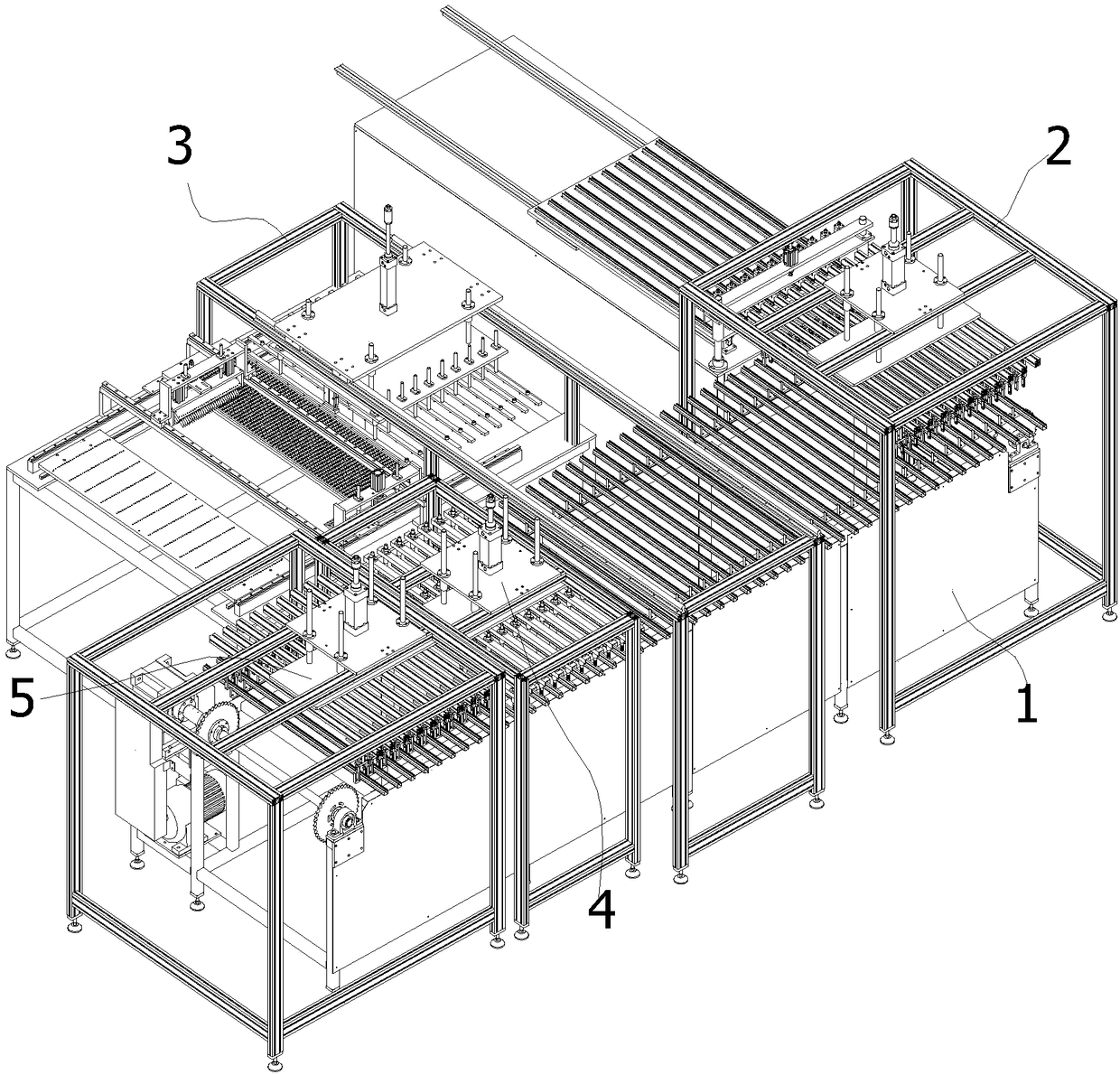

Dispensing mechanism and light strip automatic pasting device

A dispensing mechanism and dispensing machine technology, applied in lighting devices, devices for coating liquid on surfaces, light sources, etc., can solve problems such as different gestures of assemblers, manual or semi-automatic production processes, and low work efficiency, and achieve guaranteed Consistency of quality and products, high work efficiency, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

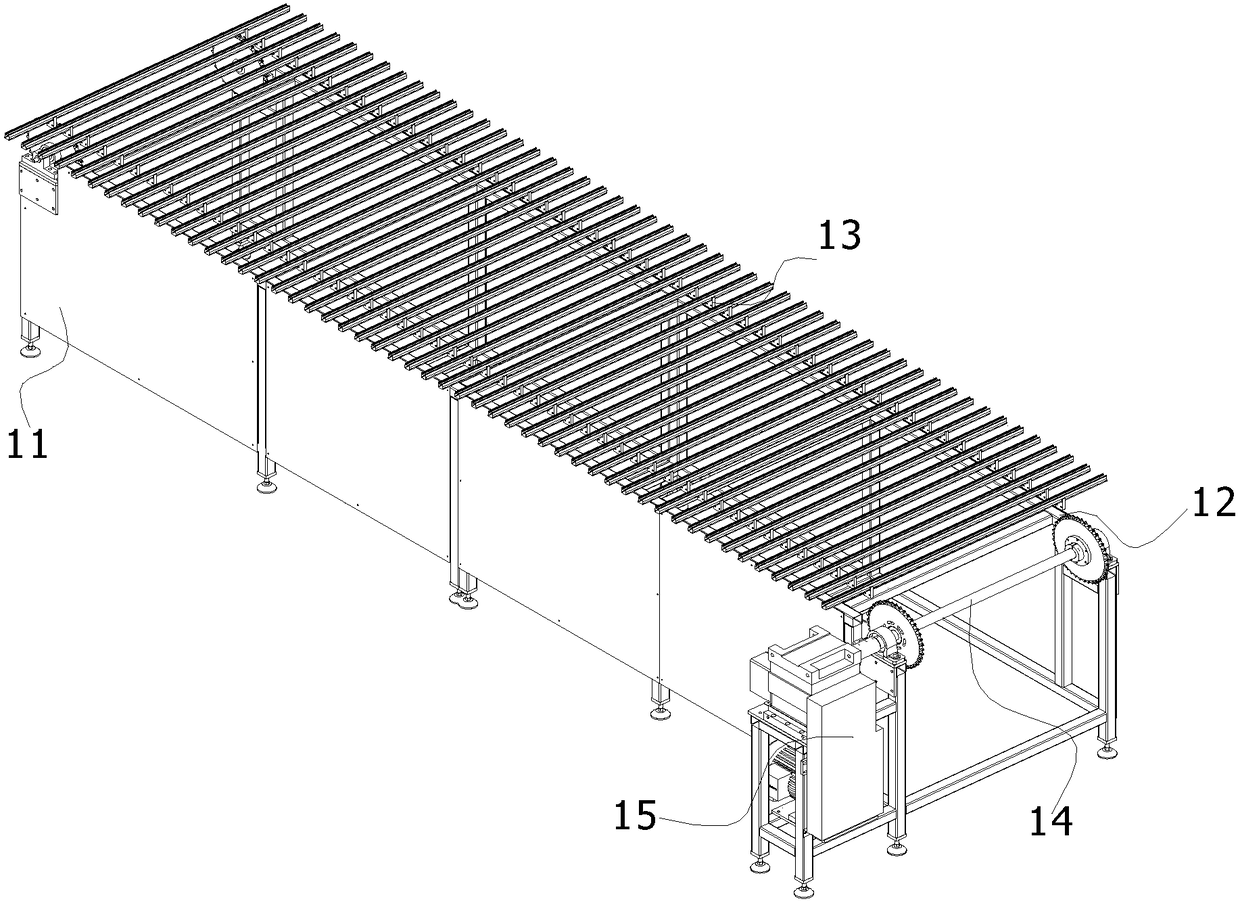

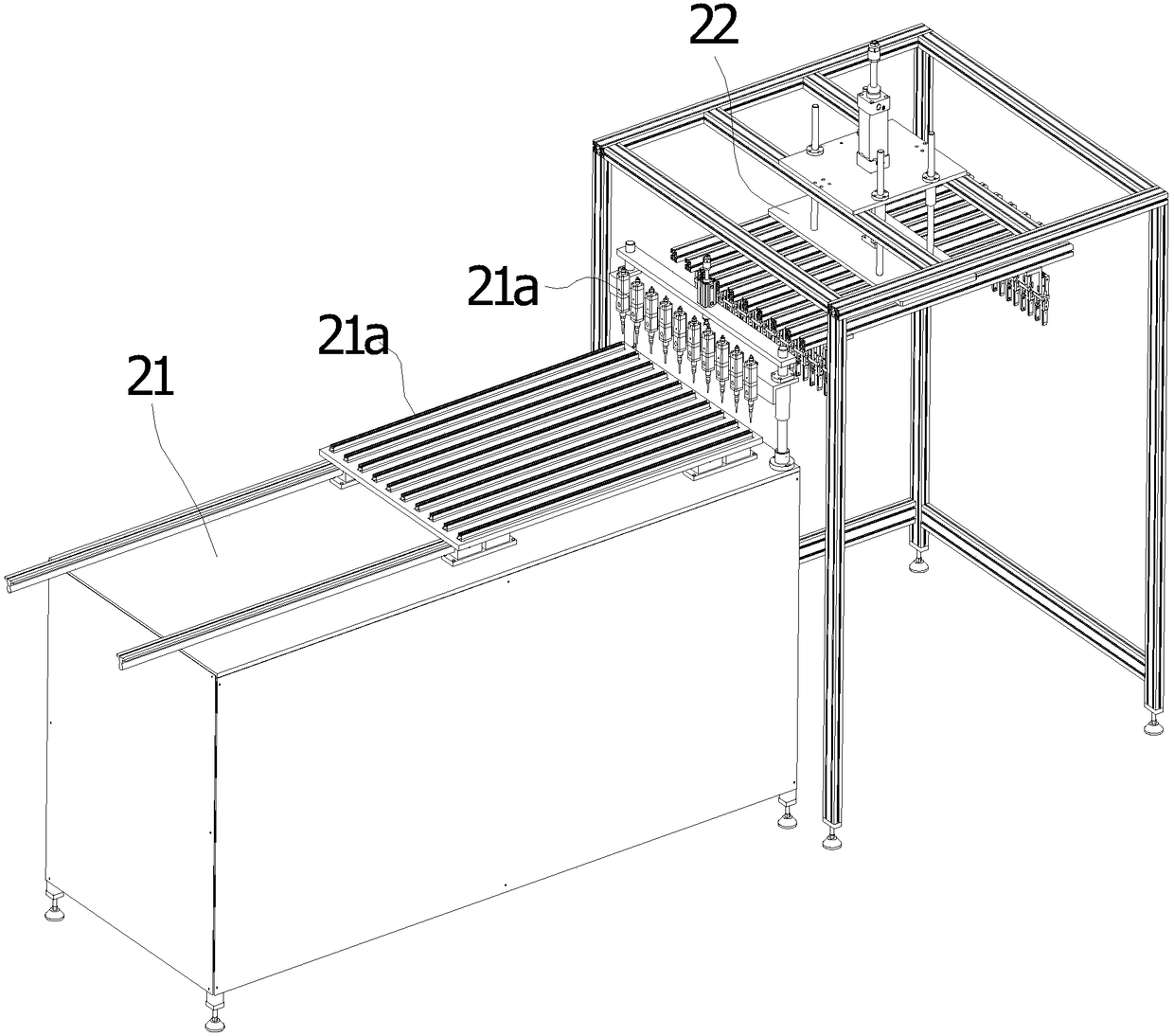

[0047] Below in conjunction with accompanying drawing, invention is described in further detail.

[0048] Such as image 3 As shown, the dispensing mechanism includes a glue dispensing machine 21. The glue dispensing machine 21 includes a glue dispenser 21a and a lamp stand fixture 21b; the glue dispenser 21a and the lamp stand fixture 21b are all arranged on the frame, and the lamp stand fixture 21b The glue dispenser 21a is configured to position a plurality of light frames, and can move to approach or move away from the light frame fixing member 21b. The glue dispenser 21a is configured to dispense glue to a plurality of light frames.

[0049] Glue dispenser 21a comprises dispensing head 216 and driving part, and driving part is located on the frame, and dispensing head 216 is connected with driving part, and driving part comprises first balance plate 214 and second balance plate 215, and the two balance plates The plates are connected by air cylinders, and the dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com