Device for detecting packing property of rubber sleeve

A technology of sealing performance and rubber cartridges, applied in the direction of measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as difficult operation, operation failure, and environmental impact of downhole operation progress, and achieve accurate sealing The effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

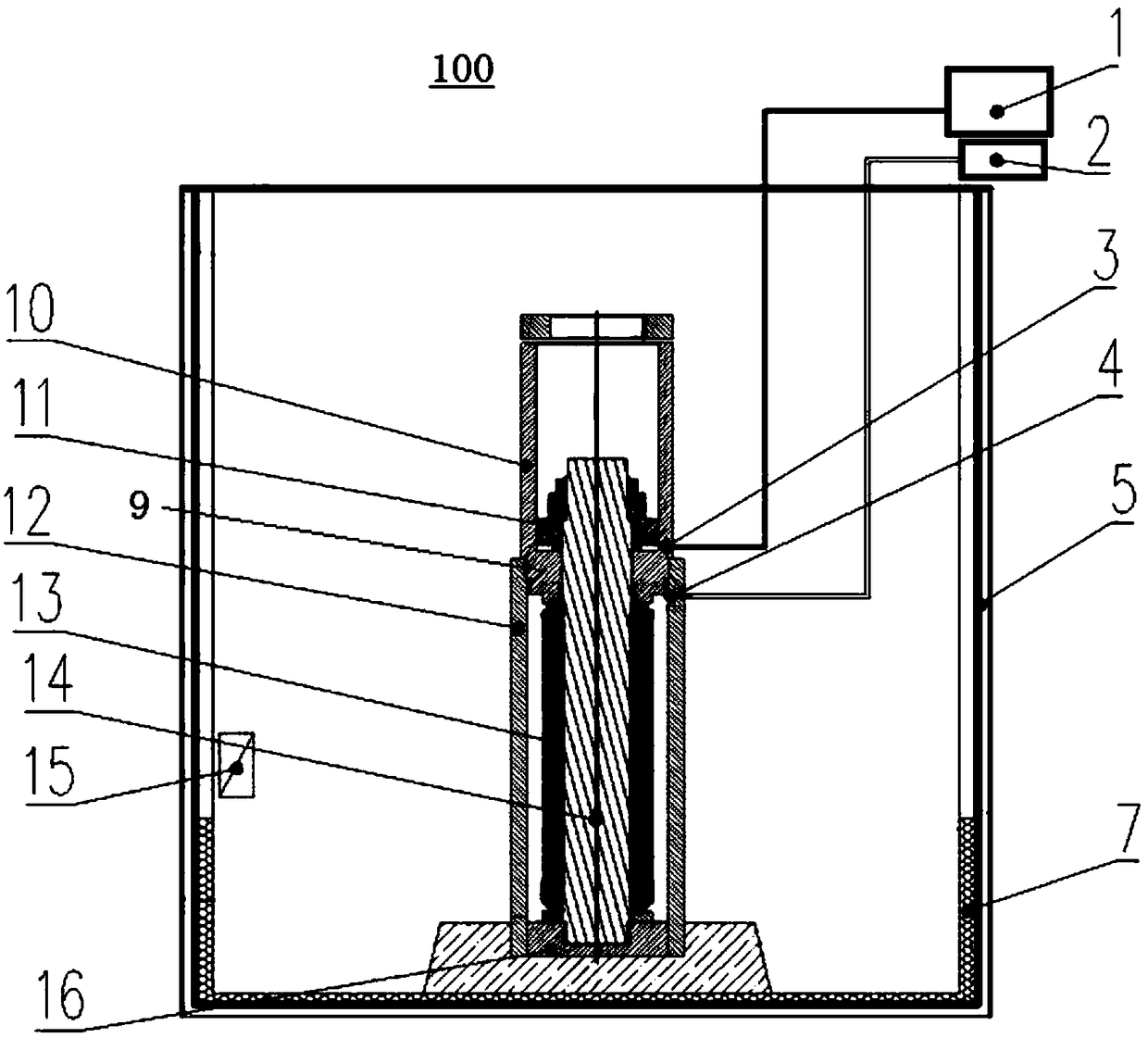

[0022] figure 1 The general structure of an embodiment of the device (hereinafter simply referred to as the device) 100 for testing the sealing performance of the rubber cartridge according to the present invention is schematically shown.

[0023] Such as figure 1 As shown, the device 100 includes a sleeve 12 and a mandrel 14 coaxially sleeved in the sleeve 12 . A substantially annular receiving annulus is formed between the sleeve 12 and the mandrel 14 . During detection, the rubber tube 13 can be tightly sleeved on the outside of the sleeve 12 . At this time, the rubber cartridge 13 will be in the containing annulus. In addition, the first pressing piece 9 and the second pressing piece 16 that seal the ends can also be respectively arranged at the two ends of the accommodating annular space, and the first pressing piece 9 and the second pressing piece 16 can carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com