Casing, electronic module with casing, and manufacturing method of electronic module

A technology for electronic modules and manufacturing methods, which is applied in manufacturing tools, electrical equipment shells/cabinets/drawers, household appliances, etc., and can solve problems such as affecting the appearance of electronic devices, not being waterproof, and affecting the electrical characteristics of electronic devices that affect structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

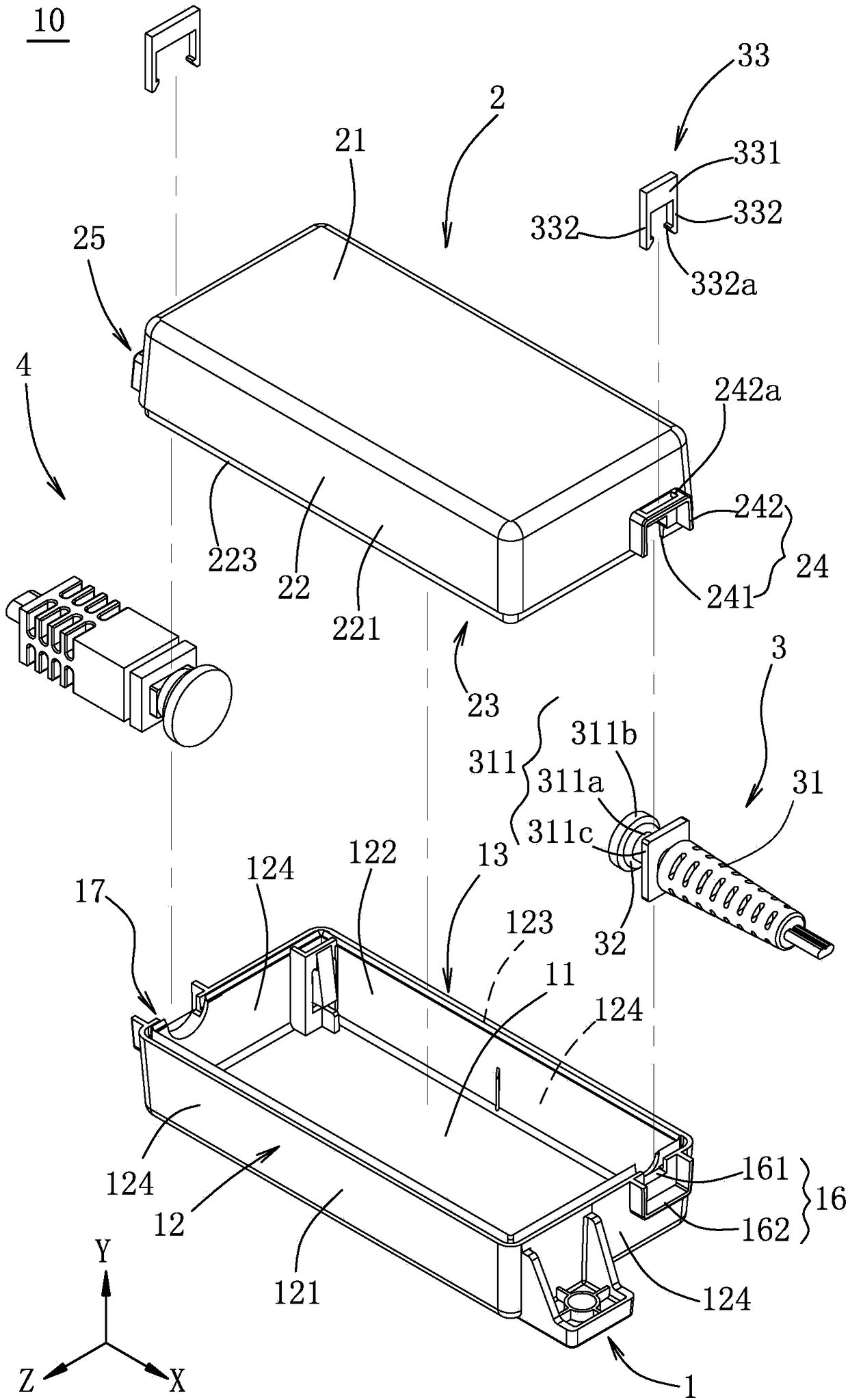

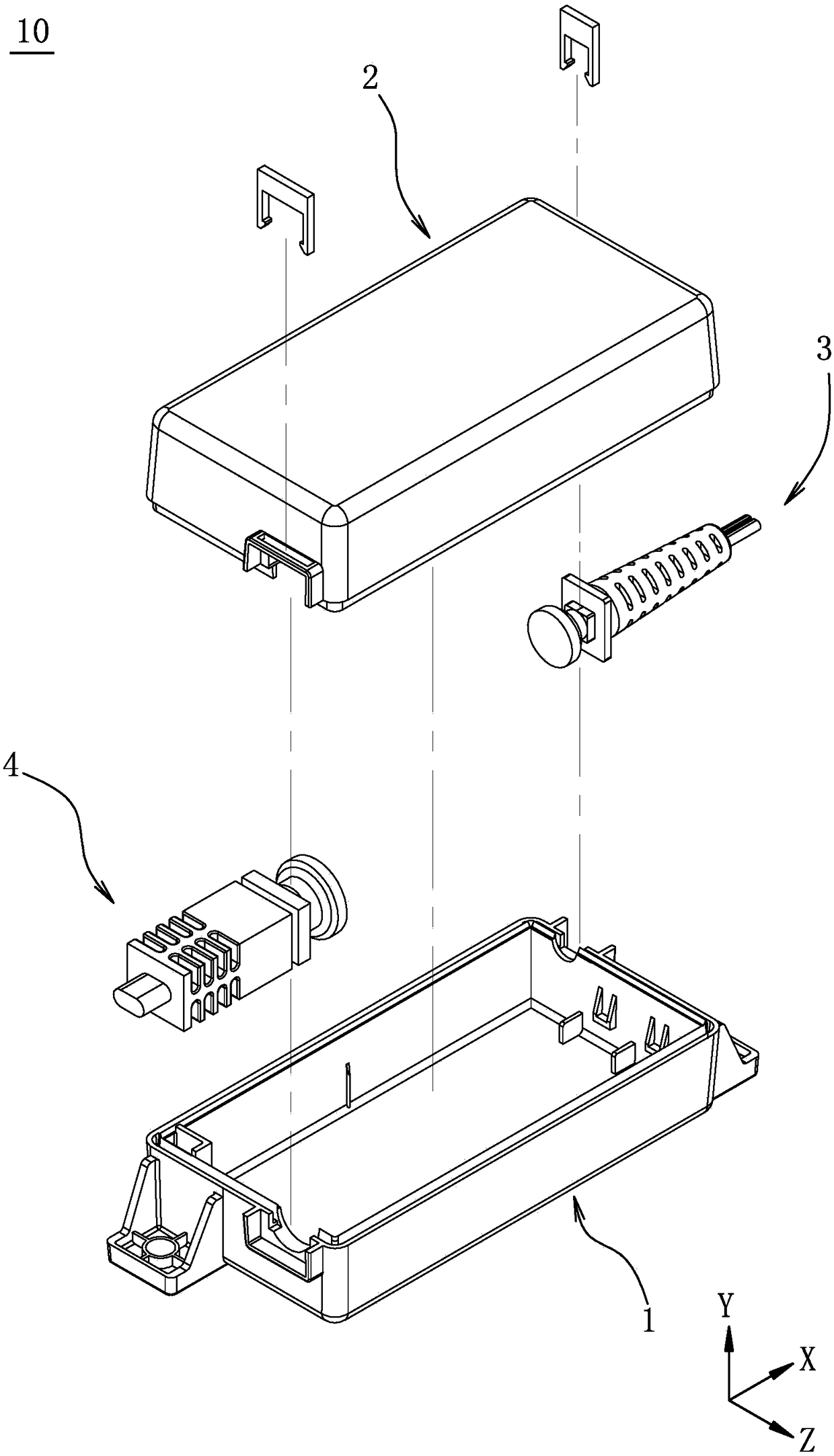

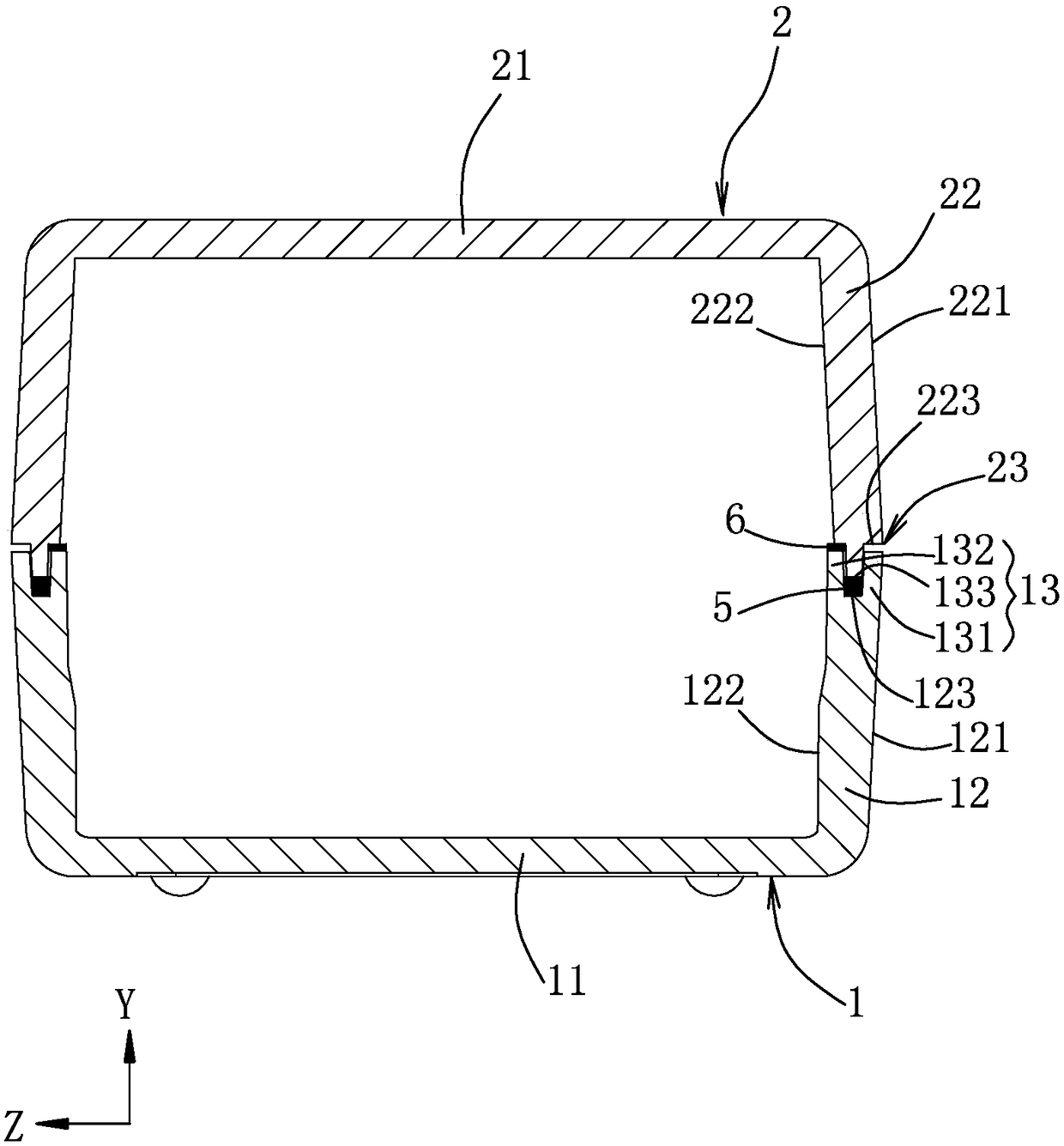

[0046] refer to Figure 1 to Figure 5 , an embodiment of the electronic module 10 of the present invention includes a first casing 1 , a second casing 2 , a first wire waterproof casing 3 , and a second wire waterproof casing 4 . Wherein, the first housing 1 forms an accommodating space for setting a circuit board with electronic components, but for the sake of simplicity, the circuit board is not shown in figure 1 and in the subsequent drawings.

[0047] The first casing 1 includes a first base plate 11 and a first surrounding wall 12 connected to the first base plate 11 . In this embodiment, the first surrounding wall 12 of the first casing 1 is approximately in the shape of a square surrounding and has four side wall portions 124, but in other implementations the first surrounding wall 12 can also be in other shapes. , such as circles, other polygons, and so on. The first surrounding wall 12 has a first outer wall surface 121 and a first inner wall surface 122 on the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com