Anti-blocking oxidation reactor

An oxidation reactor and reactor technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy sintering, time-consuming, and reduced efficiency of catalysts, and achieve the effect of clean catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

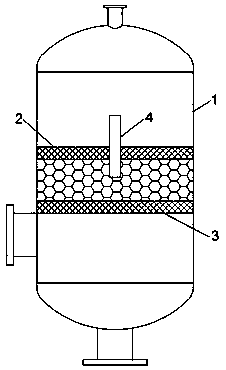

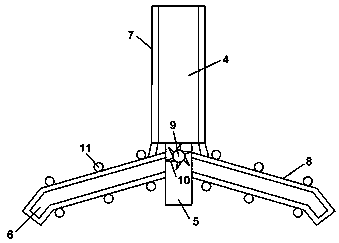

[0013] Such as Figure 1 to Figure 2 As shown, it is an anti-blocking oxidation reactor of the present invention, which includes a reactor body 1, a first grid 2 and a second grid 3 are sequentially arranged in the reactor body 1, and the first grid 2 and the second grid A metal catalyst is filled between the grids 3, a through hole is provided at the center of the first grid 2, and a detachable blowing pipe is also provided in the reactor body 1, the blowing pipe passes through the through hole and one end extends into the metal catalyst, The blowing pipe includes a fixed pipe 4, the lower end of the fixed pipe 4 is provided with a movable pipe 5, the movable pipe 5 is rotatably connected with the fixed pipe 4, and the movable pipe 5 is provided with several branch pipes 6 evenly distributed along its circumference, and the fixed pipe 4 The outside is also provided with a cleaning pipe 7, and the outside of the branch pipe 6 is provided with a cleaning branch pipe 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com