational angle signal 01 output by the commutation sensor is shown, which shows the magnetic field angle as a function of time and is represented as a solid line. Correspondingly, the ideal rotational angle signal 02 is shown as a dashed line. In each revolution from -π to +π, the rotational angle signal 01 wipes out a complete cycle. A comparison between the ideal rotation angle signal 02 and the measured rotation angle signal 01 shows that the commutation sensor receives a small rotation angle error 03 (at figure 2 shown in ), which oscillates around the ideal rotational angle signal 02 similarly to a sinusoidal interference signal on the rotational angle signal 01 .

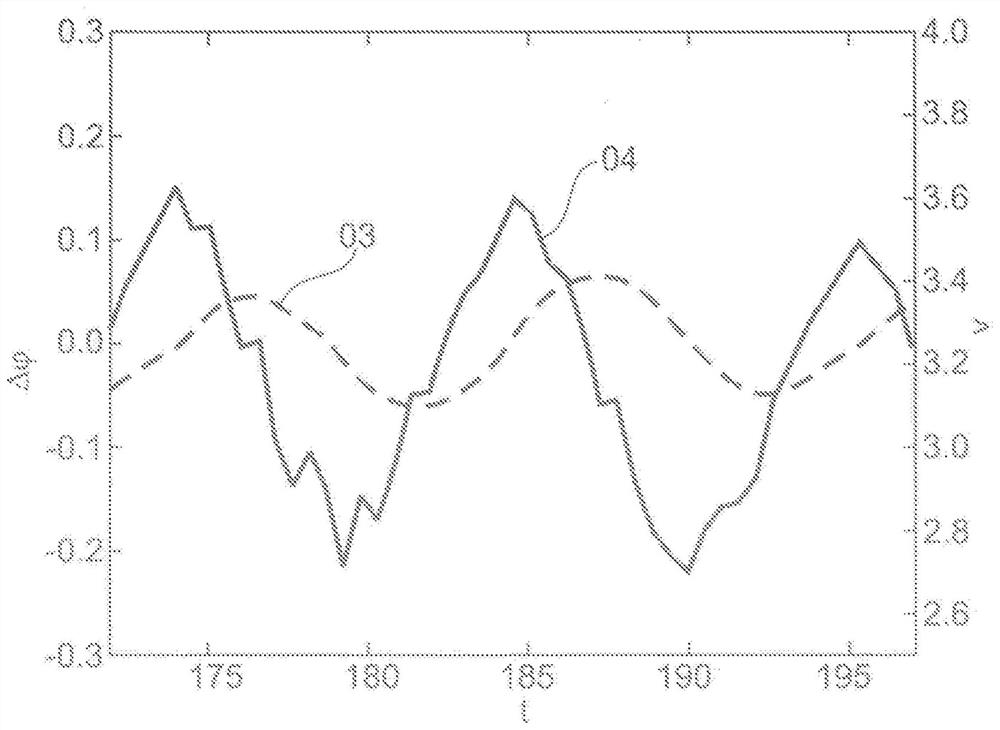

[0056] figure 2 The rotational angle error 03 is shown as a function of time as a magnetic field angle difference. Furthermore, raw rotational speed signal 04 is shown, which is obtained according to the invention by differentiating rotational angle signal 01 . It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com